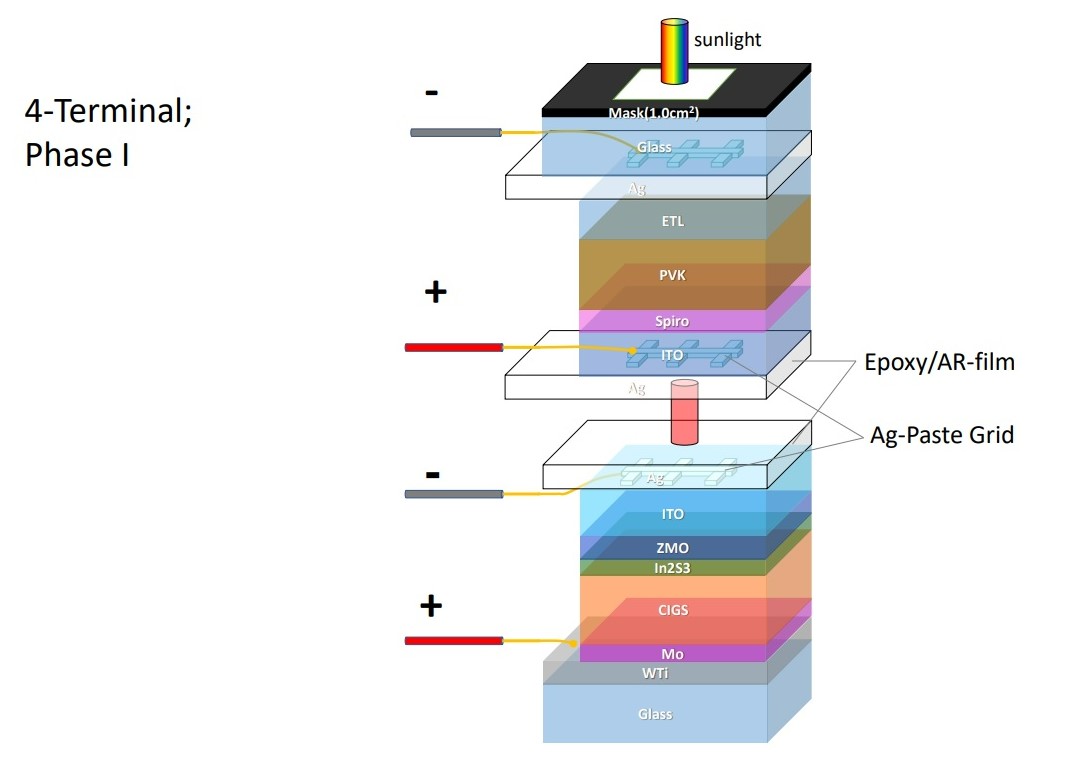

UCLA researchers and Midsummer, a Swedish building-integrated PV (BIPV) module manufacturer, claim to have demonstrated a four-terminal (4T) tandem solar cell. It is based on a top cell made of perovskite and a bottom cell relying on copper, indium, gallium and selenium (CIGS).

“The cell is based on a perovskite top cell that has been optimized for integration with Midsummer’s CIGS cells that are utilized in their commercial suite of BIPV products,” said Midsummer, without revealing any additional technical details. “The research continues with the aim of a two-terminal perovskite-CIGS cell which will render this particular solar cell highly competitive and suitable for mass production.”

The manufacturer said the tandem cell is suitable for its Duo production equipment, which manufactures 56 mm x 156 mm CIGS cells on a flexible stainless steel substrate.

UCLA set an initial efficiency record for such tandem cells in 2018, at 22.4%. This surpassed the 17.8% efficiency achieved in 2016 by a collaboration of European research institutes, which developed a peroskite/CIGS mini-module measuring 3.76cm².

The US researchers designed the bottom cell as having an indium zinc oxide (IZO) transparent conductive oxide film, a tin(IV) oxide (SnO2) buffer layer, a perovskite layer, and a layer of methyl-substituted carbazole (Me-4PACz) as the hole-transport layer. For the top cell, they used an indium tin oxide (ITO) substrate, a cadmium sulfide (Cds) layer, and a CIGS absorber.

Yang Yang, a UCLA professor of materials science, said at the time that devices with similar designs could reach efficiencies above 30%.

“We feel fortunate to be working with Professor Yang’s group at UCLA which has demonstrated key advances in perovskites,” said Leon Chiu, president of Pioneer Materials, which is a key supplier for compound sputtering targets used in Midsummer’s novel processing for CIGS on stainless steel. “Integrating Midsummer’s production proven CIGS processing with Yang’s Lab tailored perovskite shows a clear path toward expanding the reach of BIPV by improving efficiency and lowering costs.”

Midsummer currently operates a 50 MW manufacturing facility in Bari, southern Italy, and another factory in Sweden. In 2020, it released a 500 W solar panel for large rooftop arrays.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.