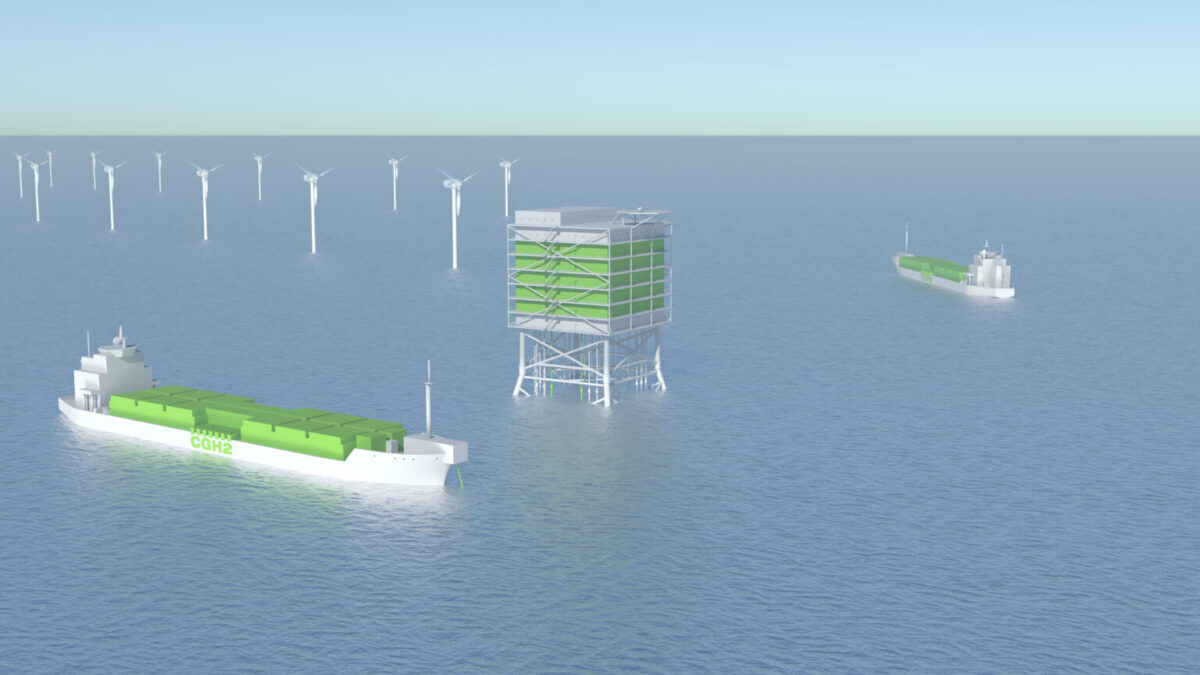

Scientists from the Fraunhofer Institute for Solar Energy Systems ISE have developed a technical concept and design for a hydrogen generation plant optimized for use at sea. The “OffsH2ore” project aims to define a technically and economically optimized design for an integrated offshore hydrogen production plant using proton exchange membrane (PEM) electrolysis, including the transport of the compressed hydrogen gas to land.

The power supply for the electrolysis comes from an offshore wind farm directly connected to a 500 MW electrolysis platform. The platform can produce up to 50,000 tons of green hydrogen per year. Fresh water for the PEM electrolyser is obtained by desalinating seawater using residual heat from electrolysis.

The produced hydrogen is purified and dried, compressed to 500 bar, and transferred to a transport vessel that can carry up to 400 tons of hydrogen from the platform to the mainland. This concept is independent of the hydrogen transport pipeline and offers flexibility in the choice of location.

“The results show that the production of hydrogen directly in the sea with a PEM electrolyzer is technically and economically feasible,” explained the scientists.

The project was funded by the German Federal Ministry for Economic Affairs and Climate Protection.

“With the concept presented by the consortium, rapid and large-scale implementation is realistic,” said the researchers.

The concept guarantees the production of hydrogen without territorial competition.

“Offshore hydrogen production offers the opportunity to cover the entire value chain at the national level while decoupling the expansion of offshore wind energy and the expansion of the grid,” said Marius Holst, the project coordinator.

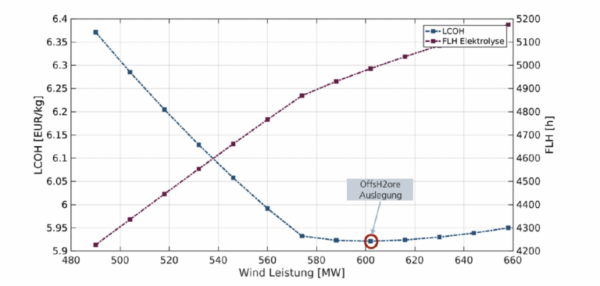

To determine the costs of hydrogen production, the first step was to determine the cost-optimal capacity of the offshore wind farm based on the electrolysis capacity of 500 MW. The minimum hydrogen production costs result from a wind power of 602 MW. In this case, they amount to 5.92 EUR/kg with just under 5,000 full charge hours of electrolysis.

Hydrogen production costs increase and full charge hours decrease with lower wind capacity. For example, a wind farm with a capacity of 490 MW results in hydrogen production costs of €6.37 ($7.04)/kg and full load hours of around 4,225 h/a. As a result of the lower wind capacity, the 500 MW electrolysis is significantly oversized and can no longer operate at a nominal load.

The consortium that worked on the project included Fraunhofer ISE, PNE AG as project coordinator, SILICA Verfahrenstechnik GmbH, KONGSTEIN GmbH, and Wystrach GmbH.

Scientists from Australia's University of Adelaide recently discovered a way to produce hydrogen directly from untreated seawater. For this, they introduced an acid layer on the catalysts in situ.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.