The solar industry’s adoption of bifacial cells, which is expected to represent more than half of all silicon PV cells on the market this year, required a few rapid shifts in module design, focused on maximizing the amount of light that can be absorbed from the module’s rear side. And changes to the materials used in a module, as well as to the way it operates, can affect its performance in the field. Several performance issues unique to bifacial technologies have been noted in research and in the field, and even as bifacial becomes a mainstream PV technology, understanding of these problems is still developing.

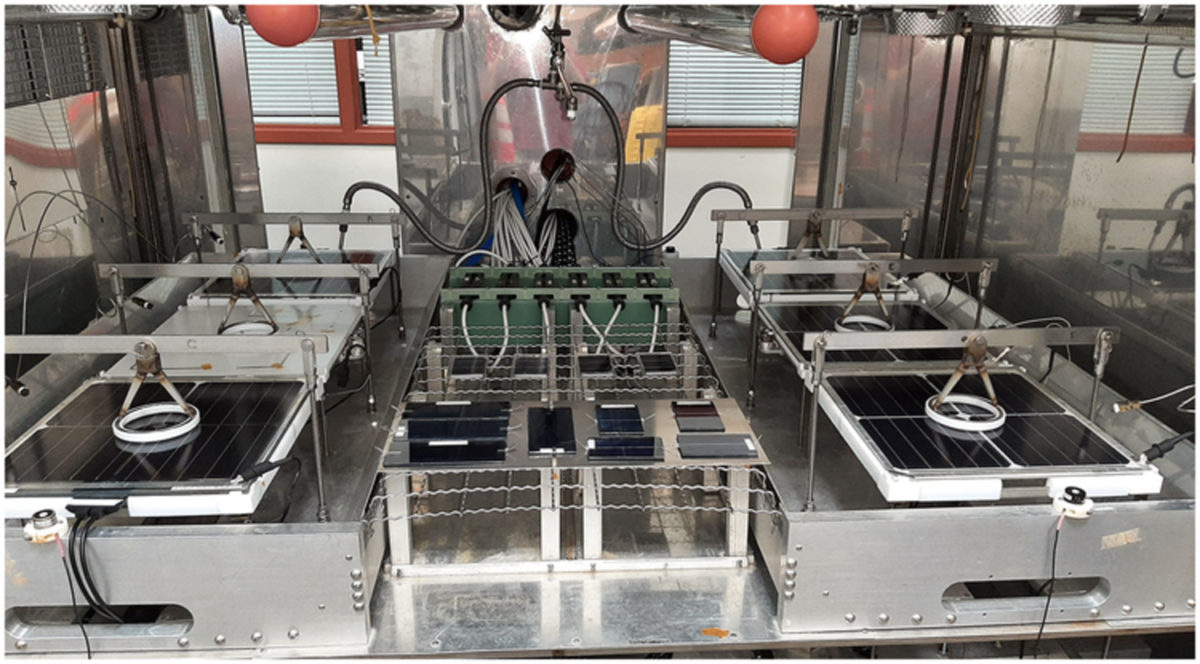

Scientists led by the US National Renewable Energy Laboratory (NREL) have sought to gain a clearer picture of these issues. They put a range of different bifacial module configurations through a series of tests designed to mimic the most extreme of conditions the modules could experience in the field. This series of “combined accelerated stress testing” (C-AST) exposes modules simultaneously to varying temperatures, humidities and voltages, as well as mechanical stress. NREL introduced the C-AST testing protocol in 2020 and sees it is a vital way for the solar industry to understand performance loss in different technologies.

This latest work put PERC cells in both glass-glass and glass-backsheet setups, and devices encapsulated with POE and EVA, through multiple cycles of C-AST testing. The devices tested were “mini modules” each consisting of four 156 mm x 156 mm cells. The results are available in the paper “Evaluation of bifacial module technologies with combined-accelerated stress testing,” which was recently published in Progress in Photovoltaics.

The glass-glass modules were shown to have many more breaks in the grid fingers compared to those using a backsheet – they counted on average 124 breaks in grid fingers for the glass-glass devices, compared to 42 for glass-backsheet. The group attributes this to increased rigidity of the glass.

“On the one hand, if the cell is closer to the neutral plane of the module laminate and the module is more rigid when uniformly encapsulated in glass, it may be expected that the stress on cells and cell cracking is reduced,” they said. “On the other hand, this rigidity may be a disadvantage leading to increased stress if the cell is impeded from deforming, for example, due to strain associated with thermal coefficient of expansion mismatch.”

The testing also found potential-induced degradation, which was highest in glass-glass modules encapsulated with EVA, and that similar results were seen with cells tested in the field over a longer period.

“The results of C-AST show that use of bifacial cells and modules can increase the prevalence of failure modes such as grid finger breaks and PID,” they said. “Consideration must therefore be given to the choice of packaging materials and processes for their mitigation. C-AST indicated that that use of the POE and transparent PVF backsheet reduced propensity for polarization-type PID in glass-glass modules.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.