From pv magazine 12/2022.

Hail risk to solar projects is on the increase due to a perfect storm of market and technology changes. On the technology front, PV modules are becoming less hail-resistant over time as manufacturers push the value-engineering envelope with larger format products and thinner front glass. Meanwhile, project development in the United States is increasing in states such as Texas and other hail-prone regions.

Fielding hail-resistant modules in more hail-prone locations requires better risk mitigation practices. “To bridge the needs of the insurance, project developer, and finance communities, we need to promote the deployment of more resilient systems,” says Sara Kane, co-leader of the power and renewables practice at insurance brokerage CAC Specialty.

Large-diameter hail risk is inevitable in some parts of the world, but large project losses are not. Here are some lessons learned about – and best practices for identifying, quantifying, and mitigating – severe hail risk in active solar assets.

Regional issue

Hail forms when convective storm updrafts carry water droplets into extremely cold areas of the atmosphere where they freeze and grow via accretion. The National Oceanic and Atmospheric Administration (NOAA) broadly characterizes hail threat based on hailstone size. According to these basic categories, “severe hail” has a diameter greater than 19 mm and “significant hail” has a diameter greater than 50.8 mm.

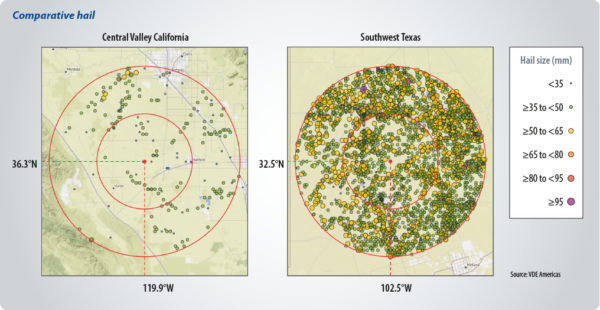

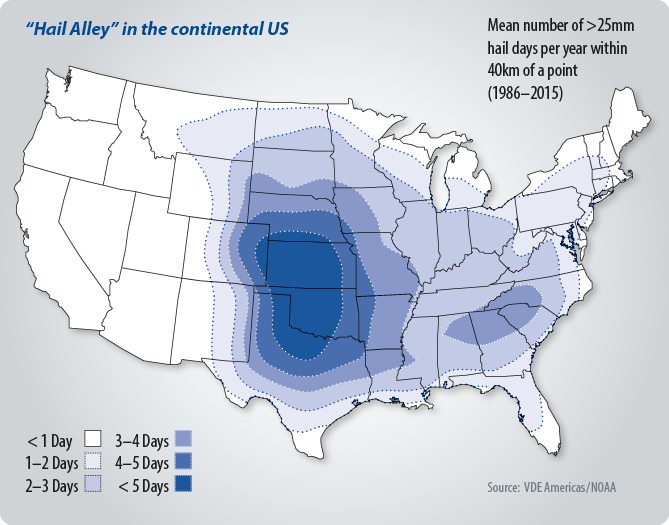

Though hail can form anywhere that experiences thunderstorms, the NOAA’s hail climatology maps of the continental US reveal a distinct “hail alley” that extends from West Texas in the south up through the Dakotas in the north. Viewed from this regional perspective, severe hail risk exists for most US project locations east of the Rockies.

Local risk

The insurance industry has generally thought about hail risk across relatively large areas, such as one-degree longitude by one-degree latitude, which is roughly 10,000 km2. Unfortunately, this perspective is not well suited to characterizing hail risk at the scale of roof- or ground-mounted solar assets. “Hail perils are much smaller in spatial scale relative to other hazards typically considered by insurers,” explains John Allen, a climate scientist who specializes in forecasting hail incidence and size at operational timescales. “Examining long-term probabilistic hail loss at a local level requires novel approaches that combine the strengths of multiple datasets.”

To support VDE Americas’ risk assessments, Allen developed a tool that uses big data analysis to blend ground observational information with radar-based data points in a way that addresses the limitations and biases of individual datasets.

Little protection

Core PV module safety and performance standards are pass/fail in nature and do not differentiate product designs based on long-term, in-field durability. International Electrotechnical Commission (IEC) standards for flat-plate PV modules include ballistic-impact tests. However, the kinetic energies are modest and inadequate to characterize resilience to severe hail.

“The vast majority of modules are unscathed by the impact tests required for module certification,” says Cherif Kedir, president and CEO of Renewable Energy Test Center (RETC). “To understand hail resilience, we need to investigate impact resistance at the threshold of damage, just over this threshold, and at material failure. This requires kinetic energies in excess of 20 joules.”

According to IEC 61215, product designs must withstand 11 impacts of a 25 mm ball of ice traveling at terminal velocity, which results in an impact force of 1.99 joules. In other words, the kinetic energy is an order of magnitude less than that required to characterize hail resistance over the lifespan of a PV power plant.

Enhanced tests

Module manufacturers and testing laboratories must subject product designs to higher impact energies to better understand severe hail effects in real-world applications. Unlike certification tests, enhanced stress tests are not pass/fail in nature. Rather, beyond-certification tests provide comparative data that differentiates product designs.

In May 2019, hail damaged roughly 400,000 modules at the Midway Solar farm in West Texas, resulting in a previously unimaginable $80 million of insured losses. In response, RETC designed the industry’s first enhanced testing program for severe hail.

“The HDT [Hail Durability Test] program expands and improves upon UL and IEC requirements,” explains Kedir, referring in the first instance to the safety body formerly known as Underwriters’ Laboratories. “First, the program subjects modules to higher kinetic impact energies to better reflect the risk posed by hail over a 25- or 30-year operating life. Second, it thoroughly investigates a range of possible outcomes – from cell cracking to glass breakage – which provides valuable data for probabilistic analyses. Third, the HDT program includes thermal cycle and hot-spot tests to reveal potential long-term module degradation modes.”

Stakeholders developing projects in hail-prone regions should encourage or even require module suppliers to provide these beyond-certification hail test data and make system design and product procurement decisions accordingly.

Front glass thickness

In the absence of product-specific data, front glass thickness provides a general indication of hail resilience. Anonymized hail durability test data indicates that PV modules with thinner front glass are less resilient to large-diameter hail, as compared to modules with thicker front glass.

This is partly due to the fact that thinner glass has less cross-sectional area to absorb a shock without shattering. Additionally, thinner front glass materials cannot be fully tempered via traditional means and must be strengthened via alternative methods.

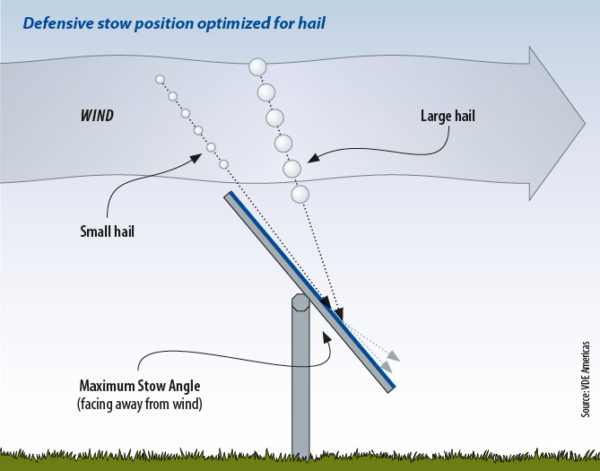

The impact energies of a hailstorm vary based on the array-tilt angle and the direction and speed of the wind. Although array-tilt angles are generally fixed in roof-mounted applications, tracker-mounted systems are not static. This ability to move out of harm’s way in advance of an approaching storm is relatively unique within the built environment.

Many large-scale PV systems integrate intelligently controlled single-axis trackers that can execute peril-specific defensive stow strategies. Leveraging these capabilities, plant operators can manually or automatically rotate a tracker-mounted PV array to an optimal tilt angle for hail risk mitigation. This defensive posture will reduce hail-impact energies and the exposed hail-field impact area, effectively decreasing the number of direct hail strikes and decreasing hail-impact energies.

Hail mitigation

Generally speaking, tracker-mounted PV modules are most vulnerable to hail in a horizontal position, as is the case at solar noon. Impact energies are greatest when hail strikes are perpendicular to the plane of the array. Moreover, the exposed impact area is largest when an array is stowed at zero degrees. Some trackers are also susceptible to wind-induced instability when the modules are flat.

If plant operators want to move an array through a horizontal position in advance of a storm, they must factor in the time required to safely complete this operation ahead of approaching winds. For best results, work with the tracker provider to reduce latency and improve stow-response speeds.

Exercising caution can ensure that the right steps are taken to mitigate hail risk while not increasing risk of wind-related damages. During severe convective storms, the direction of the wind is uncertain and may even be variable and swirling. Whether it is better to rotate into or out of the dominant wind direction will depend on hardware and storm-specific variables.

All else being equal, maximum hail mitigation is accomplished by rotating the array to the maximum tilt angle facing out of the wind, as this results in the smallest possible impact energies and exposed area. Unfortunately, facing out of the wind also results in a large sail effect, which may induce wind-stability issues.

Successfully stowing modules ahead of a severe hailstorm requires contracting with a reputable early-alert weather service. A sophisticated provider will be able to send advanced warning regarding expected storm-approach direction, maximum hail diameter, and lead time. Plant operators can use this information to trigger a situationally appropriate risk-mitigation response.

Large-scale projects fielded in hail-prone regions should include hail sensors as part of a plant monitoring system. Catastrophic hail events are not only costly and painful for all involved; they also present a unique learning opportunity. Hail sensor data are useful for forensic analyses of both damaging and non-damaging events, as well as to target remediation efforts. These empirical data can also help improve hail risk assessment models and future mitigation strategies.

Knowledge is power

Informed by intelligently hybridized weather data and product-specific hail resiliency data, engineering reports can characterize hail risk at the local scale of a PV power plant. Insurance brokers such as CAC Specialty are already using the outputs from these science and engineering-based hail risk assessments to inform stochastic simulations that examine long-term probabilistic loss based on occurrence intervals and product and project-specific vulnerabilities.

To better support a broader industry ecosystem, VDE Americas is prioritizing the development of a web-based software platform based on the analytical engines driving our hail risk assessments. The goal of this initiative is to provide the solar industry with a conduit to quality probabilistic data related to hail risk and its financial implications.

Empowered by hail risk assessment data, project stakeholders will be able to rapidly analyze, iterate, and optimize plant designs based on site-specific and product-specific characteristics. It is likely manufacturers, developers, engineers, asset managers, and sponsors will use this data in ways that cannot be imagined today, creating additional mitigation benefits and technology or business model innovations.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.