Researchers at the Nanjing University in China have fabricated an all-perovskite tandem solar cell that reportedly shows lower interfacial non-radiative recombination and improved charge extraction.

All-perovskite tandem cells – where two different perovskite cells are stacked on top of each other – promise efficiencies similar to those of tandem perovskite-silicon devices, well past the 30% mark, with better flexibility, much lighter weight, and a lower environmental impact than technologies relying on silicon wafers.

“All-perovskite tandem solar cells constructed by wide/narrow bandgap perovskite cells have the advantages of high efficiency and low cost, which is an important development direction of the next generation photovoltaic technology,” the research team's lead author, Hairen Tan, told pv magazine. “Our all-perovskite tandem solar cells can be used in power station power generation, rooftop photovoltaic, water catalytic decomposition, carbon dioxide catalytic decomposition, and space applications due to their high open circuit voltage and high efficiency.”

The scientists also explained that in previously built all-perovskite tandem devices perovskite suffered from low open-circuit voltage and fill factor due to the high defect density on the surface of the mixed narrow bandgap perovskite films based on lead and tin (Pb-Sn), which causes cause serious non-radiation recombination loss at the interface between the perovskite absorber and the buckminsterfullerene (C60) electron transport layer (ETL).

“It is a common strategy to reduce the interface recombination loss of perovskite cells by depositing a two-dimension (2D) perovskite layer on the perovskite surface through solution post-treatment to form 2D/3D heterojunction structure,” Tan said. “However, the 2D perovskite obtained by solution post-treatment has poor uniformity (layer n value is difficult to control) and low conductivity, which is not conducive to the interface transport and extraction of carriers.”

To solve these challenges, Tan's team designed a novel 3D/3D double-layer perovskite heterostructure. Using a mixture of vacuum evaporation and solution processing, a 3D pure lead wide-bandgap perovskite film was grown on a Pb-Sn mixed narrow bandgap perovskite film.

“The 3D pure lead wide-bandgap perovskite forms a Type-II heterojunction structure with narrow bandgap perovskite, which promotes the withdrawal of charge carriers from the perovskite absorption layer to the electron transport layer, reduces the interface recombination loss between perovskite/C60, and significantly improves the open circuit voltage, fill factor and efficiency of the solar cells,” Tan explained.

The solar cell achieved a power conversion efficiency of 28.5%, an open-circuit voltage of 2.112 V, a short-circuit current of 6.5 mA cm-2, and a fill factor of 81.9%, with the Japan Electrical Safety and Environment Technology Laboratories certifying a stabilized efficiency of 28.0%. “The encapsulated tandem devices retain over 90% of their initial performance after 600 hours of continuous operation under simulated one-sun illumination,” the researchers stated.

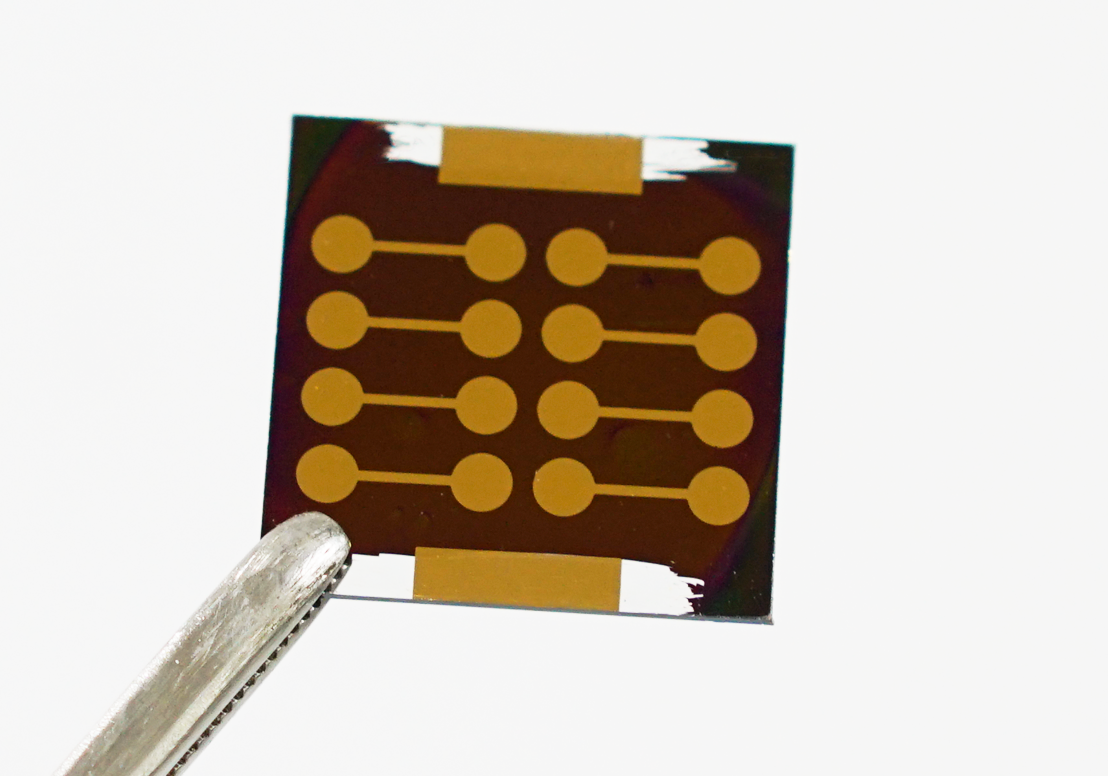

The Chinese team also fabricated a cell with a large area of 1.05 cm2, and its efficiency reached 26.9%.

The academics described the device in the study “All-perovskite tandem solar cells with 3D/3D bilayer perovskite heterojunction,” published in Nature. Looking forward, they said some electrical and optical losses should be further investigated to leverage the full potential of all-perovskite tandem solar cells. “Potential methods to address the optical loss include reducing optical reflection via light management, using more transparent front electrodes and hole transport material, and exploring thicker narrow-bandgap perovskite absorber layers,” they concluded.

Other researchers at the Nanjing University recently developed an all-perovskite tandem solar cell with an efficiency of 24.2%.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.