New South Wales-based startup Key Energy has installed a 8 kW/32 kWh three-phase flywheel mechanical energy storage system at a property in the Sawyers Valley, just east of Perth.

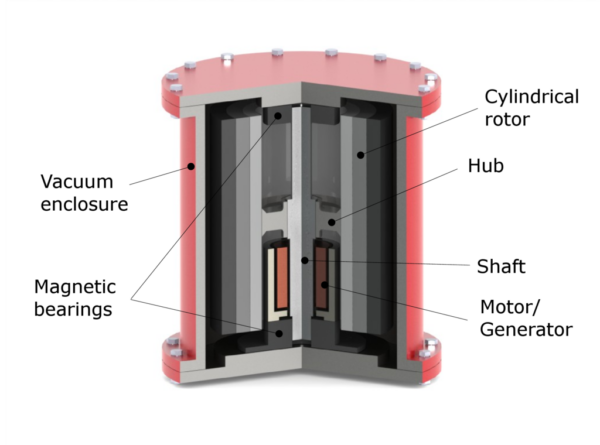

The installation involved a single flywheel, which stores energy mechanically meaning it has no fire risks, can run around 11,000 cycles without capacity degradation and boasts a 20-year to 30-year lifespan. While these systems have low energy density, they are substantially more durable than lithium-ion based chemical batteries.

This was a major drawcard for the owner of the Sawyers Valley property, who wanted a system that did not pose a fire risk, could power their three-phase loads and provide energy security as blackouts frequently affect the area.

The project marks Key Energy’s fourth installation, with another two expected to be commissioned this year. In total, the company has installed around 16 flywheel systems with over 300 kWh of capacity, including at a boarding school and at gas company APA Group’s commercial off-grid device stations.

Key Energy says it aims to leverage this residential flywheel installation, as well as future projects, to qualify its technology for Western Australia's Stand Alone Power System (SAPS) program, run by state-owned utilities Western Power and Horizon Power. The program is part of the state’s broad strategy to replace its stringy regional network of poles and wires with renewable standalone alternatives, which usually include a solar array, battery and last-resort diesel generator. These systems have been found by the state to be far cheaper and significantly reduce carbon emissions.

Flywheel battery systems are usually installed underground – a lengthy and costly process. Key Energy previously worked with the University of Technology, Sydney (UTS) to develop an above-ground enclosure for its storage systems. Key Energy says this has allowed it to shorten install times from one to two weeks with underground systems to just two days in the Sawyers Valley project.

Key Energy says it is also developing additional functionality for the flywheel, paving the way for virtual power plants (VPPs) which it believes could capitalise on the flywheel system’s robust cycling characteristics and long lifespan.

Key energy, founded in 2018, is based in the Sydney suburb of Chippendale and has a test site in nearby Alexandria. Since launching, it has attracted funding from the New South Wales government, City of Sydney and Energy Lab.

Key Energy’s flywheels are sourced from US-headquartered company Amber Kinetics, though the rest of the battery system is believed to be manufactured in Australia.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

There is a good reason why these units are normally built underground. Such flywheels can fatigue and disintegrate into high energy projectiles. These fragments can fly off in different directions with a considerable amount of destructive energy. The design of the containment vessel has to be substantial to contain these fragments within the vessel and to prevent them from flying off into the surrounding area, potentially causing a lot of damage. So they are normally built in the ground to catch these high energy fragments and to prevent them causing external damage. It’s obviously cheaper to build a unit above ground. However, they are inherently unsafe as it’s far more difficult to guarantee the containment of the fragments. The safety aspects of building a unit above ground have not been addressed in the article. How have the manufacturer address this key safety issue?

Now that’s a real good question Dr. Robinson and needs to be addressed.

Fancy writing that whole article and not answering the obvious question readers will have regarding the cost of these units, both TCO and up front cost.

I suppose the containment is achieved by that thick concrete cylinder (the white painted one)

Thanks Stephen, spot on. This design is just cheap at the cost of safety.

More over: the claimed reduction in installation is still several times what is required for a 32kWh commercial LiFePo4. And what about the concrete foundation? Also installed within the these 2 days?

Last but not least: it is well known that the round trip efficiency of these AC coupled devices is substandard.

Why do you say that, Hans? According to the information available online, modern flywheels – vacuum sealed and magnetically levitated – have a round trip efficiency equivalent to batteries reaching up to 90%.

I second Dr Robinson’s concerns. Eagerly anticipating a response.

While described as being “low energy density”, that seems to be a *relative* term. The size of the unit pictured – which includes the added above-ground containment enclosure – seems quite modest. Yet the specifications listed suggest the unit offers storage equivalent to 2½ Tesla Powerwalls. Furthermore, considering an underground installation mostly makes use of otherwise unusable space, it could be argued that the real spatial “opportunity cost” of the unit is similar to wall mounted batteries.

All things considered, I’m surprised units like this aren’t more popular for some domestic installs as well…

It has a 3 phase generator, as you draw energy from it the frequency drops plus the voltage drops.

What ever is its load does not have to care about frequency and voltage drops.

This is a mechanical capacitor, as soon as a load is applied frequency and voltage drops.

Wonder how much power it takes for the magnetic bearings since it has to be consumed 24 hours a day?

How often does the vacuum pump have to run to take care of leaks?

Just a few thoughts

I agree with Martin. We have to get away from battery technology. It’s like a dog chasing it’s tail, so, i believe that this invention should get all the help to advance it can possibly get to advance it’s design and use as much as possible. I have lived off grid for 30 years now, and have seen, and purchased a lot of supposedly, ‘Great’ new ideas, and, not cheap stuff, the best at the time available, and in my opinion, we must move forward, and this idea is taking us closer, i would hope. Why you so called ‘experts’ knock people who have a go, is beyond me. Have a look at the ‘latest’ battery technology, it won’t be around in a year or two, they’ll come up with something else similar, but, with a jazzy name, and, something again, that has to run through your stupid mobile phone or the likes. I hope this idea can be advanced as much as they can down the track, and, as some have said, address the safety issue, which i’m sure the developers are aware of.

This is a fascinating development in energy storage! A flywheel mechanical battery with 32 kWh capacity could revolutionize the way we store and use renewable energy in Australia. I’m excited to see how this technology will impact grid stability and contribute to a more sustainable future. Can’t wait to hear more about its real-world applications!