The solar industry has been interested in heterojunction (HJT) technology for many years. However, it requires the use of n-type silicon wafers, and wafer producers used to prefer lower-cost p-type wafers.

This year, HJT is again looking like the best way to improve cell performance. Wafer makers are beginning to produce n-type products at scale and are pursuing various cost-optimization strategies to close the gap with p-type products.

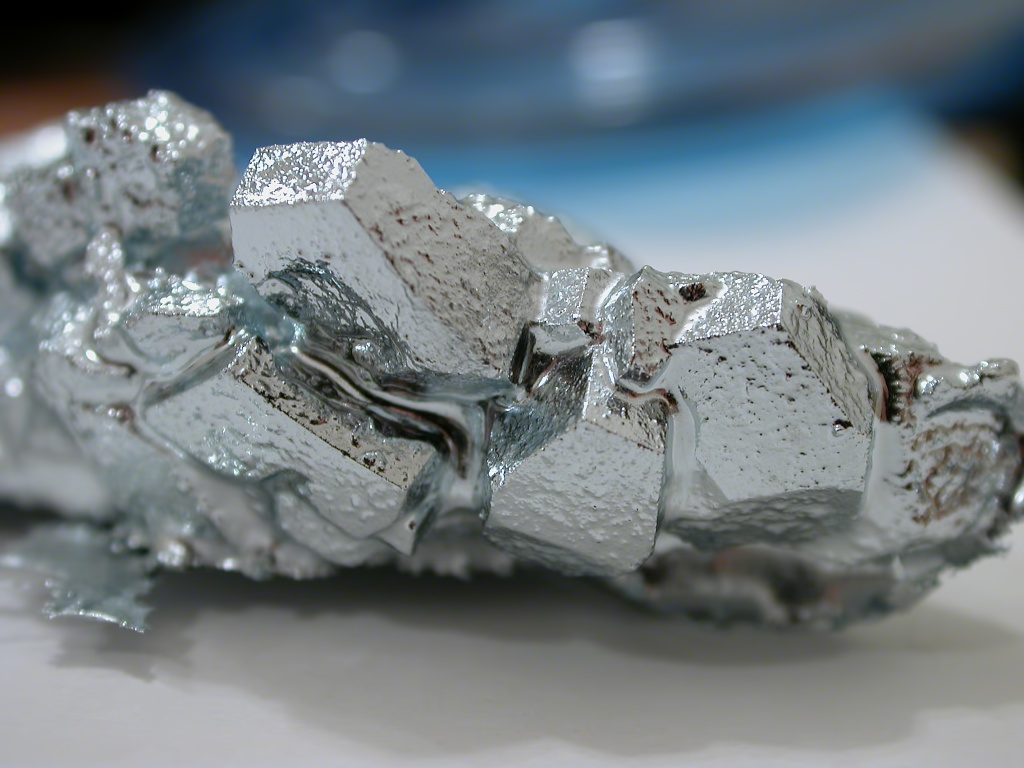

However, some people in the PV research community are choosing to pursue the alternate strategy of developing p-type wafers for HJT cell production, to match the performance of n-type. The introduction of gallium doping to p-type cell production has opened a lot of doors for this research, offering a solution to light-induced degradation that doesn’t require high temperatures. There are still some unanswered questions, but recent research has shown that p-type wafers could be used to fabricate HJT cells that rival the performance of n-type.

Scientists led by French research institute CEA INES demonstrated this potential by fabricating p-type HJT cells on a pilot line at their laboratory. Using wafers cut from a specially produced ingot with a low level of gallium doping, the group was able to demonstrate a best efficiency of 24.47%, and results consistently well above 23%.

“This work clearly suggests that the p- to n-type SHJ solar cell efficiency gap can be reduced without costly additional and/or more complicated process steps,” said the group. “The cells behave in a similar way to the n-type reference, which seems very promising for field applications.”

The researchers described the cells in “Closing the gap between n- and p-type silicon heterojunction solar cells: 24.47% efficiency on lightly doped Ga wafers,” which was recently published in Progress in Photovoltaics. Based on previous research, the group worked on an assumption that p-type performance needs to be within 0.4% of that of n-type to be viable on cost basis.

The group said that more investigation will be needed on the cost of the moderate to low doping level for the ingots it procured specifically for this work. They also note that this time around, they fabricated the p-type cells based on standard process parameters used in n-type production, and that further optimizations to many of these might be possible to close the gap even further.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.