Organic solar cells (OSCs) have long been regarded as a promising next-generation PV technology due to a wide range of advantages, such as their light weight, flexibility, semitransparency, and customized color and shape. However, most OSCs are produced by the spin-coating technique, which allows for relatively high power conversion efficiencies, but with poor scalability.

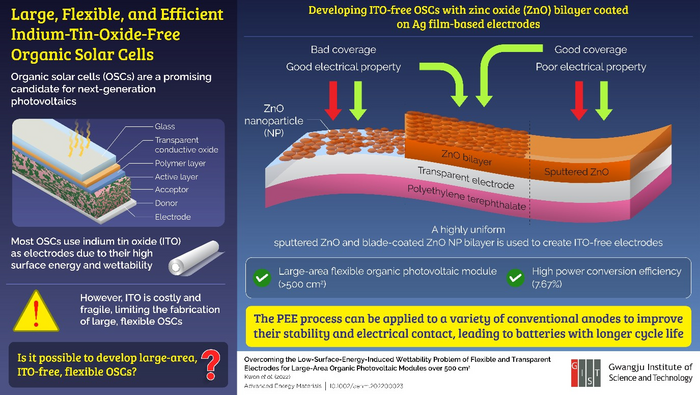

A further obstacle to the commercialization of OSCs is that the most commonly used flexible electrode, indium tin oxide (ITO), makes them expensive and too fragile for large-area modules. But researchers at the Gwangju Institute of Science and Technology (GIST) in South Korea have developed a new way to create OSCs with zinc oxide (ZnO), overcoming the issues of cost and scalability. The team used sputtered ZnO and a ZnO nanoparticle layer obtained through a blade-coating technique, in order to create a uniform bilayer on an ultra-thin silver film electrode.

“The ultra-thin silver film electrode with ZnO bilayer has the flexibility, wettability, and high surface energy of ITO, but is not brittle or expensive,” said Hongkyu Kang, a senior researcher at GIST. “This makes it easier to use ZnO for manufacturing organic solar cells and developing a printing technology for large-area solar cell technology.”

The new ZnO bilayer-based OSCs has an efficiency of 7.67% and a module area of 528 square centimeters. According to the researchers, this makes it the most efficient large-area OSC ever reported. They said the key to such power conversion efficiency was to reduce the “recombination” of charge carriers in OSCs by the crystalline ZnO nanoparticles. That also improved the open-circuit voltage.

They described their findings in “Overcoming the Low-Surface-Energy-Induced Wettability Problem of Flexible and Transparent Electrodes for Large-Area Organic Photovoltaic Modules over 500 cm2” which was recently published in Advanced Energy Materials. The research was the result of an industry-university collaboration, in which GIST developed the technology and transferred it to South Korean manufacturer MSWAY Co., Ltd.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.