Image: Inion Software

The global popularity of energy storage systems has been reflected in a lithium price which rose from $10,000 in the summer to $80,000 in the autumn.

The deployment of battery storage with solar in all project sizes, and the popularity of electric vehicles, is stoking demand. Consider, for example, the €1 million ($1.06 million*) budget allocated by the Lithuanian government last year for a program to help people buy residential batteries which was swallowed up on day one by almost 300 applications worth an average €4,200 each. With electricity companies increasingly turning away from paying fixed fees for excess solar energy fed into their grids by households, in favor of selling such energy on the wholesale market at rock-bottom prices, and demand for storage systems is being stoked even further.

Hybrid inverters

Inverters play an increasingly important role in residential solar-plus-storage systems. Traditional inverters converting power from a battery into the alternating current required by grids operate on factual data, such as electricity meter readings and the operation of a solar array, which can mean battery charge cycles are not conserved.

Solar households increasingly want their inverters to be a more efficient “brain” of their solar-plus-storage systems by using artificial intelligence (AI) to manage the battery storage cycles, for example by taking expected future usage patterns into account.

It is widely known that more-intelligent inverters maximize the potential of solar households to save money, including by harnessing time-of-use electricity tariffs so batteries are charged when prices are low and the energy is released when grid prices peak.

What may not be appreciated yet is just how much money-saving punch smart inverters can pack and it is worth considering a few examples to illustrate the point.

Smart inverter battery management

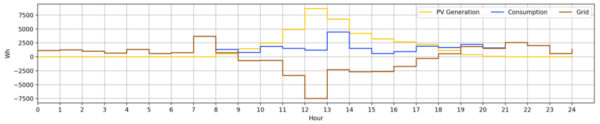

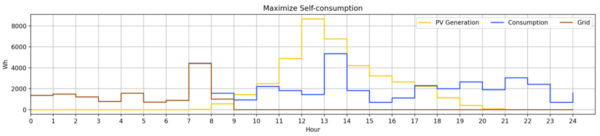

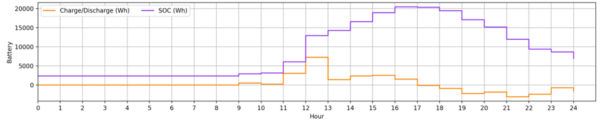

Consider a 10 kWp solar array which generates 39 kWh of solar energy daily. The system generates 19 kWh more per day than is consumed by the household. Without a battery, that excess electricity – 49% of the power produced – is exported to the grid.

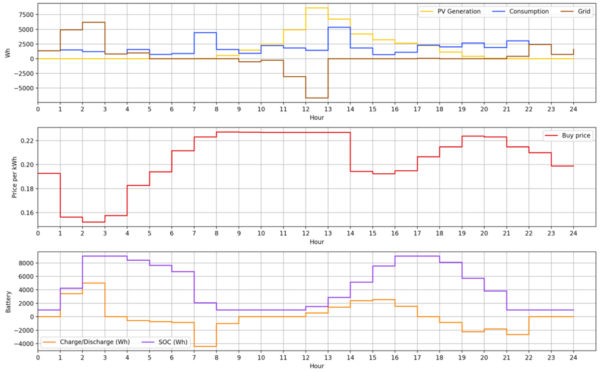

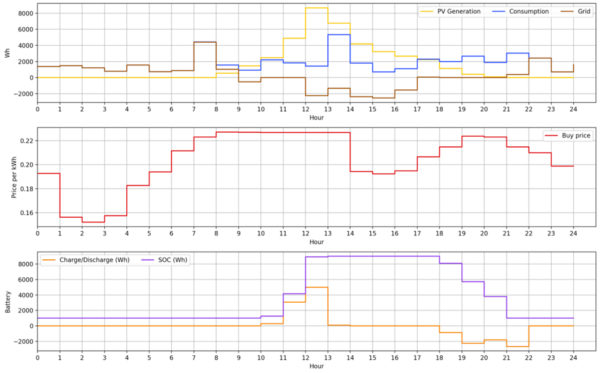

Graphics: Inion Software

In this case, a 19 kWh lithium battery would not be enough to store all the surplus energy. Lithium-ion batteries should never be fully charged or discharged. To maximize battery life, the minimum and maximum state of charge should be limited to 10% and 90%, respectively. Effective battery capacity is, therefore, 80% of the nominal figure, so a 24 kWh device is more appropriate to store 19 kWh of excess energy.

At the start of each day, the battery charge level should be 10% of nominal device capacity and excess energy will be stored throughout the day and drawn down as required, for instance each morning as energy demand rises and solar production is not sufficient. Choosing the largest battery – 24 kWh, in our example – may not be the best strategy, however, due to the high lithium, and therefore battery costs already mentioned. Plus, in autumn and winter, the solar panels will generate less power, meaning less excess energy to manage. Just as with choosing solar array size, household electricity consumption must be considered.

To illustrate the factors to take into account when sizing a battery, consider the purely theoretical scenario of a household which consumes 46 kWh daily, all of which comes from the grid. Assuming one hour per day of absolute minimum electricity price, unlimited ability to draw down electricity from the grid during that hour, and unlimited battery charging capacity, the ideal lithium battery would have a nominal capacity of 58 kWh, that could be charged during an hour and then offer the electricity to be drawn down for the rest of the day.

Remember also that lithium batteries have a limited lifetime so there is a cost to storing energy in a battery above the initial purchase price. A lithium battery life cycle is considered over once a device can only charge to 80% of its nominal capacity. Knowing a battery's capacity, price, and number of cycles, enables the calculation of the average cost of storing 1 kWh of energy. The calculation becomes more accurate if the battery's depth of discharge is known, as that affects the device's number of cycles.

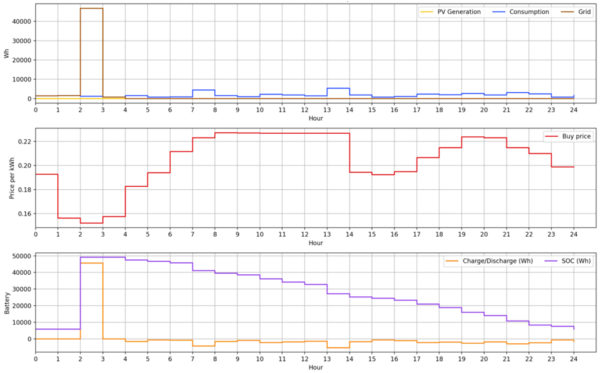

Considering another example, of a solar array with a 10 kWh lithium battery, indicates just how “smart,” inverters can be. In conventional cost-minimization mode, the battery charges between 4 a.m. and 8 a.m. daily, when the electricity price is lowest and the solar panels are not generating sufficient energy, for release during the day. A non-AI enabled inverter, however, does not include the cost of storing each kilowatt-hour of electricity, based on battery capability. If that ongoing cost of storing energy was 0.06 currency units, as in the diagram below, it would not make sense to charge the battery at that point, when the purchase price of the system is thrown in. A smart inverter, however, can take such nuances into account and switch battery management modes accordingly.

Smarten up

Research by Inion Software has indicated an ability to turn almost any inverter into a smart device. All that is required is a “logger” which gives the inverter more options for battery management. The logger should enable an inverter to manage a battery under five scenarios: cost-minimization; energy self-consumption; “peak shaving” (evening out energy consumption); electricity self-sufficiency; and curtailment of excess energy.

Our studies show numerous inverters feature parameters which can be adjusted, making it easier to connect a logger.

Not all devices are so malleable, however. We tested one inverter which gives a command to charge the battery to a certain level but then switches the storage system to self-consumption mode. A smart logger, reacting to the situation most favorable for the customer in real time, can instead switch the battery to cost-minimization mode but the inverter we tested in this case did not “listen” to the logger.

Inverter makers can address this problem by modifying their device operating program sufficiently to enable third-party companies to control the charging and discharging capacity of batteries after connection to an inverter. This would enable inverters to manage batteries intelligently and learn how customers use household electricity.

*Currency conversion correct on 30/12/2022.

About the author: Robertas Janickas is chief technology officer at Lithuanian business Inion Software. He has more than 10 years' experience in management, software, and soft- and hardware development. Inion Software is a company developing a one-stop solar plant monitoring platform and energy management system for battery management.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.