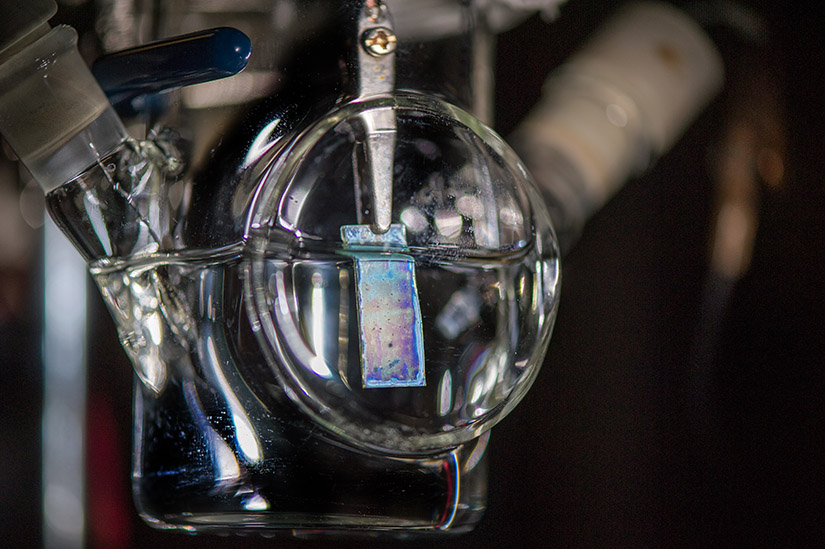

The US Department of Energy’s National Renewable Energy Laboratory (NREL) and the Lawrence Berkeley National Laboratory (Berkeley Lab) have published a protocol for standardized PEC water-splitting efficiency measurements, similar to the certification system in place to for PV cell efficiency. “It’s really difficult to compare reported PEC water-splitting efficiency results between labs, because people tend to make measurements under different conditions,” said Todd Deutsch, a senior scientist at NREL and co-author of “Best practices in PEC: How to reliably measure solar-to-hydrogen efficiency of photocathodes.” The paper, published in Frontiers in Energy Research, proposes uniform experimental practices, starting with materials for the fabrication of photoelectrodes. The researchers have also proposed a fabrication procedure, an experimental setup, and a process to measure solar-to-hydrogen efficiency.

University of Malaya researchers and University of the Punjab scientists have jointly investigated the feasibility of hydrogen as a primary combustion fuel for municipal solid waste (MSW) incineration, by designing a vertical shaft-type incinerator that can operate on pure hydrogen. “The hydrogen-based incinerator exhibited the highest performance for homogenous paper and food waste (1 kg) with 60% and 87% moisture content, respectively,” the team wrote in “Hydrogen as potential fuel for solid waste incineration for a sustainable waste management,” which was recently published in Institute of Electrical and Electronics Engineers Access. They fed a pre-mixed hydrogen and oxygen fuel through burners to achieve homogenous heat distribution, with tests on different MSWs, and moisture percentages from 60% and 90%. The maximum recorded temperature of the incineration was 850 C. They said an increase in moisture content of the waste could reduce the performance of the hydrogen-based incineration system.

The European Commission has launched its third call for large-scale projects under the EU Innovation Fund with a budget of €3 billion ($2.9 billion), thanks to increased revenue from auctioning EU Emissions Trading System (ETS) allowances. It has allocated €1 million for general decarbonization processes and €2 billion for innovative electrification in industry and hydrogen. It has also set aside €700 million for innovative projects in the production of components, including final equipment for electrolyzers and fuel cells, renewables, energy storage, and heat pumps. The call is open for projects in EU member states, Iceland, and Norway until March 16, 2023. Hydrogen Europe said it welcomes the introduction of a dedicated facility targeting the deployment of new electrolyzer and fuel cell factories.

Delgaz Grid, the natural gas and electricity distribution unit of E.ON Romania, is starting a pilot project in November to test the compatibility of user installations and distribution system components, with a mixture of natural gas and hydrogen. “The project will run from November 2022 to October 2024 and aims to analyze and demonstrate that it is technically feasible and safe to add hydrogen, at 20% by volume, to existing natural gas distribution networks and utilization facilities in Romania,” said the company.

Cummins will start producing electrolyzers in the United States and expand PEM electrolyzer production capacity at its factory in Oevel, Belgium, to 1 GW. The company said in its third-quarter results that it will make electrolyzers in Fridley, Minnesota, starting at 500 MW of annual manufacturing capacity, but scalable to 1 GW “in the future.”

Fortescue Future Industries (FFI) and Enel Green Power have announced plans to jointly explore the co-development of the green hydrogen value chain, with an initial focus on Latin America and Australia. The companies said they aim to make green hydrogen cost-competitive with fossil fuel-based alternatives within this decade.

Centrica and Equinor have signed a cooperation agreement to explore the development of a “low-carbon” hydrogen production hub in Easington, England. “Currently, up to one-third of the UK’s total gas supply enters via Easington, much of it from Equinor’s Norwegian facilities,” said Centrica, adding that the area is close to some of the world’s largest offshore wind farm developments.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.