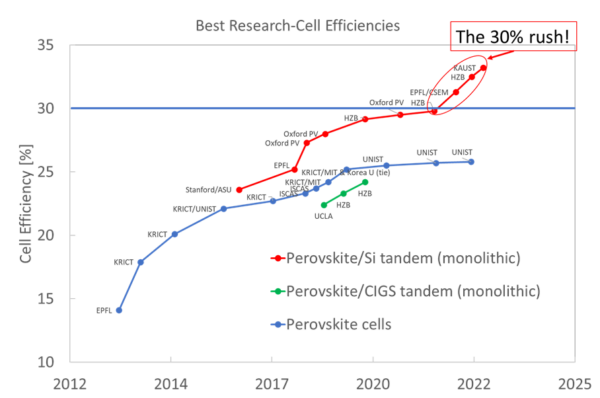

2022! What an amazing year! It was the year the PV industry reached one terawatt (TW) of global cumulative PV installations, and that the first tandem solar cell reached over 30% conversion efficiency combining silicon and perovskite materials.

Many called this 30% the psychological barrier of the technology: sort of an initiation for perovskite as an emerging technology.

Perovskite is a new material structure that quickly conquered the PV world – a world that is often very reluctant to be “impressed” by breakthrough innovations. However, perovskite solar cells, due to their processing simplicity and unique properties, have been massively studied in academic and commercial labs. Not just a few, but thousands of researchers worldwide started to improve knowledge and achieve new efficiency records with this new material. Only ten years since its introduction in PV, a lab record of 25% was achieved with a single material (single junction) device. Surpassing the efficiency limit of any single material device (name it: silicon, perovskite, CIGS, etc.) while maintaining the low-cost potential is the main gap that the PV community wants to fill. This is, so far, only possible if, instead of one single material, two materials are used for the conversion of light into electricity. Silicon and perovskite are the main candidates. Silicon is the current TW-scale material for the energy transition and perovskite because of its tunable material properties and its potential for low-cost. The combination offers the potential to reach over 30% efficiency in a low-cost, large-deployment scenario. With these two materials available, the community witnessed a rush to smash the 30% efficiency limit: “the 30% rush”!

In 2022, not once but multiple times, the 30% barrier was smashed by combining these materials. First, by Swiss researchers at CSEM/EPFL, then by TNO, TU-Eindhoven, imec and TU-Delft partners in Solliance, and finally by Helmholtz-Zentrum Berlin, which demonstrated over 32% conversion efficiency with their tandem cell. Just last April the limit has been pushed forward to 33.2% by the researchers at KAUST.

The PV community was not new to passing 30% of course, look for example at III-V semiconductors, mainly developed for space applications, but it is the first time that this efficiency has been achieved with materials with low-cost potential like the combination of silicon with perovskite.

Previous PV rushes

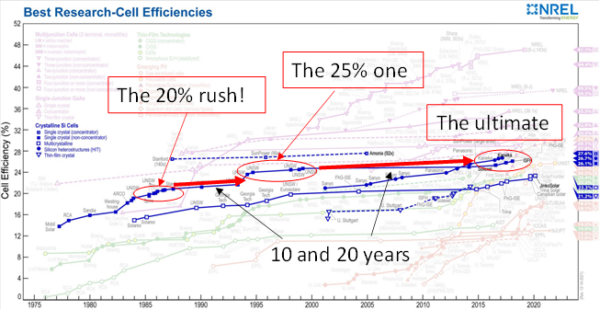

Was this the first “rush” in the PV community? Absolutely not. Looking at the world champion efficiency chart by NREL, it is clear that there were also similar patterns around 20% and 25% efficiency milestones. How do you recognize these periods? Notice the increase in cell record efficiencies just before the milestone is reached.

In recent years, we are seeing the “ultimate” rush. This is the goal to reach the highest efficiency for a single material silicon solar cell, capped at the theoretical limit of about 29%. The aim here would be to obtain the ultimate and highest record. The latest efficiency record is held by Longi at 26.8% and many companies have intentions to beat this soon.

Life after the “rush”

Historically, after a major record is reached, there is a period where development seems to slow. After the 20% rush, there was a 10-year period where no new record was achieved. Similarly, there was a 20-year gap after the 25% threshold was achieved.

So, what happens in the PV community in between each major record? To understand it, one needs to look not only at the lab record efficiency chart, but at manufacturing and installation trends. Most of these records are achieved on small areas, in research settings. The next step involves scaling to large areas through innovations to simplify processing and manufacturability, and ultimately to bring it to mass production. This requires the efforts of academia, research institutes and companies. Just to offer an example, about 12-15 years ago, researchers were focusing on developing a new n-type silicon-based cell concept. Then, the rule of thumb was that a new cell architecture was not even considered until its efficiency was above 20% on a 6-inch wafer area (at that time, the lab record was at 25%). This rule was to demonstrate the importance of large-area rather than “just” lab efficiency. After a period of rush, research focuses on narrowing the gap between the lab record and mass-produced cell efficiencies.

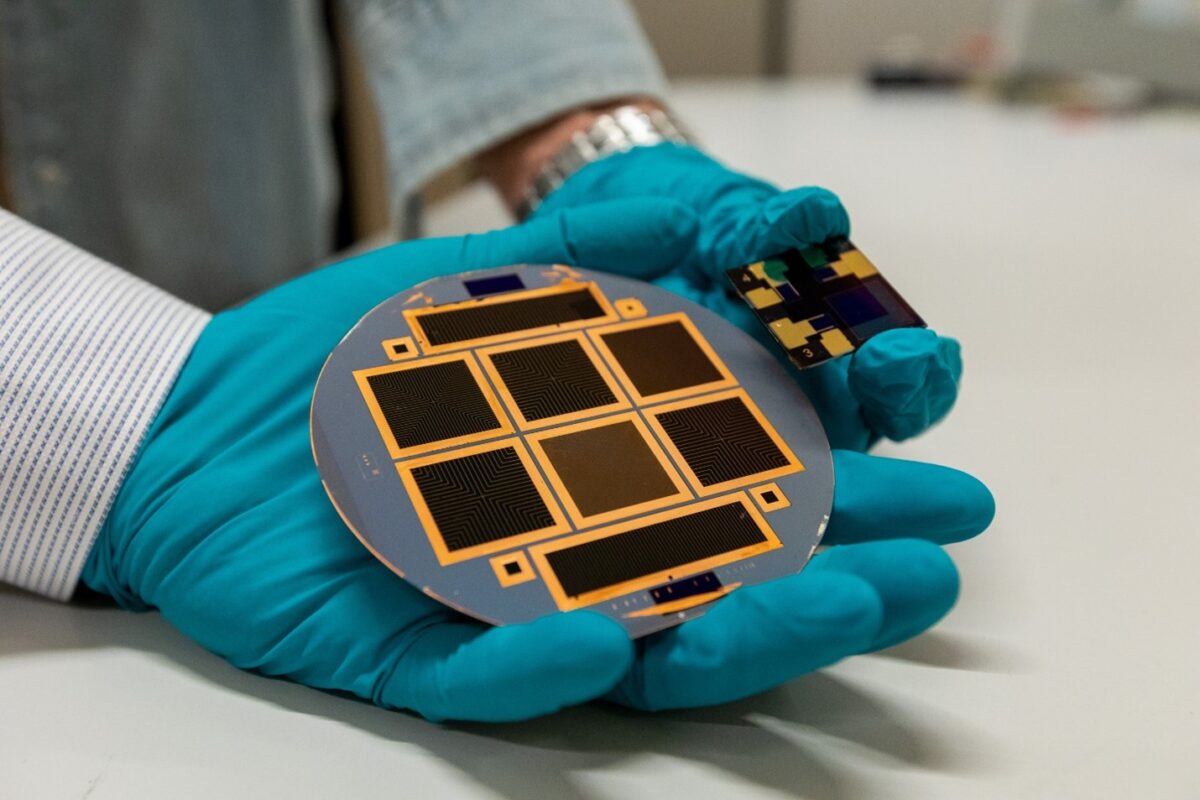

If history repeats itself, starting already this year, major resources will be focused on the industrialization of perovskite/silicon tandem cells and modules. There are four major challenges to realizing commercial tandems. First, based on the record technology, the highest-performing material stack needs to be scaled up to industry-relevant sizes (over 100s cm2). Second, the reliability of such a large-area device must be proven in relevant outdoor conditions. Third, all potential technologies need a detailed techno-economic analysis of the cost/benefit and manufacturing feasibility and (hopefully) a full lifecycle analysis. This includes material availability and new tools for the deposition of perovskite and transport layers. Lastly, large-scale manufacturing – with high-throughput tools and abundant materials – of a reliable, cost-effective, fully integrated tandem cell and module needs to be demonstrated for the technology to be bankable. Only then would the 30% rush have completed the cycle.

Of course, for the scientific community, after a new major record there’s always another threshold. And for tandem devices, we are experiencing a much faster turnover of efficiency records typical of the early stage of development of a new technology holding an incredible potential. How long do you think it will take for the PV community to reach 35%?

Gianluca Coletti is Adjunct Professor at University of New South Wales Sydney and Program Manager Tandem Photovoltaic Technology and Applications at the Netherlands Organisation for Applied Scientific Research (TNO), which is currently seeking to bring to the market a two-terminal (2T) perovskite-silicon tandem solar cell technology in the frame of a four-year research project called FIT4Market.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.