Researchers at Sohag University in Egypt have developed a passive cooling system for solar panels that uses a PCM known as paraffin wax RT-42.

PCMs can absorb, store and release large amounts of latent heat over a defined temperature range and have often been used, at the research level, for PV module cooling. Paraffin wax is obtained from petroleum by dewaxing light lubricating oil stocks and is commonly used in candles, wax paper, polishes, cosmetics, and electrical insulators.

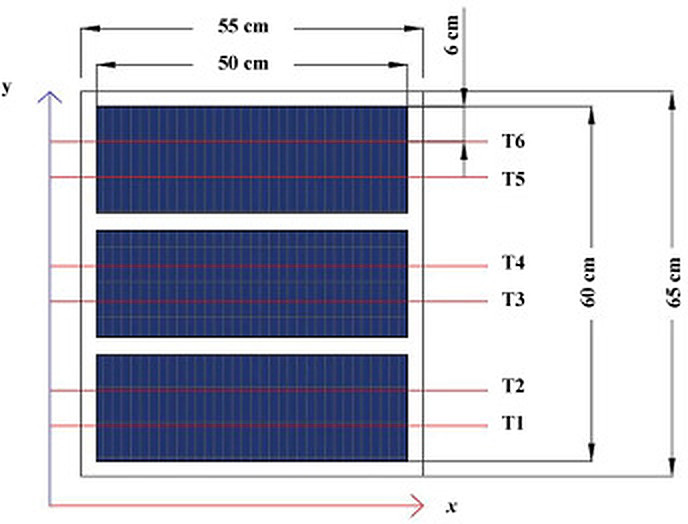

The scientists placed the cooling system on a 40 W polycrystalline panel with a size of 55 cm × 65 cm and compared its performance with that of an identical reference panel without cooling. They tested the panels with tilt angles of 15, 20, 25, and 30 degrees and with different PCM thicknesses.

The two modules have an efficiency of 16.5%, an open-circuit voltage of 12 V, a short-circuit current of 4.3 A, and a fill factor of 0.78.

“To accommodate the PV panels, a rectangular PCM container with inside dimensions of 55 cm × 65 cm x 4 cm made of a 2 mm thick galvanized sheet is used,” the group explained. “The container is mounted to the back side of the PV panel and coated with a silicon adhesion to prevent the possible leakage when the PCM is completely melted.”

The academics measured the temperature distribution on the front surface of the PV panels at different sections using an infrared camera. During the experiment, they observed that, for all thicknesses of the PCM, increasing the tilt angle of the panel reduces the surface temperature. ”

“When the PV-PCM panel is installed at an angle of 15 degrees, it records the highest temperature distribution over the panel surface, while the lowest temperature is recorded for the surface of the solar panel at a tilt angle of 30 degrees,” they stressed. “This is likely ascribed to the fact that the energy flow within the PCM due to the convection is very low when the tilt angle is small.”

The cooled panel, when installed with a tilt angle of 30 degrees, achieved a power yield that was 15.8% higher than that of the reference module without cooling.

“Changing the tilt angle from 15 degrees to 30 degrees enhances the electrical efficiency of PV-PCM with 3 cm thickness by 7.4%,” the scientists stated. “Finally, using PCM with a thickness of 3 cm increases the electrical efficiency of PV-PCM panel by 14.4% compared to the PV reference panel.”

The scientists did not provide information about the cost of the proposed technology and its applicability to commercial production. They described the passive cooling technique in “Performance enhancement of PV panels using phase change material (PCM): An experimental implementation,” which was recently published in Case Studies in Thermal Engineering.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.