Scientists led by the University of Rochester in New York state have considerably reduced electron recombination processes in lead-halide perovskites (LHPs) used for solar cell applications. Recombination can have a significant impact on electrical performance in perovskite cells, with implications for open-circuit voltage, short-circuit current, fill factor, and ultimately, power conversion efficiency.

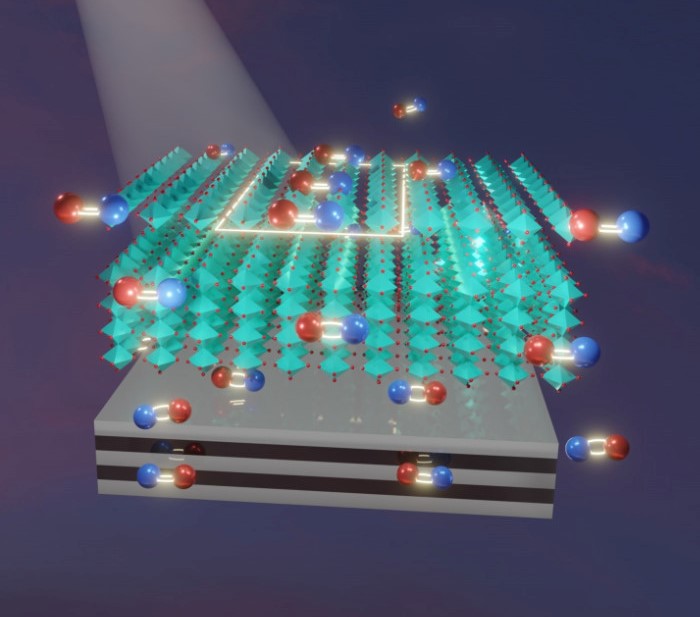

The researchers used what they call a “physics-based method” to create a film based on a type of LHP known as methylammonium lead iodide (MAPbI3). They deposited that directly on a plasmonic substrate made of hyperbolic metamaterial (HMM) with a high local density of state, via spin coating. They fabricated the multi-layered HMM with four pairs of alternative 10 nm thick layers made of silver, aluminum sulfate, and ozone (Ag-Al2 O3) by electron beam evaporation.

“The metal layer serves as a mirror, which creates reversed images of electron-hole pairs, weakening the ability of the electrons to recombine with the holes,” the scientists said, noting that they used a momentum-resolved imaging technique to characterize the film's transition dipole orientation, which is the key factor enabling control over exciton recombination processes.

They claim that the interaction between the in–plane dipole of the LHP and its image formed on plasmonic substrate results in a tenfold decrease in the recombination rate, without any chemical treatment, optical cavity, and photonic band–gap engineering.

“Furthermore, image dipole interaction enables us to substantially improve the device performance of photodetectors by achieving more than 250% increase in the photoresponsivity,” they added.

The academics presented their findings in “Gigantic suppression of recombination rate in 3D lead-halide perovskites for enhanced photodetector performance,” which was recently published in Nature Photonics.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.