As solar becomes an increasingly large proportion of the energy mix, there’s a problem with the dominance of silicon in panel production. Silicon accounts for 95% of the 14 GW of solar module generation capacity installed in the UK. That solar fleet provides just 4% of the UK’s energy demand. The government’s 2022 energy strategy calls for a five-fold increase in solar capacity, to 70 GW, by 2035. However, looking to silicon solar for the additional 56 GW presents significant ethical, economic, and security implications and that prospect is driving research into alternatives, which is where perovskites come in.

Manufacturing silicon panels is costly and complicated and, as the UK does not have significant silicon solar manufacturing capacity, we will continue to rely on imports. As the world has learnt of late, geographical concentration of global supply chains presents energy security and logistics challenges. Manufacturing solar panels has a high carbon footprint and the average carbon payback period for a silicon solar panel – the length of time a panel will have to generate electricity before it cancels out the carbon emissions its manufacture embodies – sits at 300 days to 350 days.

Also, the rigidity and bulk of silicon solar panels typically limits their application to ground-mounted solar farms and installation on load-bearing roofs. For example, a gigawatt of solar generation capacity requires around 2.5 million panels. To achieve the 70 GW required by 2035 is going to take a massive land grab. Little wonder the International Energy Agency is calling for diversification in solar PV manufacturing.

Are perovskites the answer?

There has long been interest in the potential use of perovskites for solar power generation, thanks to the superconducting and electronic properties observed in the crystal, which is found in abundance in the Earth’s mantle. The fact cheaply available perovskites have remarkable properties for absorbing light photons to create an electron flow and generate electricity position the material as an ideal candidate to supplant silicon in solar generation.

With so much interest in perovskites, enterprizing manufacturers are looking for innovative ways to incorporate them into PV production and my company, Power Roll, is no exception. We have patented a technique that applies perovskites to a flexible, lightweight substrate: polyethylene terephthalate (PET) – an industrial thermoplastic sheet. The PET substrate is embossed with tiny v-shaped channels or “microgrooves” that are no more than one or two microns wide.

Roll-to-roll

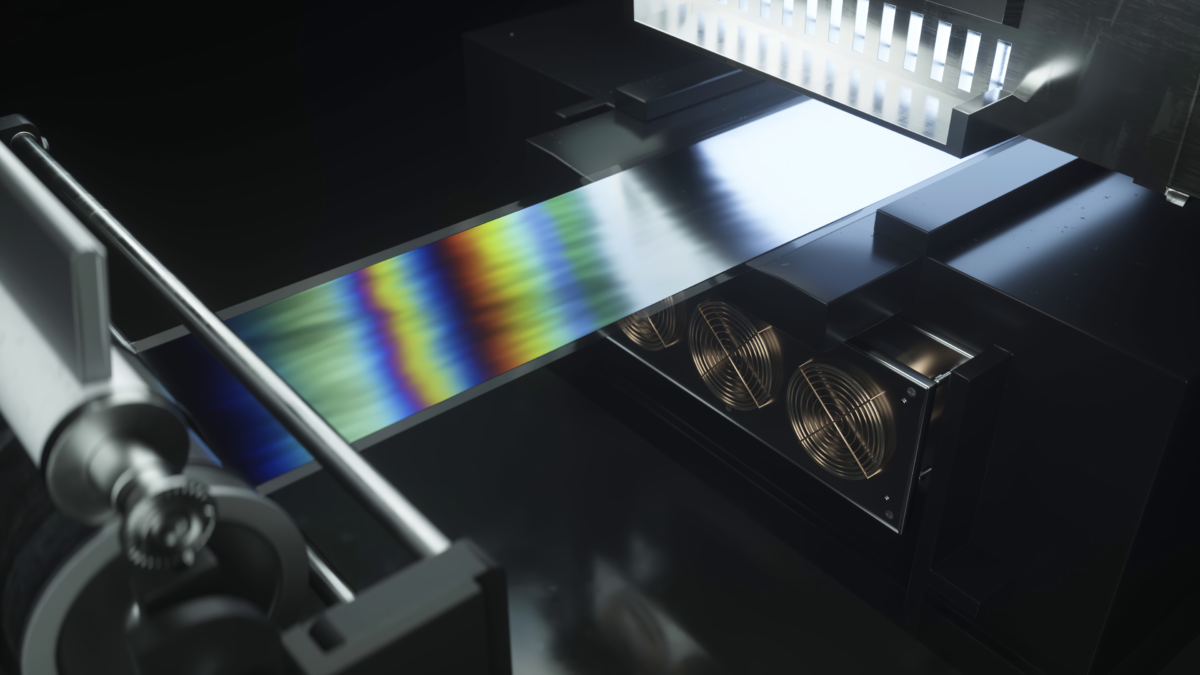

The microgrooves are printed extremely accurately onto the heat-stabilized PET using a roll-to-roll process. They form conductive pathways that are designed to optimize the flow of electrons and “tune” the electrical output of the solar module. The walls of the microgrooves are coated with metals, as the electrodes, followed by an oxide layer that acts as the electron transport layer (ETL) and hole transport layer (HTL). The perovskite ink is printed into the grooves over the ETL/HTL layers to produce an ultra-thin, flexible solar cell, or “solar film” that is 100 times thinner than silicon solar panels.

Roll-to-roll manufacturing is a simple and scalable process used in other low-cost sectors such as packaging, and is key to the low cost of solar film. Importantly, it skips several production steps involved in other flexible PV technologies.

After perovskite ink coating and annealing – the latter a heating process to aid pliability – a pressure adhesive barrier film is applied over the top in a continuous process to protect the crystallized perovskite. Further barrier films and a foil back sheet can be applied using either pressure or vacuum lamination.

To research cost-to-durability ratios, Power Roll has performed weekly tests on various barrier films and lamination types that have been exposed to outside conditions over the last six months. This has demonstrated that films with high cost-barriers and vacuum lamination show no degradation of performance while those with low cost-barriers and pressure lamination have been affected at the edges. Further testing is ongoing.

Power Roll’s methodology produces perovskite PV with a manufacturing cost five times cheaper – and a carbon payback period up to ten times shorter – than traditional silicon solar panels.

Wide-ranging application

The combination of microgrooves and perovskites produces flexible, lightweight, efficient solar film at a fraction of the cost of silicon solar panels. The flexible nature and simple installation process means that perovskite solar film can be installed in situations where silicon solar panels cannot be deployed. For example, it can be integrated with windows, blinds, vehicles, low-load bearing roofs, and vertical surfaces. While solar panel farms take up significant amounts of green space, perovskite PV can make use of areas that have already been developed for commercial or domestic use.

The largest market for solar film is in commercial and industrial rooftops. Just a quarter of the UK’s 2.5 billion square meters of south-facing rooftops could generate 30% of the UK’s energy requirement. Perovskite PV solar film can be installed on non-structural rooftop space cheaply and at scale, helping the UK meet its energy security and net-zero goals.

And opportunities for lightweight solar film extend beyond the UK. The manufacturing process is easy to replicate and can be licensed globally, to help accelerate solar energy deployment. With less than 2% of global rooftops hosting solar installations, there is a massive opportunity for lightweight, low-cost perovskite PV. Solar film is versatile and has the potential to be integrated on rooftops and across a wide range of surfaces. It will help improve the accessibility of clean energy generation in areas of the world that are currently lacking any significant renewables infrastructure. Perovskite PV is expected to come to market as soon as next year, with wider adoption by 2025, and promises to revolutionize the solar sector.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

This sounds most impressive but certain questions are not addressed:

What is the sunlight-to-electricity efficiency of this product? This will always be important.

What is the composition of this perovskite — does it contain toxic compounds?

What is the expected useful lifetime of these rolls when deployed, exposed to sunlight?

Can recycled PET (“plastic bottles” etc) be used? If Yes, then fantastic.

After 40+ years of intense R&D silicon has set some high benchmarks. To supplant silicon this roll technology will have to demonstrate decisive advantages, such as reduced cost and lower carbon footprint, as you claim. Only if answers to these and other questions are satisfactory will this product be able to prevail over silicon.

But PV technology is still wide open and the intense research going into perovskites can be expected, in the long term, to produce performance superior to silicon and open up a raft of new possibilities.

Good luck!