Bioenergy is regarded by some people as one of the key options to mitigate greenhouse gas (GHG) emissions and a substitute for fossil fuels. This notion is wrong. Solar PV, wind, and other renewable energy technologies are available for large-scale electricity production with low or no direct GHG emissions. The transport sector, which is responsible for 23% of GHG emissions, is almost entirely based on fossil fuels, and has fewer alternatives.

Transportation represents some 27% of the world’s secondary energy consumption (21% of primary), grows by 1% per year on average, and is almost exclusively fueled by petroleum. Could biofuels play an important role in addressing both the GHG emissions of transport and the dependency on petroleum?

Currently marketed, first-generation biofuels represent only around 3% of global road transport fuels and therefore cannot be regarded as a transition technology. This limited penetration of first-generation biofuels is due in part to the potential competition with food crops and market prices (sugar versus ethanol prices in international markets).

Concerns that these technologies are falling short of expectations have led to the development of second-generation (cellulosic ethanol, biomass-to-liquids, pyrolysis oil, dimethyl ether) and third-generation biofuel technologies (algal-biodiesel, biofuels from third-generation processes), which still need to be scaled up in order to become cost-competitive.

With the exception of sugarcane ethanol, traditional biofuels have severe disadvantages that are related to the feedstock. The current costs of rapeseed biodiesel and ethanol from cereals or beets are much higher than the costs of gasoline and diesel, and substantial subsidies are needed to make them competitive. These high costs are a result of the low net energy yield of most annual crops (100–200 GJ/ha per year in the long term), the high-quality agricultural land required, and the intensive management requirements. For comparison, typical insolation is 50,000 GJ/ha per year and typical solar PV panel electrical output is 10,000 GJ/ha per year. The very low energy productivity per hectare of biofuels, coupled with their high requirements for fertilizers, pesticides, and water, severely limits the well-to-wheel reduction of fossil energy use, which in turn limits the environmental benefits. The net energy of perennial crops (220–550 GJ/ha per year), grasses (220–260 GJ/ha per year), and sugar cane (500–650 GJ/ha per year) is somewhat higher (but still miserable compared with solar PV).

Brazil has been a world leader in promoting biofuels for over 30 years under its Proalcool program. Mandates for large-scale blending of biofuels into vehicle fuels have appeared in several other countries in recent years, nationally driven by greenhouse gas (GHG) reduction targets, but probably also reflecting the desire of agricultural companies for production subsidies.

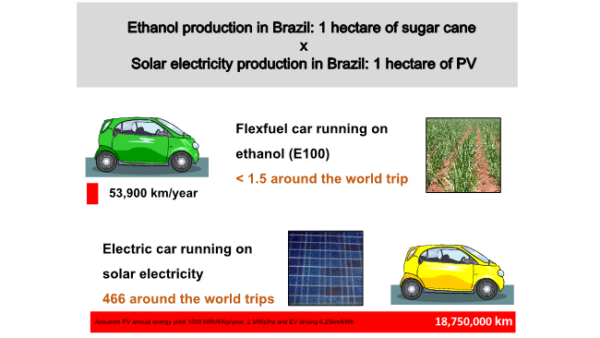

In the long term, however, it can be argued that biofuels will play a transitional role toward electric vehicles, decarbonization, and solar electricity generation. In terms of energy conversion efficiency, biofuels for transportation can be largely disregarded as a transition technology. A direct comparison between sugar cane ethanol coupled with flex-fuel cars, and sunlight-to-electricity (PV) conversion + electric cars is illustrated in the following figure.

A 1 ha (100 m x 100 m) sugar cane plantation will yield from 7,000-8,000 L of ethanol per year, allowing a medium size flex-fuel car to drive about 54,000 km/year in a best-case scenario. If the same area is covered with a dense array of low-tilt commercially available solar PV modules at 20% conversion efficiency and a moderate 1,500 kWh/kWp per year energy yield, the electricity produced over 1 year on the same 1 ha will allow the electric version of the same medium-size car to drive over 18 million km/year (about 350 times more!). The reasons for this overwhelming difference are the fact that solar PV conversion is 50-100 times more efficient than typical photosynthesis efficiency, and also the fact that the efficiency of electric motors is about three times more than internal combustion engines.

Global battery electric vehicle sales (excluding hybrids) are about 10% of light vehicle sales and growing by about 50% per year. This points to the likelihood that half of vehicle sales will be battery-electric by 2026, and that most vehicles on the road will be battery electric by 2040 as the current fossil-fueled fleet grows old and retires. Vehicles fueled by biofuels and hydrogen have a negligible market share.

In the low-moderate latitude countries of the sunbelt, where 80% of the global population lives, rooftop PV can supply most of the electricity needs of dwellings on an annual basis. Rooftop PV can also cover the additional electricity needs represented by a new fleet of electric vehicles. A kilowatt-rated rooftop PV system can drive an electric vehicle about 8,000 km per year.

Biofuels suffer from irredeemably low conversion of solar energy into useful energy, as well as competing with food production for land, water, pesticides, and fertilizers. Basic physics and economics doom the notion that bioenergy can play a significant role in global energy systems.

Authors: Prof. Andrew Blakers (ANU) and Prof. Ricardo Rüther (UFSC)

Andrew.blakers@anu.edu.au and rruther@gmail.com

ISES, the International Solar Energy Society is a UN-accredited membership NGO that was founded in 1954. It is working toward a world with 100% renewable energy for all, used efficiently and wisely.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.