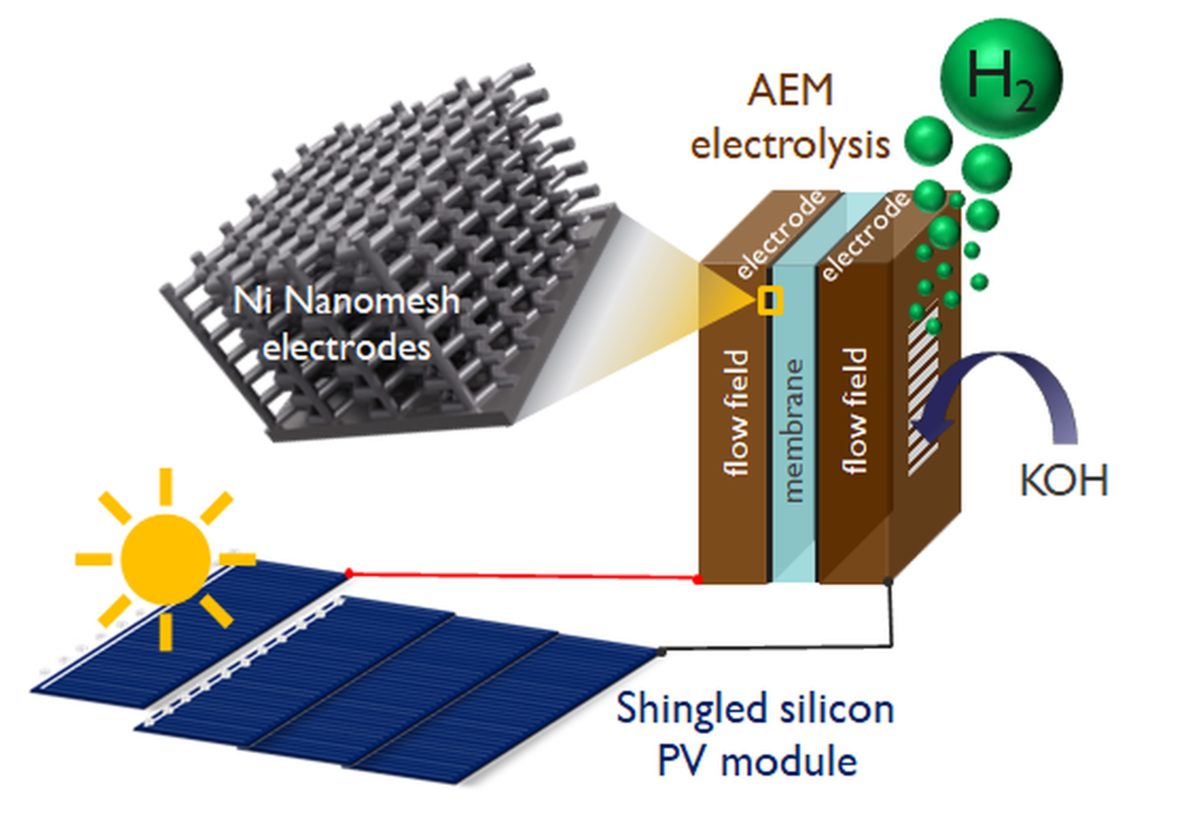

Imec researchers in Belgium have developed anion exchange membrane (AEM) water electrolysis for hydrogen generation. They said their approach can be combined with solar generation in a photovoltaic-electrolyzer (PV-EC) configuration.

“The novelty of our approach consists of utilizing standard-sized large area shingled silicon PV to provide over 1.23V for water splitting combined with low-cost anion-exchange water electrolysis, which combines the higher operating current densities of polymer electrolyte membrane (PEM) with low-cost materials from the alkaline electrolysis,” researcher Nina Plankensteiner told pv magazine.

The scientists presented their findings in “Photovoltaic–Electrolyzer System Operated at >50 mA cm−2 by Combining Large-Area Shingled Silicon Photovoltaic Module with High Surface Area Nickel Electrodes for Low-Cost Green H2 Generation,” which was recently published in RRL Solar. They explained that PV-ECs offer the highest technological readiness level and the highest solar-to-hydrogen efficiencies among all electrolyzer technologies.

“In PV-EC systems the photovoltaic technology of choice, that commercially delivers low-cost electricity with stable efficiencies of 20-25% at 30-40mA/cm2, are in-series connected silicon solar cells, providing >1.23V for water splitting,” said researcher Joachim John. “In the next decade, silicon-tandem configurations with perovskite top-cells might play an additional role with conversion efficiencies approaching 30%.”

They described the proposed system as having a “commercially relevant configuration.” They said that the AEM electrolyzer features nanomesh electrodes with a huge surface area of 26 m2/cm3 made of earth-abundant nickel, as the researchers previously reported.

“In-series shingling of silicon solar cells is an especially attractive approach for solar water splitting applications, since a sufficient high voltage per standard cell area can be achieved,” they said, in reference to the shingled panels.

The modules are busbar-free structures, with only a small proportion of cells not exposed to sunlight. The cells are bonded to form a shingled high-density string and the resulting strips are connected through a conductive adhesive. The reduced number of busbars reduces shadowing losses.

The lab-scale, single-cell electrolyzer developed by the academics features two 4-micrometer thin high-surface area nickel nanomesh electrodes. It also features six silicon heterojunction cells with shingles of 38.5 cm2 cut from 15.6 cm2 x 15.6 cm2 standard cells.

“The cells were connected in-series and span a variable open-circuit voltage range from 0.7V to 4.3V, depending on the number of cells connected,” the scientists explained, noting that the cells achieved an average efficiency of around 20% and a fill factor of approximately 80%. “The current-voltage characteristics from the electrolyzer showed that 1.8 V to 2.2 V are required to match an electrolyzer current density between 20 and 100mA/cm2. This minimum voltage requirement can be achieved by connecting three or four silicon cells in-series.”

Tested under standard illumination conditions, the PV-EC system was reportedly able to produce hydrogen for around 20 hours and achieved a solar-to-hydrogen efficiency of 10% at electrolyzer current densities of approximately 60 mA cm−2, which the team described as the highest current density reported for PV-EC systems in the literature.

The solar-to-hydrogen efficiency was determined by in-situ monitoring of the most important system parameters, such as operating current, voltage, and hydrogen gas flow. The researchers said that the accurate determination of this figure of merit is important when comparing PV-EC systems with each other. They noted that longer stability measurements should be tested at sufficiently high current densities to stress the system.

The researchers also performed a series of performance dynamic load tests with gradual and abrupt power input changes over half a year of solar radiation. They claim that the tests showed that cell voltage changes are negligible and have a very small impact on PV-EC operation and hydrogen production.

“The next steps towards commercialization of the presented PV-EC system are long-term outdoor stability testing along with longer dynamic load measurement protocols,” they concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.