Researchers at the Politecnico di Torino in Italy have designed a cooling system for photovoltaic panels that uses radiative coolers based on cementitious materials. These coolers are often used for thermal management in buildings and have strong potential due to the low costs of the concrete materials they are made with.

Radiative cooling occurs when the surface of an object absorbs less radiation from the atmosphere and emits more. As a result, the surface loses heat and a cooling effect can be achieved without the need for power.

“Our work was intended at determining the thermodynamic limit of the radiative coolers,” researcher Matteo Cagnoni told pv magazine. “In order to establish this limit, we considered the various terms of energy exchange between the solar cell, the cement-based cooler, the atmosphere, and the sun, which enables us to determine the maximum temperature reduction induced by the thermal coupling between the cell and the concrete substrate.”

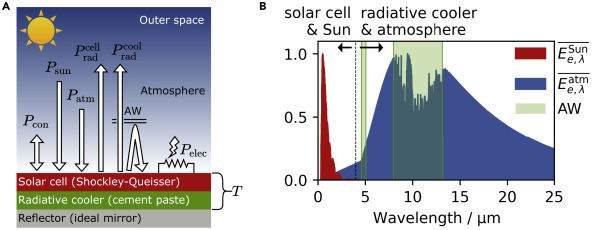

The experimental simulated system consists of a stack made by a reflector, a cement-based radiative cooler, and a bifacial solar cell.

“This structure could be realized, for example, by building a thin film solar cell onto a cement-based substrate by sputtering, evaporation or solution deposition techniques,” the scientists explained, noting that the solar cell and the radiative cooler are thermally coupled and mutually transparent.

The academics found that the cooling technique could reduce the operating temperature of silicon-based solar cells by up to 20 kelvin (K), which could eventually result in efficiency improvements of about 9% and an increase in module lifetime of around 400%.

“We expect this solution to be very attractive for the market, especially if one considers building-integrated photovoltaics (BIPV),” Cagnoni said. “For example, one could try to implement the theoretical system as a solar cell coupled to a roof tile. The cost of this solution may be only slightly higher than the cost of the photovoltaic panel itself, as cementitious materials are very cheap, highly scalable and robust.”

He said the additional complexity of the system involves the fabrication of the solar cell on a cement-based substrate by thin-film methods, or by thermally coupling a bulk solar cell with a cement-based slab. This additional cost is expected to be largely compensated by the gains in solar cell efficiency and system lifetime that a reduced operating temperature would induce.

“For example, a 20 C temperature reduction could lead to efficiency gains up to 9% in silicon solar cells, and up to a four-fold lifetime extension,” Cagnoni stated. “Of course, these are theoretical upper limits, but they suggest that significant gains are achievable also in the real physical devices.”

The Italian group described the new cooling technique in “Cementitious materials as promising radiative coolers for solar cells,” which was recently published in iScience.

“These works can provide a starting point for the practical implementation of our attractive concept and pave the way toward more efficient photovoltaic systems,” the group concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.