ITRI (ITRI) and Taiwanese panel manufacturer URE claim that their new PV module is easier to recycle, with minimal PV waste, because it is so easy to disassemble. According to ITRI, 96% of the materials in the module can be recovered, including all of the solar cells and encapsulation glass.

“The cells can be restored to the bare silicon wafer via a reverse dismantling process, and then produced into regenerated cells for use in the manufacturing chain of PV modules,” ITRI’s R&D team told pv magazine.

Image: ITRI

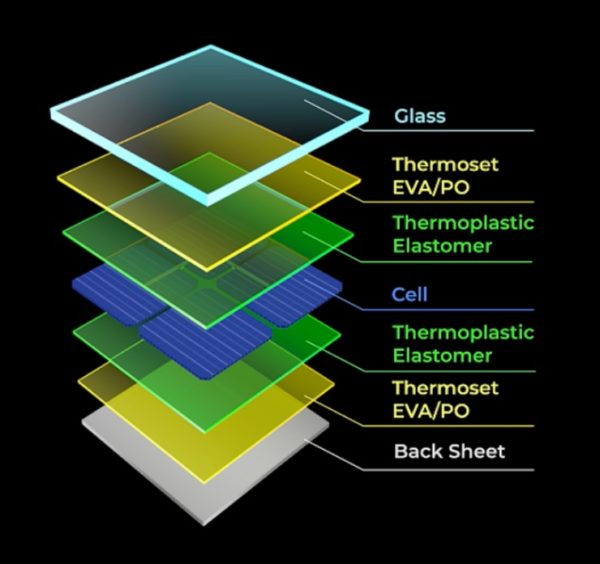

The two entities claim their technology improves on the traditional module structure, which uses thermoset ethylene-vinyl acetate (EVA) or polyolefin (PO) as encapsulants. These bond materials tightly together, complicating their separation during the recycling process.

By contrast, their new solution uses a thermoset EVA/PO and thermoplastic elastomer (TPE) bi-layered compound as encapsulation material. The bi-layer serves as a buffer, protecting the cells from cracking during the dismantling process. The solution also takes advantage of the melting point of TPE when the module is heated for disassembly.

“The designed low-temperate thermal process gradually decomposes the bi-layer film,” the R&D team said. “By the time the solar modules become obsolete, the module can be easily dismantled into various parts.”

Unlike the processing of commercial-use modules, ITRI says the improved process recovers glass and silicon wafers as a whole, rather than as pellets. It claims that this allows for silver to be extracted from the intact solar wafers.

pv magazine print edition

The R&D team estimates that the technology increases the value of recycling PV modules from around $18 million to $74 million per gigawatt. The manufacturing process is purportedly the same as for standard modules.

ITRI developed the technology, while URE was responsible for the design and production. The module is in compliance with the IEC 61215 and IEC 61730 safety and reliability standards, certified by TÜV Rheinland.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.