Unlike their cousins, vanadium redox flow batteries (RFBs), which suffer from intrinsic low energy density, zinc-bromine RFBs have high theoretical energy densities (440 Wh/kg). However, the poor kinetics and poor reversible behavior of Br2/Br− redox activity pose significant barriers to realizing that potential.

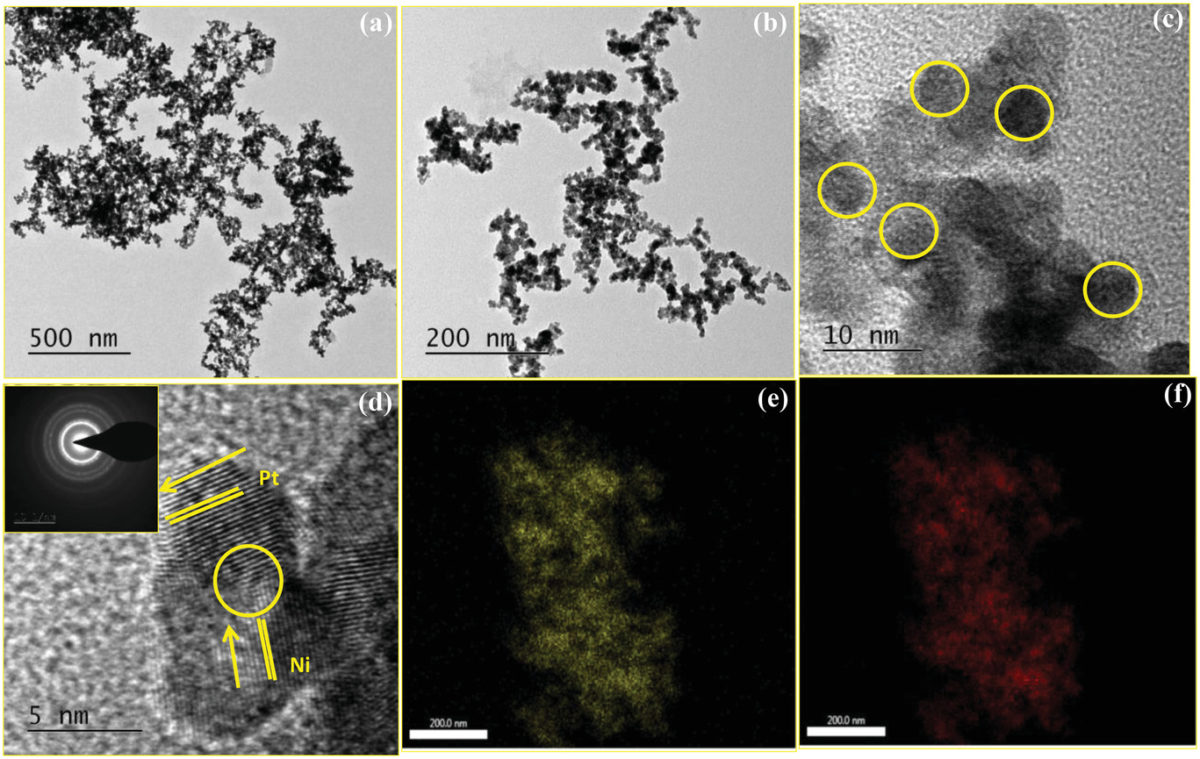

To increase the efficiency of the flow cell, researchers at the Central Electrochemical Research Institute (CECRI) in India have developed graphite felt (GF) supported platinum-nickel (PtNi) bimetallic alloy-based electrode. The 3D structure GF -based metal particles decorated electrode-based flow cells showed an impressive performance at all the tested conditions.

The Ni-rich Pt0.5Ni1@HT-GF-based flow cell accomplished a superpower density of about 1550 mW cm−2, which is greater than that of a bare GF-based flow cell at 1260 mW cm−2. The cycle life showed excellent stability up to 300 cycles with coulombic, voltage, and energy efficiency of 97%, 86%, and 83%, respectively.

According to the researchers, the improved redox kinetics parameters are due to the high electro-catalytic nature of the heat-treated Ni-rich PtNi coating deposited on the GF. In the process of testing, the sample cell was subjected to different current densities from 20 to 140 mA cm−2.

Considering the high cost of platinum, the metal’s content was kept to a minimum and the redox reaction was augmented on the back of nickel’s catalytic activity. The bimetal catalyst was deposited on the 3D GF network electrode via a chemical reduction method.

The new research is said to offer a promising approach to developing effective electrode materials for a superpower RFB system. The scientists discuss their findings in “Nanocatalyzed PtNi Alloy Intact @3D Graphite Felt as an Effective Electrode for Super Power Redox Flow Battery,” which was recently published in Advanced Materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.