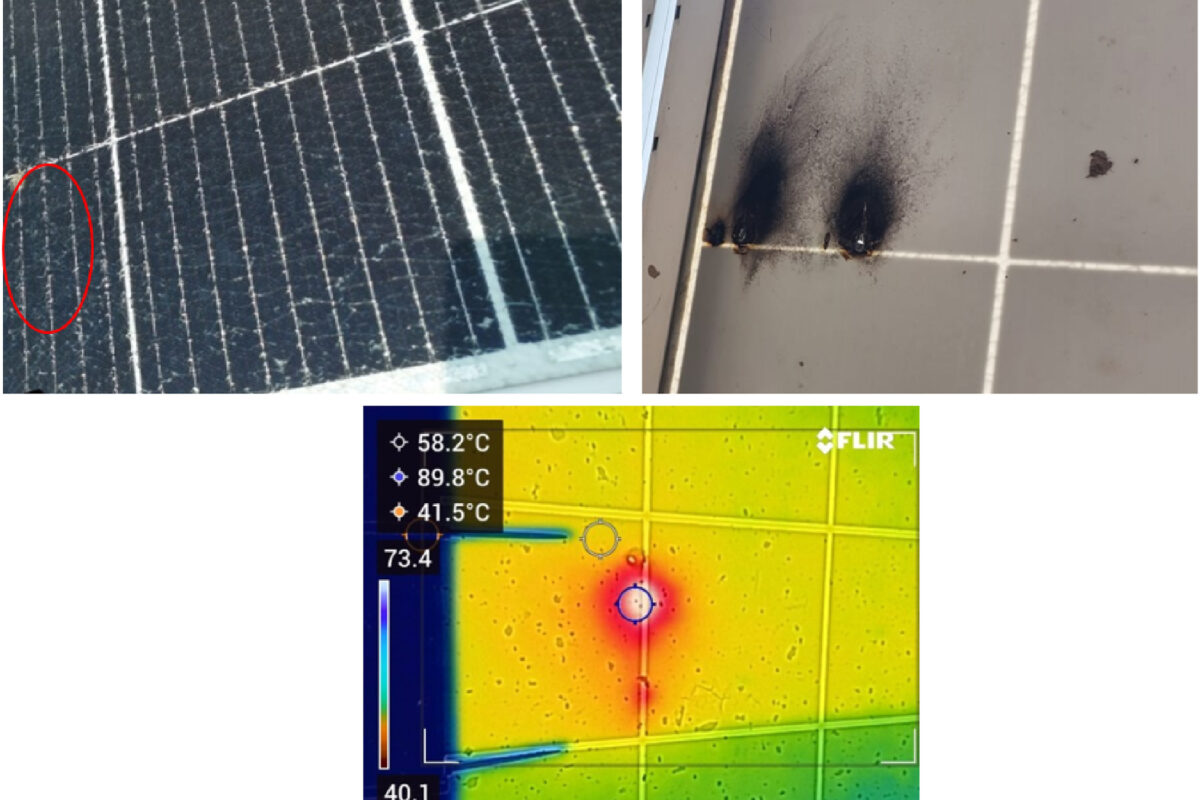

Scientists have developed an additive and treatment for perovskite solar cells, which alters their chemical structure and reduces the effects of defects and degradation mechanisms. Cells that underwent the treatment achieved initial efficiencies around 24% and maintained 98% of this after 1,000 hours of ‘1 sun’ illumination. Reference cells produced without the treatment had lost 35% of their initial performance after just 200 hours under the same illumination.

The cells also fared well under high temperature testing, retaining 97.6% of initial efficiency after more than 500 h exposed at 60 C. In this test the reference cells lost 27% of initial performance in the same conditions. The treatment and testing of the cells is described in full in the paper “Covalent bonding strategy to enable non-volatile organic cation perovskite for highly stable and efficient solar cells,” published in Joule.

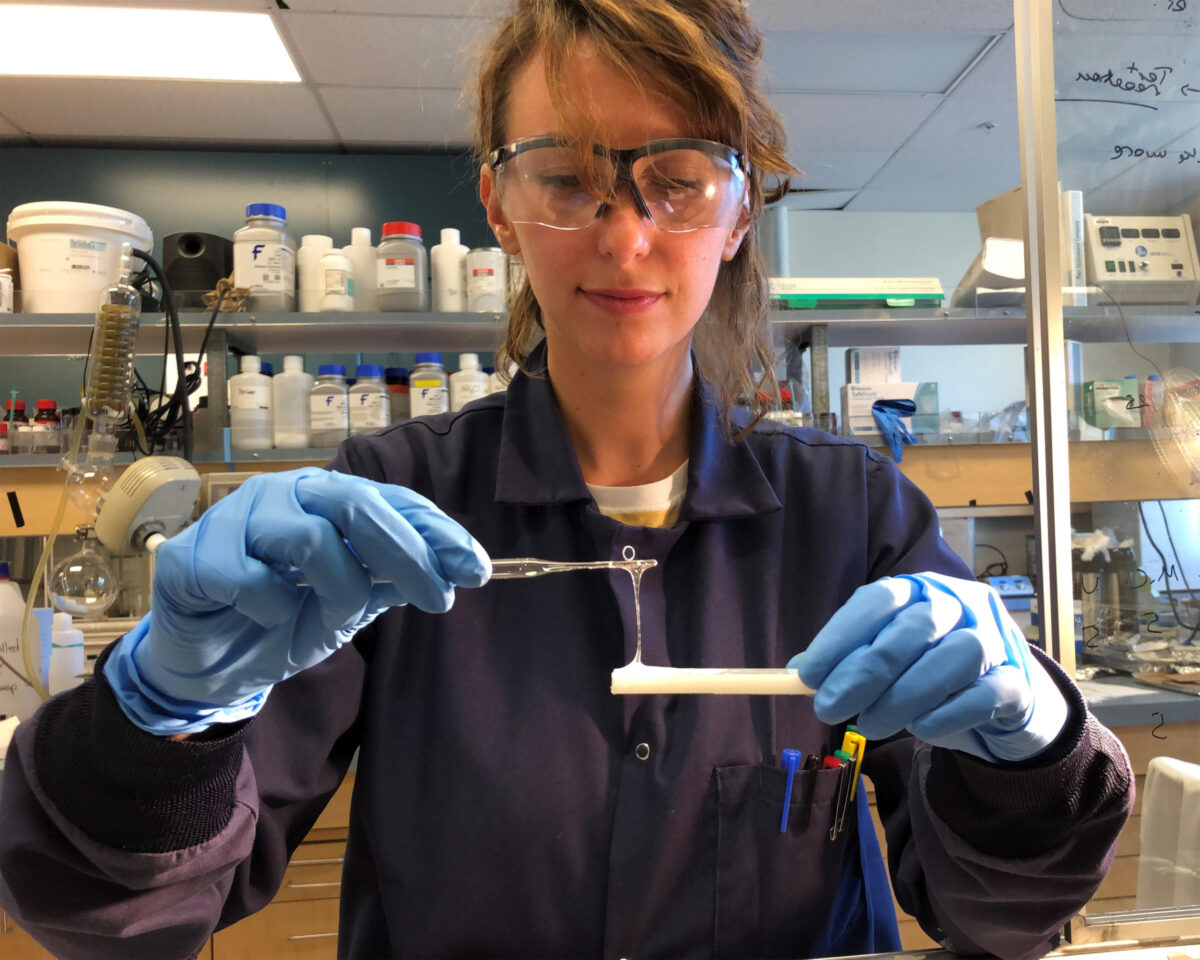

The scientists used various imaging techniques to understand how their treatment worked, concluding that bis diazirine, a polymer material present in the additive, formed covalent bonds with the organic element of the perovskite material. “…the covalent bonding strategy facilitates the ions’ immobilization, inhibits the escape of organic components, and eliminates the metallic Pb. Hence, it reveals enhanced thermal, illumination-resisting, and electrical bias-resisting properties of perovskites.”

Closer inspection

With further characterization, simulations, and comparison to devices built without the treatment, the group was able to observe the covalent bonding strategy in action and confirm its role in reducing various undesirable effects that lead to performance loss in perovskite solar cells, as well as contributing to their initial performance by reducing the appearance of defects. “This work suggests a novel and effective strategy to confine the loss of organic components from perovskites to realize highly efficient and ultra-stable perovskite solar cells.”

The cells in the study were produced using spin-coating – a process commonly used in laboratories, but not suitable for large-scale production. However, a company spun out of Victoria University in Canada, Xlynx Materials, has begun marketing the treatment under the name BondLynx, and is inviting companies working to commercialize perovskite solar cells to collaborate on further projects or to purchase the materials for use in their own trials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.