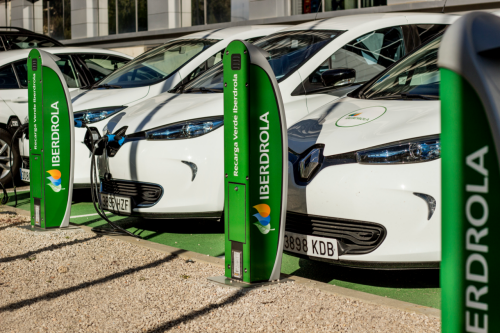

Iberdrola and bp have announced plans to form a strategic collaboration aiming to significantly expand fast EV public charging infrastructure and green hydrogen production. The partners have earmarked €1 billion for deploying up to 11,000 fast charge points across Spain and Portugal. The plan includes installing and operating an initial 5,000 fast charge points by 2025, and up to a total of 11,000 by 2030, including Iberdrola’s existing fast charging hubs. In addition, the companies also plan to form a joint venture for large-scale integrated green hydrogen production in Spain, Portugal, and the UK, as well as production of derivatives such as green ammonia and methanol, which could be exported to Northern Europe. The energy majors are aiming for up to 600 kilo tons per annum (ktpa) of hydrogen production capacity, integrated with new renewable power. “With this agreement, we continue advancing in the decarbonization and energy self-sufficiency through the electrification of two key sectors of our economy, transport and industry. The scale of this challenge requires alliances between companies such as Iberdrola and bp, which have the technology and knowledge necessary to help accelerate Europe's industrial development and generate, at the same time, well-being and new opportunities for all through clean energy,” said Iberdrola Chairman Ignacio Galan. Iberdrola and bp aim to finalize both joint venture agreements by end 2022, subject to regulatory approvals.

In a separate announcement, bp has pledged to invest up to GBP 50 million ($61 million) in its new global battery research and development center in Britain. Planned to open by the end of 2024, the new EV battery testing center and analytical laboratory will be located at bp’s existing global headquarters for its Castrol business in Pangbourne, Berkshire. The new facilities will aim to advance the development of fluid technologies and engineering for hybrid and fully battery electric vehicles. Used by a great number of car manufacturers today, bp’s trademark Castrol ON advanced e-fluids play a key role in managing temperatures within the battery, which enables ultra-fast charging and improves efficiency, helping EVs to go further on a single charge and extend the life of the drivetrain system. “The growth of EV fluids is a huge opportunity, and we aim to be the market leader in this sector,” Castrol CEO Michelle Jou said. “This significant new investment will now allow us to build additional strategic technologies and capabilities to further advance EV fluids for the future.” Previously, bp announced its intention to invest up to GBP 18 billion ($22 billion) in the UK’s energy system by the end of 2030.

California-based QuantumScape has built a prototype 24-layer solid state cell, up from 16 layers presented earlier this year. In its Q2 letter to shareholders, the company said that its 24-layer cell showed similar early capacity retention behavior to its single-, four-, 10- and 16-layer cells. “This is an important result because, as we have previously indicated, 24-layer cells represent A-sample candidates for some automotive OEMs,” the company said. Delivery of the A sample represents the beginning of the automotive qualification process, which involves several major delivery milestones — A, B and C samples — followed by the start of production. In the document, QuantumScape said it has agreements in place with six prospective automotive customers — “from global top-10 manufacturers by revenue to premium performance and luxury automakers, encompassing both pure EV and conventional OEMs.” To date, its main shareholder remains Volkswagen Group. QuantumScape added that the 24-layer cell is being tested in various formats, including a proprietary one in which some of its cells have achieved over 600 cycles and were still cycling. In addition, the company has reported advances in separator manufacturing and the implementation of its second-generation catholyte, which allows for discharging at ultralow temperatures of -30 C with good capacity retention. The company said it has also faced some challenges in its manufacturing processes, “from the discovery of a contaminant in our material to identifying defects introduced during the production process.” It said it has successfully addressed a number of these challenges while it continues to work through others.

Toyota Motor plans to invest IDR 27.1 trillion ($1.80 billion) in Indonesia in the next five years to produce EVs, Indonesia's economics ministry said on Wednesday. The Japanese carmaker has thus joined the likes of Hyundai Motor and LG Energy Solutions to announce big investments in the Southeast Asian country, which aims to become a global EV manufacturing hub. “I believe demand for EVs whether its four-wheels or two-wheels will keep increasing in Indonesia and ASEAN,” said Indonesia's chief economics minister, Airlangga Hartarto, after a meeting Toyota's Vice Chairman Shigeru Hayakawa last week. Earlier last week, Indonesia also announced that Mitsubishi Motors planned to invest about IDR 10 trillion in Indonesia between 2022 and 2025 to produce hybrid and battery EVs.

Dutch solar car company Lightyear has welcomed Swedish manufacturer Koenigsegg as a development partner and investor. Under the technology-sharing partnership, the two automakers will share proprietary and patented information to enable the development of ultra-efficient vehicles and jointly develop new automotive technologies. Specifically, Koenigsegg's technologies will be applied to further improve the energy efficiency of Lightyear’s second model, Lightyear 2, slated to enter production in late 2024 or early 2025. Lightyear 2 is to be available as a mass-market model at prices starting at 30,000 euros, the Dutch company previously announced. The announcement of a new partnership comes only weeks after Lightyear launched the final design of its long-range, production-ready solar car. The model, which has been renamed “Lightyear 0,” has a Worldwide Harmonized Light Vehicle Test Procedure (WLTP) range of 625 kilometers and consumption of 10.5 kWh per 100 kilometers. However, the Dutch startup claims that a theoretical range of 695 kilometers could be achieved, with a battery pack capacity of 60 kWh. “The optimized solar roof and holistic design mean that the car can drive for weeks, even months, without charging,” the company said.

Stellantis has seen global sales of BEV vehicles increase by almost 50% year-on-year to 136,000 units in the first half of 2022. Among all its brands, the group offers 20 fully-electric vehicles and it plans to increase that number to 28 vehicles in the next two years. The company achieved record profitability with an adjusted operating income (AOI) margin of 18.1%. In North America, Stellantis said it “achieved record profitability” in the past six months, pointing to the strong early uptake for the Jeep Wrangler 4xe, which is now said to be the best-selling plug-in hybrid in the US. Stellantis’ H1 2022 AOI margin for Europe was 10.1%, while its European Union EV market share went down to 21.2% from the previously reported 22.9 percent. Among BEV vehicles, the new Fiat 500 electric sold best in Germany and Italy, while in France it was the Peugeot e-208. The group also reiterated its plan to build three gigafactories in Europe with the help of Automotive Cells Company, Samsung SDI and LG Energy Solution, as well as two more in North America.

Battery cell manufacturer Britishvolt has received confirmation from the British government that it is to receive funding to support its plan to build a battery cell gigafactory in Northumberland. “I’m delighted to confirm we have now provided Britishvolt with a final grant offer through the Automotive Transformation Fund,” UK Business Secretary Kwasi Kwarteng is quoted as saying in the company’s announcement. “The Blyth gigafactory will turbocharge our plans to embed a globally competitive electric vehicle supply chain in the UK and it is fantastic to see how the project is progressing.” The total investment for Britishvolt’s Blyth Gigafactory stands at around £3.8 billion ($4.6 billion), with the overwhelming majority coming from private sources. At full production, the factory will crank out enough cells for more than 300,000 lithium-ion batteries a year. The facility is expected to employ more than 3,000 people directly and another 5,000 in the wider supply chains. In a separate announcement last week, Britishvolt said it had signed a memorandum of understanding with Beijing-listed BTR for the supply of synthetic graphite and silicon oxide. The anode material supplied by BTR will be exclusively processed by hydropower and thus contribute Britishvolt’s sustainability efforts.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.