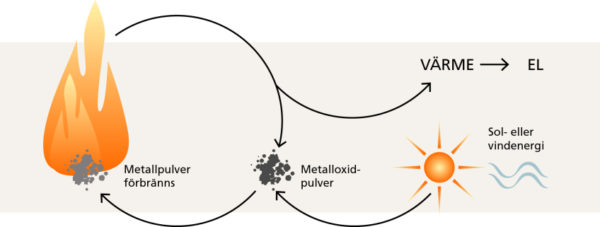

Researchers at Lund University in Sweden have developed a way to store electricity produced by wind and solar installations, by incinerating scrap metals. The storage technique uses wind and solar electricity to power systems that combust metal power, usually iron or aluminum, and make it react with heated air or steam.

“The heat released can be used to drive turbines which in turn produce electricity,” the scientists said, noting that at the end of this process, the metal oxide remains as a powder. “Alternatively, one can choose to produce hydrogen gas, in which case the combustion takes place with hot steam.”

They said that by using solar or wind power, the oxidized powder can become ordinary metal again. The claimed that the process is safe, cheap and fossil-free.

“Using electrolysis, the metal oxide can be converted back into metal,” said the researchers. “It can be done by pouring the metal oxide powder into a solution with cryolite into which two current-carrying electrodes are inserted to start a chemical reaction.”

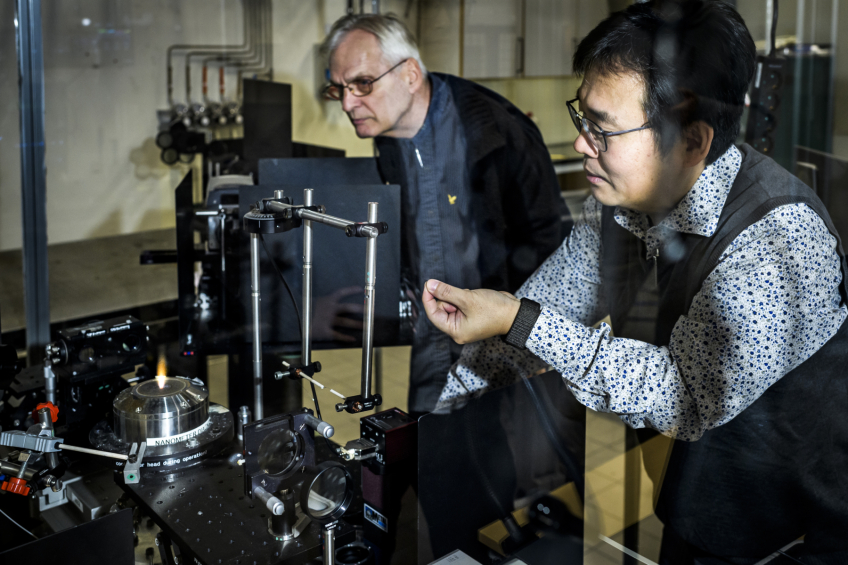

The research group plans to build a facility based on the circular process at a brewery in southern Sweden, where electricity production needs to be expanded. Their work builds on multi-year research efforts on the burning of metals such as iron and aluminum.

“The pilot plant will be like a small coal-fired power plant, but where the coal is replaced by iron,” said researcher Marcus Aldén.

The team hopes to replicate the plan at other locations in Sweden's Skåne region.

“Together with some research groups in Germany, Canada and Holland, we came to the conclusion that these common metals are so promising as both an energy source and an energy carrier that they could function as an element of the energy supply,” the academics said, without providing additional technical details.

The researchers are likely referring to the Max-Planck-Institut für Eisenforschung in Germany and TU Eindhoven in the Netherlands, which published a paper in Acta Materialia in October to present a similar technology.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

A better route for storing RE would be something like the Calcium Oxide to Calcium Hydroxide reaction. This reaction can achieve temperatures in the 500 to 600 C range which is high enough to provide process heat to a wide variety of industries. It’s also hot enough for an efficient steam cycle. The Calcium Hydroxide can be turned back into Calcium Oxide with the application of heat at 580 C.

Ideally you want the reversible reaction to use heat rather than electricity. This makes it so you can pair cheap thermal storage with your chemical reactor and maintain high capacity factors with your expensive equipment. It’s not as easy to do this if you use metals because you need electricity for the electrolysis step – i.e. it’s harder to maintain high capacity factors with your expensive equipment.

This innovative approach proposed by Swedish scientists to store solar power by incinerating metals like aluminum and iron shows great promise. By utilizing excess wind and solar electricity to power systems that combust metal powder, the resulting heat can be used to generate electricity or produce hydrogen gas. The process of converting metal oxide back into metal using electrolysis is a remarkable feat, making it a safe, cost-effective, and fossil-free method of energy storage. This advancement could play a crucial role in enhancing renewable energy integration and reducing reliance on traditional power sources. Kudos to the researchers for their groundbreaking work!