Researchers led by Hebei University in China have developed a low-temperature, non-vacuum, large-area spray passivation technique to compensate for the efficiency losses caused by the cutting and separating process in the production of shingled solar panels based on TOPCon and HJT technology.

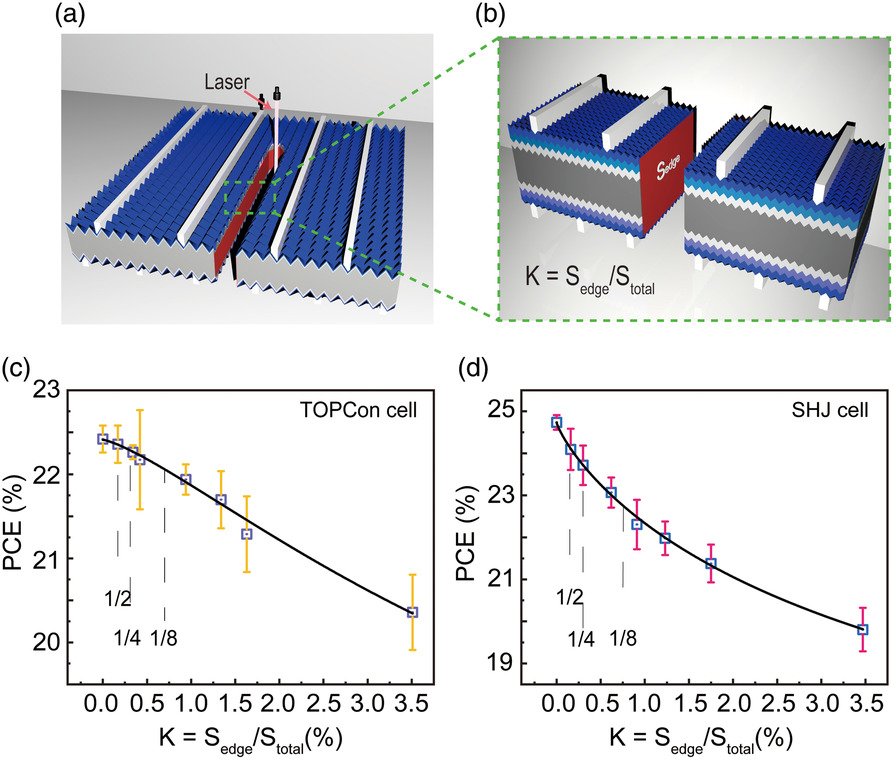

The academics explained that the losses are caused by the integration of stripes into the shingled panels in the cell-to-module (CTM) process, as the solar cells must be cut into more subcells through a laser scribing process that leaves unpassivated edge surfaces, which in turn results in efficiency declines due to recombination.

“In order to compensate this recombination loss during the CTM process, we used a organic polymer ink mixed by ethanol, water and Nafion to form the passivation layer,” the scientists said. “We show that the organic passivation coating can substantially reduce the newly formed edge loss from laser scribing.”

The said the spraying method can produce a uniform film on the passivate side compared to the unpassivated one.

“The solar cells with the passivation layer are much brighter than those without one. It indicates that the organic passivation layer has an excellent edge passivation effect for both TOPCon and SHJ solar cells and the edge recombination losses are largely reduced,” they said, adding that the passivation layer significantly increases the open-circuit voltage and fill factor of cells.

They found that the technique could increase the fill factor of a 24.4%-efficient HJT device from 77.9% to 82.5%, with the efficiency itself growing by 1% to 2%.

“The device can achieve long-term stability through the careful controlling of humidity and the simple packaging technology,” they also stated.

pv magazine print edition

The scientists introduced the new technique in “Compensating Cutting Losses by Passivation Solution for Industry Upgradation of TOPCon and SHJ Solar Cells,” which was recently published in Advanced Energy & Sustainability Research. The research group also includes scientists from Chinese module maker Yingli Green Energy Holding Co., Ltd. and the Quzhou Green Industry Clustering Zone.

“This straightforward and non-vacuum method is compatible with current production line and can be directly applied to industrial silicon solar cells in the future,” they concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.