Researchers from Germany's Fraunhofer Institute for Solar Energy Systems (ISE) and German laser-enhanced contact optimization (LECO) have worked with Cell Engineering GmbH to increase the power conversion efficiency of a tunnel oxide passivated contacts (TOPCon) solar cell by 0.6%, mainly by using LECO as a post-firing treatment.

The new process, patented by Cell Engineering GmbH in 2016, replaces the conveyor belt furnace (FFO) technology that is commonly used for TOPCon cells and needs peak temperatures higher than 700 C. FFO is known to improve the cell fill factor, but it also leads to increased metal-induced recombination, thus lowering the open-circuit voltage and cell overall efficiency.

“In this work, the use of laser-enhanced contact optimization (LECO) as a post-firing treatment is applied to reduce the contact firing temperature, which enables higher open-circuit voltage and simultaneously higher fill factor values on industrial TOPCon solar cells,” the scientists said.

The LECO process consists of using a highly intense laser pulse on the front side of the solar cell at a constant reverse voltage of more than 10 V, with the resulting current flow of several amperes considerably reducing the contact resistivity between semiconductor and metal electrode.

The German group tested the new approach on TOPCon solar cells with a poly-Si thickness of 80 and 170 nm, respectively.

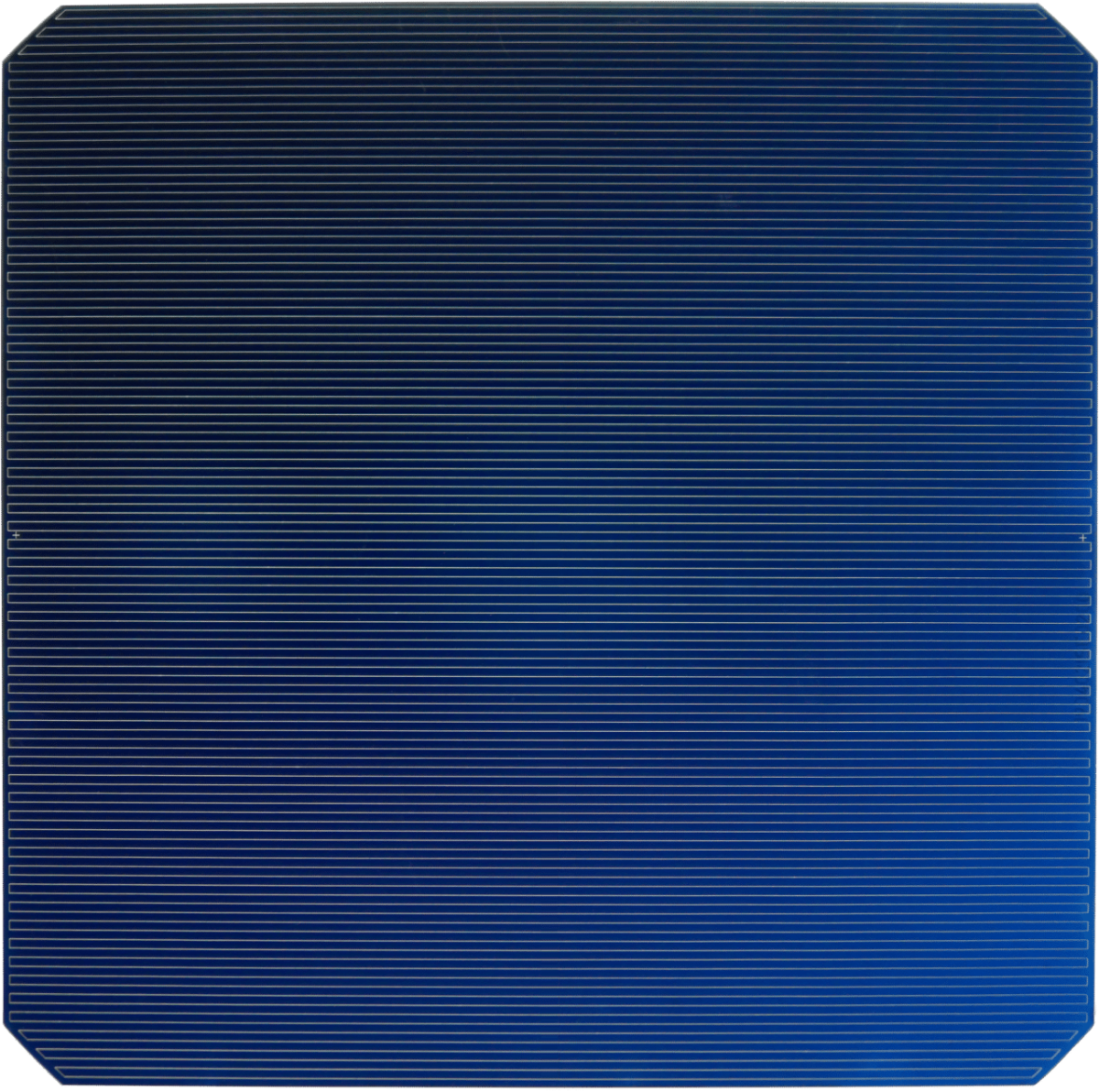

“The cell's architecture utilizes a boron diffused p+ emitter passivated with a layer stack of a thermally grown silicon dioxide (SiO2), plasma enhanced chemical vapour deposition (PECVD) aluminum oxide (AlOx), and silicon nitride (SiNx) layers, an n-type bulk and on the rear the eponymous TOPCon layer,” the researchers explained. “During the anneal, phosphorus diffuses through the thin oxide, creating a tail within the crystalline silicon enabling excellent passivation qualities. Simultaneously, the deposited a-Si crystallizes into a poly-Si. The TOPCon layer is then capped with a PECVD SiNx layer serving as anti-reflection-coating and hydrogen source, crucial for fully activating the passivation.”

The academics determined that the efficiency of the champion solar cell built with the new LECO technique achieved an efficiency of 24.1%, which compares to 23.8% for a reference cell developed without LECO.

“These results match those from Heraeus where they estimated a potential gain for this type of cell of 0.52%,” the scientists said, noting that the best performing call also achieved a fill factor of 81.6%, an open-circuit voltage of 706 mV, and a short-circuit current of 41.3 mA/cm2.

The scientists presented their findings in “Laser-enhanced contact optimization on iTOPCon solar cells,” which was recently published in Progress in Photovoltaics.

“The LECO process can do more than simply improving the average performance of a solar cell; it allows for an overall fine tuning of the whole process sequence and a more homogeneous contact resistivity leading to a narrower fill factor distribution,” they concluded. “On both sides, it allows for thinner and lower doped layers, and potentially the use of additional or thicker dielectric layers that are more resilient to penetration by metal pastes, a reduction of the metal area fraction and extended firing or annealing conditions.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.