A perovskite solar cell can only be as good as the materials that go into it, and of all the many approaches to improving their performance and stability, and developing processes to produce them at scale, those that focus on the precursor materials that go into the perovskite layer have received comparatively little attention.

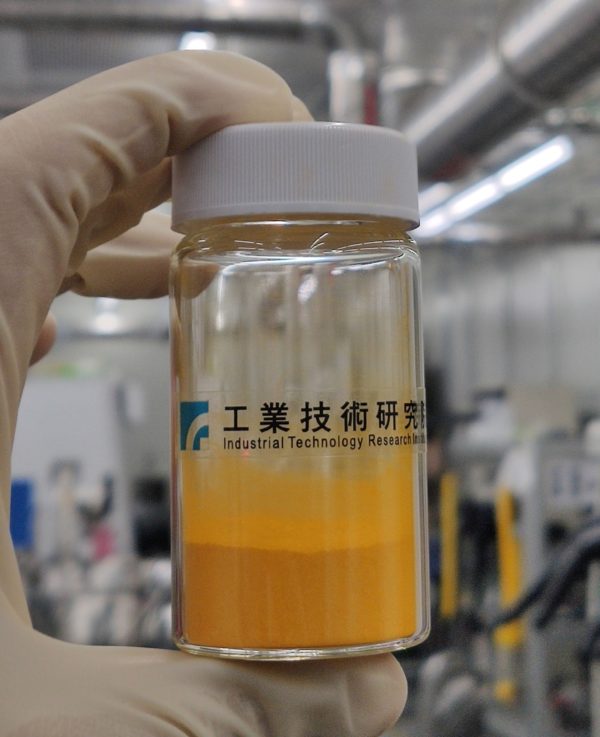

A group of scientists led by the Industrial Technology and Research Institute in Taiwan worked on the fabrication of lead-iodide (PbI2), an element in virtually all of the best perovskite solar cells produced to date. They built on earlier research that has shown the purity and formation of this material could be a key factor in performance once it is integrated into a solar cell.

The group’s latest work demonstrates how the crystalline structure and orientation of PbI2 ultimately have a significant impact on cell performance. The researchers also introduce a simple way to control this using temperature during synthesis. They described their findings in “A novel method to control the crystallographic preferred orientation of lead iodide toward highly efficient and large-area perovskite solar cells,” which was recently published in RRL Solar.

ITRI/Pei-Ting Chiu

By varying the temperature during synthesis of PbI2 the group noted significant changes in the way the crystals formed, and these had a major effect on the cell performance. “Horizontal planes … are beneficial for black FAPbI3 perovskite crystals while the lateral facets … lead to the formation of δ-FAPbI3 which is known as the yellow phase of perovskites and has no photo-activity,” the group explained.

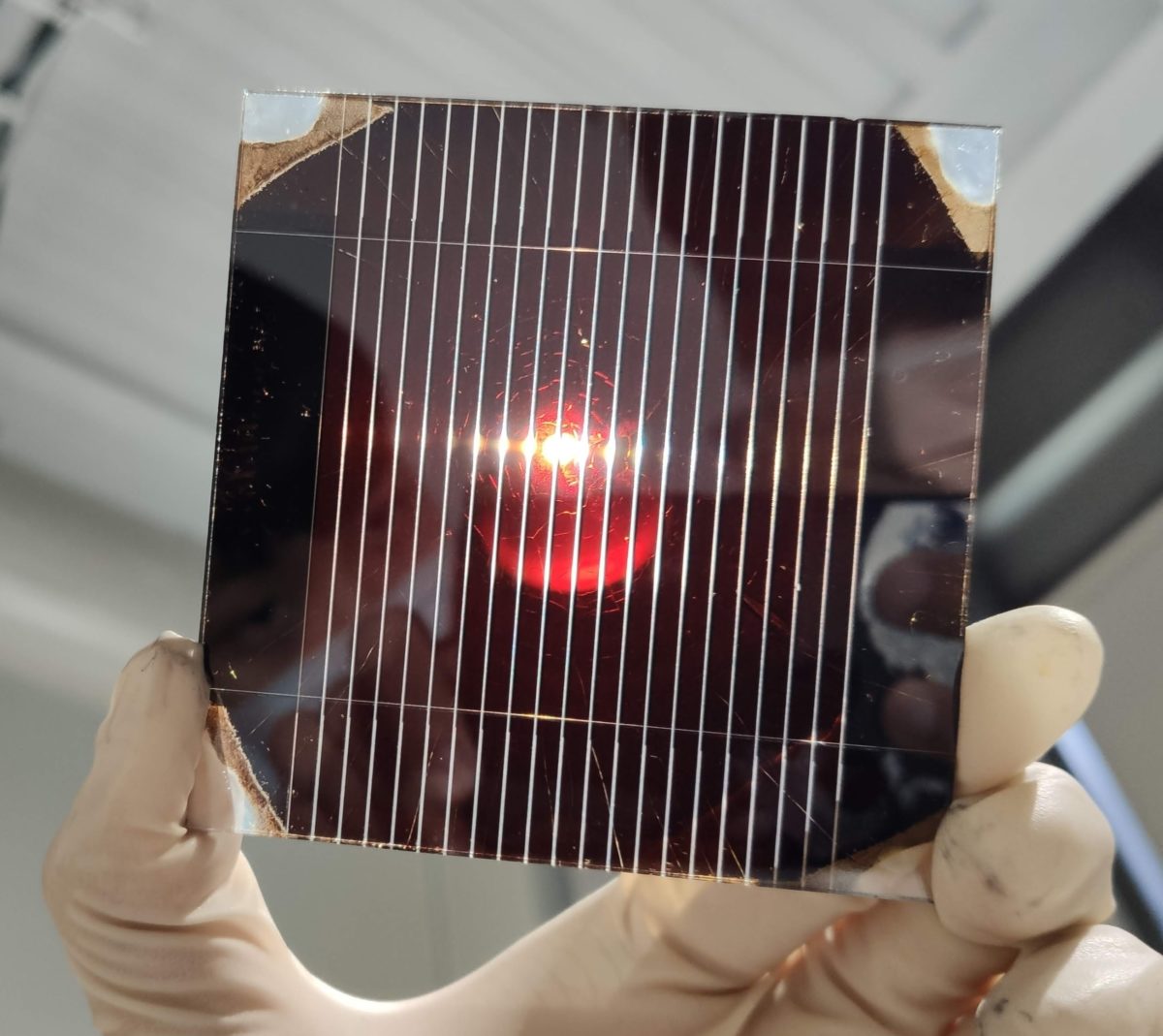

And when fabricated into cells, PbI2 synthesized at higher temperatures (120 C) was the top performer, with the temperature causing more growth of the desired horizontal facets. Cells made with PbI2 synthesized at 25 C came out at just 8.8% average efficiency, while those with the material processed at 120 C reached an average efficiency of 17%, with a champion cell in the batch measured at 17.96%. And these cells were scaled up to an area of 3.68 square centimeters, achieving 16.08% efficiency, which the group sees as strong potential for its approach to be worth investigating for larger area devices.

“The industrialization of perovksite modules is inevitable,” the group concluded. “Providing reliable and cheap precursors is the key to fabricate PSCs as a competitive product in the solar cell market in the future.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.