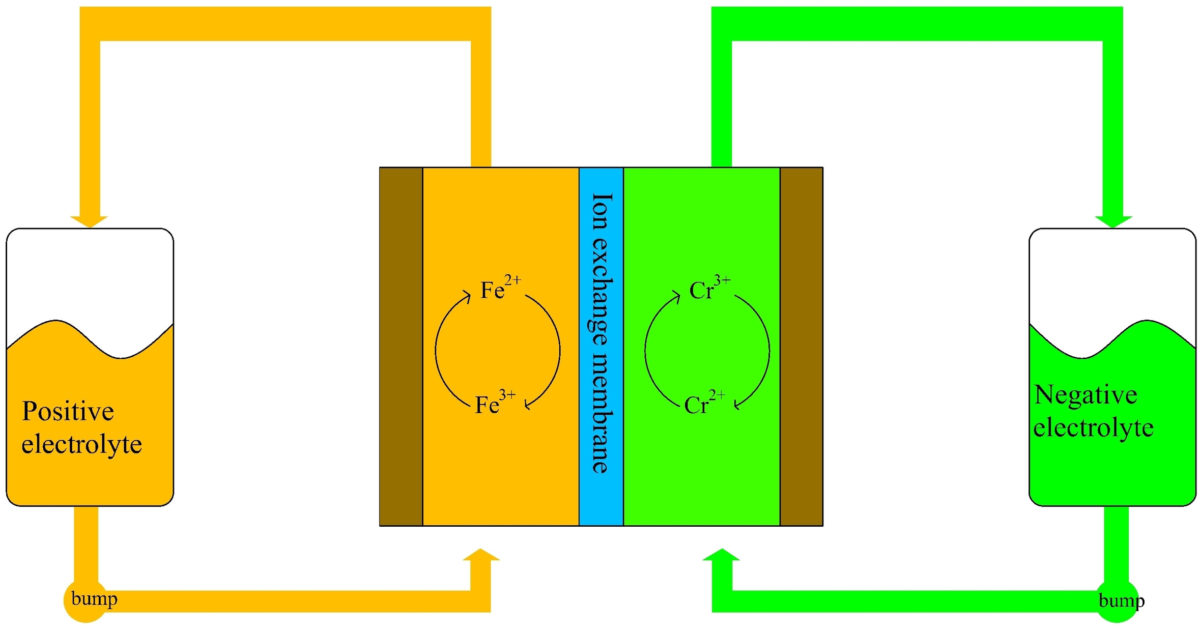

Iron-chromium redox flow batteries are a good fit for large-scale energy storage applications due to their high safety, long cycle life, cost performance, and environmental friendliness. However, their widespread adoption has been limited for reasons such as the low performance of graphite felt, which is the most commonly used electrode in iron-chromium flow batteries.

Now a group of researchers from the University of Science and Technology Liaoning and the Yingkou Institute of Technology in China have developed a method to greatly improve the performance of the electrode, consequently increasing the energy efficiency of the flow battery by even up to 1.85 times.

They prepared cobalt oxide-modified graphite felt electrodes by electrodepositing cobalt nitrate on graphite felt, which was then calcined. They then analyzed this new electrode material with field emission scanning electron microscopy (SEM) and X-ray energy dispersive spectroscopy (EDS).

The researchers also explored the influence of different concentrations of cobalt oxide on the electrochemical performance of graphite felt as a flow battery electrode.

Their results showed that the method of calcination after electrodeposition successfully attaches cobalt oxide to the graphite felt fiber uniformly in granular form. It increases a large number of oxygen-containing functional groups, and significantly improves the performance of the iron-chromium redox flow battery, as well as its charging capacity and Coulombic efficiency.

Namely, the researchers found that the charging capacity at a current density of 140 mAcm−2 can reach up to 1.85 times that of the original graphite felt. The modified sample has a maximum Coulombic efficiency of 82 % at a high current density of 250 mAcm−2.

They discussed the results in “Research on the Performance of Cobalt Oxide Decorated Graphite Felt as Electrode of Iron-Chromium Flow Battery” which was recently published in Chemistry Europe.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.