Chemical engineers from École polytechnique fédérale de Lausanne (EPFL) have developed a solar-powered transparent, porous and conductive electrode, which uses an input stream of humid air to produce H2.

The electrode’s substrate is a three-dimensional mesh of felted glass fibers, a type of glass wool, which is essentially quartz. The silicon oxide fibers are then fused together at high temperatures to produce felt wafers. The wafers are initially coated with a transparent thin film of fluorine-doped tin oxide, and then with a thin-film of sunlight-absorbing semiconductor materials.

“The coating of various semiconductors on the substrates is established including Fe2O3 (chemical bath deposition), CuSCN and Cu2O (electrodeposition), and conjugated polymers (dip coating),” the scientists wrote in “Transparent Porous Conductive Substrates for Gas-Phase Photoelectrochemical Hydrogen Production,” which was recently published in Advanced Materials.

The scientists took inspiration for the electrode from the way in which plants can convert sunlight into chemical energy by using carbon dioxide from the air.

“Since each step is relatively simple and scalable, I think that our approach will open new horizons for a wide range of applications starting from gas diffusion substrates for solar-driven hydrogen production,” said Marina Caretti, the lead author of the project.

The scientists did not formally study the solar-to-hydrogen conversion efficiency in their demonstration, but they acknowledge that it is modest for this prototype.

“Based on the materials used, the maximum theoretical solar-to-hydrogen conversion efficiency of the coated wafer is 12%, whereas liquid cells have been demonstrated up to 19% efficient,” said the EPFL engineers. They worked in collaboration with Toyota Motor Europe.

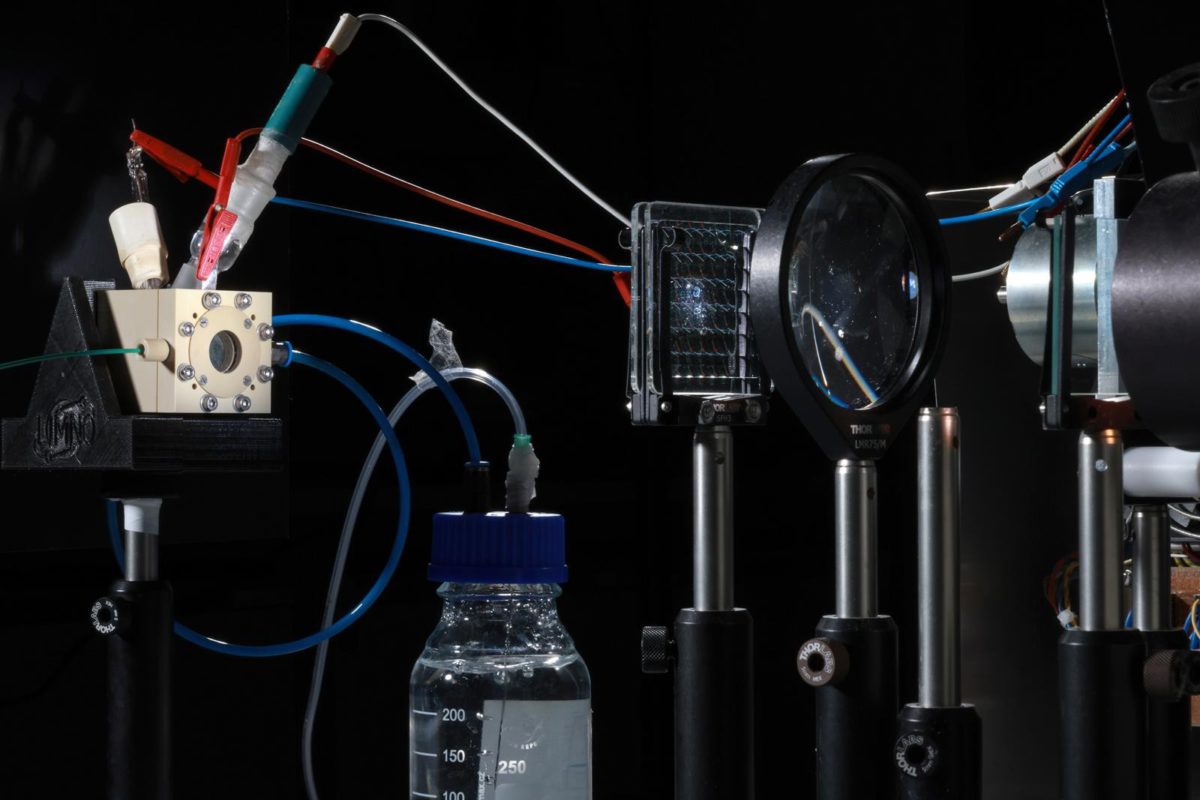

To examine the possibility of the transparent porous conducting substrate (TPCS)-based photocathode to produce H2 in a gas-phase environment, the team constructed a half-gas phase cell composed of two compartments. The anode side operated in an acidic liquid electrolyte, while the electrode was pressed into a polymer electrolyte membrane (PEM) to form a photoelectrode-membrane assembly.

They concluded that the TPCS is “a promising substrate for the further development of the PEM-PEC concept and other applications where high porosity, conductivity, and transparency are required.”

Photoelectrochemical (PEC) technology produces hydrogen from water by using sunlight and specialized semiconductors known as “photoelectrochemical materials.” The scientists will now work on a fully functional photosynthetic fuel cell using the new electrode.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.