Scientists from the Chinese Academy of Sciences (CAS) have successfully developed a five-junction (5J) solar cell using an inverted metamorphic (IMM) design. The cell incorporates subcells made of aluminum gallium indium phosphide (AlGaInP), aluminum gallium arsenide (AlGaAs), gallium arsenide (GaAs), and indium gallium arsenide (InGaAs).

Junhua Long, the corresponding author of the research, expressed optimism about the commercial viability of the cell's configuration. “We haven't estimated the cell costs yet, but its configuration may be suitable for commercial production,” he told pv magazine.

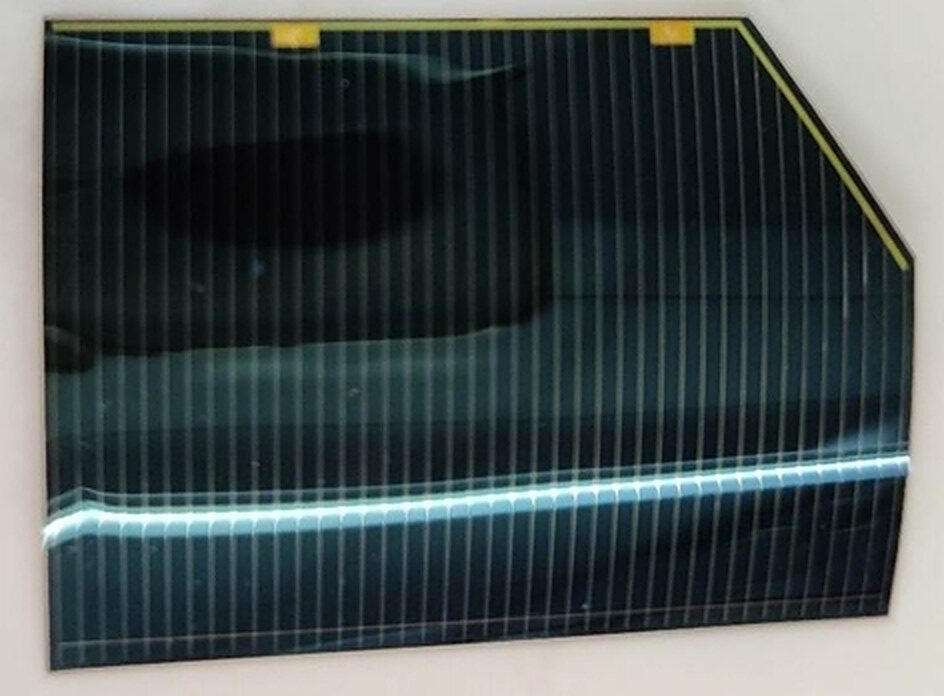

Utilizing metal-organic chemical vapor deposition (MOCVD), the researchers fabricated a 12 cm2 device featuring an AlGaInP-AlGaAs-GaAs-InGaAs-InGaAs structure. Each subcell possesses a specific bandgap energy, with values of 2.0 eV, 1.67 eV, 1.42 eV, 1.18 eV, and 0.83 eV, respectively.

The scientists highlighted the cell's surface root-mean-square roughness of 13.5 nm, explaining its significance in reducing dislocation slip obstacles and minimizing defect density in the active region.

“So the lower the epilayer surface roughness, the better the quality of mismatch growth epilayer,” they saud.

To address stress-related issues, the Chinese researchers employed low-temperature bonding techniques, effectively reducing stress-induced defects on the epitaxial materials. Furthermore, they applied an anti-reflecting coating (ARC) composed of titanium oxide and aluminum oxide (TiOx/Al2O3) using electron beam evaporation.

The 5J solar cell, evaluated under standard illumination conditions, achieved notable performance metrics. It recorded a power conversion efficiency of 35.1%, an open-circuit voltage of 4.727 V, a short-circuit current density of 860 mA/m2, and a fill factor of 86.38%.

The scientists attributed the exceptional performance of the large-size 5J solar cell to the low number of mismatch dislocations in the material and the simplicity of the flexible device's fabrication process.

They introduced the solar cell in “The fabrication of flexible and large-size inverted metamorphic five-junction solar cells,” which was recently published in Progress in Photovoltaics. The team includes academics from the University of Science and Technology of China and Chinese company Tianjin San'an Optoelectronics.

“The successful fabrication of the large-size flexible 5J IMM solar cells not only promotes the further improvement of the photoelectric conversion efficiency of multi-junction solar cells but also can further expand the possible application,” they concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.