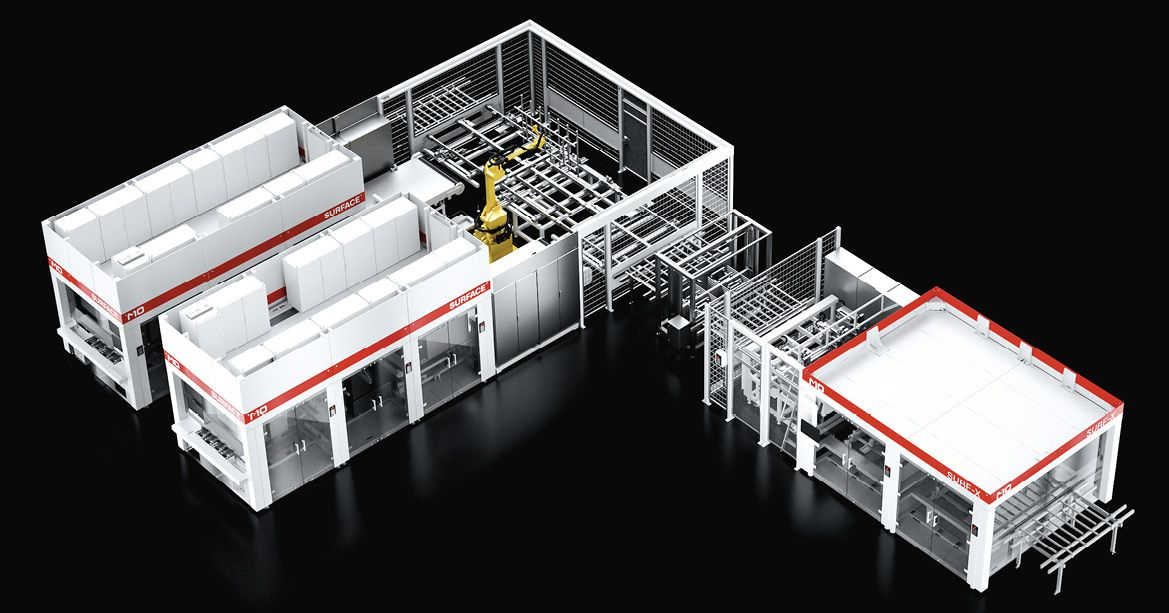

In late 2021, M10 Industries, a German manufacturing equipment supplier, and the Fraunhofer Institute for Solar Energy Systems, a research body, first published details of their shingled cell matrix technology. After a development period of just seven months, the two partners were able to demonstrate a manufacturing tool ready for series production, which they have named Surface.

This resulted in the 2021 foundation of M10 Solar Equipment GmbH, a joint venture set up by M10 Industries and Zahoransky, an automation equipment supplier, to begin producing Surface machines for large-scale, commercial PV cell interconnection, at the JV’s facility in Freiburg, Germany.

The potential is tremendous. The stringer system is the world’s first – and thus far, only – series-produced wiring machine for shingle matrix solar modules that lays and connects the shingled cells in an offset pattern across the entire surface of a module, similar to the way bricks are laid out in a wall. The conventional method of connecting cells – in which they are aligned vertically and connected as a string – is replaced by a method where cell strips are laid across the surface and connected so they overlap while being offset vertically. Electrons flow over the entire surface of the resulting module matrix, in series and in parallel.

On building facades in particular, the shingled cell matrix approach shows its strength. The technology produces aesthetically appealing modules with no gaps between cells and also offers strong shading tolerance to boost performance. Since introducing the production machine – able to process 12,000 cell strips of any size per hour – at last year’s Intersolar Europe trade show, M10 Solar has drawn interest from a range of PV manufacturers. A factory is in service at the M10 site to support potential customers with development and production of prototype modules.

Simulating the matrix

During the machine’s development phase, the responsible parties were asking themselves whether it would be able to process 12,000 cell strips per hour in operation and, if so, whether that would be the limit. What degrees of staggering and scaling would be realistic, asked the partners.

Philipp Zahn and Marco Saladin were especially interested in the answers. As joint managing directors, the pair are responsible for the fate of the M10 Solar Equipment venture. A specialist in mechanical engineering and automation, the Zahoransky business had been working with Siemens for many years and the technology companies collaborated again on the Surface innovation process.

“We’d already initiated simulations about 10 years ago, which is very unusual for a medium-sized enterprise,” says Saladin, who previously worked for Zahoransky. Instead of wasting years on table calculations or trial-and-error loops, the business relied on simulation programs for the machine concepts early on.

The managers opted for Siemens’ Tecnomatix Plant Simulation software, which Zahoransky already had experience with. The software simulates complex production systems and processes in easy-to-understand computer models and is used to simulate, visualize, analyze, and optimize production and logistics processes.

“We were able to make fast and reliable decisions and evaluate different scenarios at an early point in the Surface development phase,” Saladin says. “Plant simulation helped us design the layout, control logic, and resource dimensioning.” Saladin and Zahn believe they have achieved time savings of around 30% over the entire course of the project, thanks to the simulations.

“With plant simulation, we could quickly find the best design for our interconnection system and also achieve maximum throughput,” says Zahn. This both shortened the initial phase of production and eliminated time-consuming and costly corrective measures later in the production process.

European industry

With its innovative Surface tool, M10 is thinking far outside the box for PV module production and is looking to play a key role in bringing large scale PV manufacturing back to Europe. “If we want to make a substantial contribution to the energy transition in Europe, we have to revive PV production here at home,” says Saladin. “Our research expertise, product innovations, and historically strong mechanical engineering can be a huge help.”

Matter of time

“It’s ultimately a matter of upscaling while reconstructing entire value chains – despite difficulties in the supply chains, despite price increases, and despite geopolitical uncertainties,” says Zahn. Germany, and indeed the rest of Europe and the world, currently relies heavily on China for the supply of solar cells, modules, and related components. “In Europe, our strength is in innovative production concepts. We need to upscale them,” Saladin says. This means gigawatt-scale factories. “On this scale, simulations are indispensable,” he adds. “They become the most important tool for enabling a fast start at a realistic cost.”

pv magazine print edition

Plant simulation is often used in complete-line concepts to optimize throughput, eliminate bottlenecks, and minimize inventory. To analyze the effects of different production versions, the simulation models take into account in-house and external supply chains, production resources, and business processes. At the same time, they can evaluate different line control strategies and synchronize main and auxiliary lines. Plant simulation can define complex material-flow rules and monitor the line’s performance.

Simulation to performance

Besides Tecnomatix, Siemens offers a complete portfolio of solutions for the entire value chain – from polysilicon production and ingot cutting to cell production and module manufacturing. The integrated solutions for solar panel manufacturers and plant and machine builders include everything from power supply to plant-wide automation.

The goal is always the efficient, flexible, and sustainable production of top-quality solar panels. The M10 stringer system is the first step, and others will follow.

About the author: Tobias Wachtmann has been head of the global glass and solar business at Siemens in Karlsruhe, Germany, since June 2020. The 47-year-old began his career with the company in 2000. After training in industrial technology, he occupied Siemens sales roles before transferring to the process industries headquarters in Karlsruhe in 2012. Since 2017, he has worked in vertical glass and solar, specializing in account development.

About the author: Tobias Wachtmann has been head of the global glass and solar business at Siemens in Karlsruhe, Germany, since June 2020. The 47-year-old began his career with the company in 2000. After training in industrial technology, he occupied Siemens sales roles before transferring to the process industries headquarters in Karlsruhe in 2012. Since 2017, he has worked in vertical glass and solar, specializing in account development.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.