From pv magazine USA

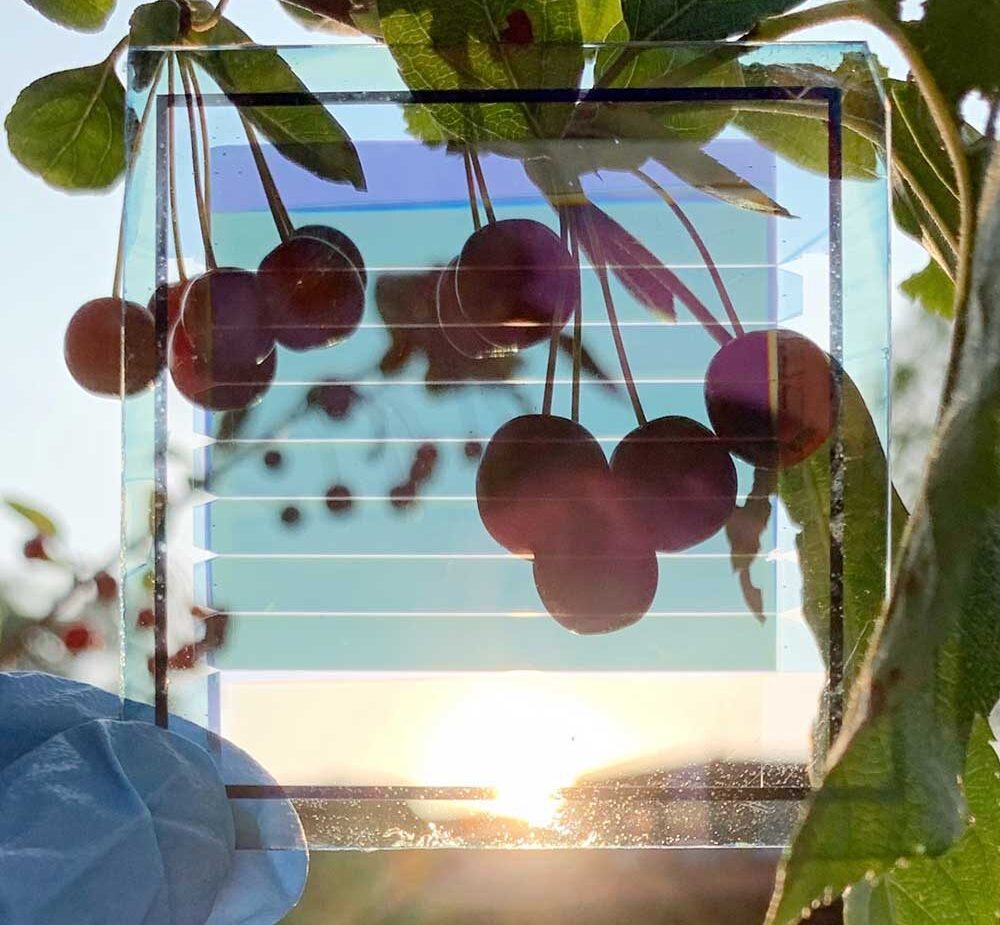

University of Michigan researchers announced in a Joule magazine post that they have achieved a new technique for manufacturing efficient semitransparent solar cells. The cells are intended to be built inside panes of window glass, turning passive buildings into active energy producers.

Organic solar cells can be transparent, unlike their opaque counterparts in traditional silicon-based solar cells. Silicon cells are widely used for their durability and efficiency advantages, but recent advances from the Michigan lab have achieved efficiencies of around 10% and estimated lifetimes of up to 30 years in organic solar cells.

The team set forth to make the semitransparent cells manufacturable at scale. A key hurdle was creating the micron-scale electrical connections between individual cells that comprise a solar module. Conventional methods use lasers for this patterning process, but the laser would cause damage to organic light absorbers.

The solution the Michigan team arrived at is a multi-step peel-off patterning method that achieves micron-scale resolution. Thin films of plastic are deposited and patterned in extremely thin strips. Then the organic material and metals are layered in. Finally, the researchers peel off the strips, creating very fine electrical interconnection layers between the cells.

In the process, eight semitransparent solar cells were connected, each 4 cm x 0.4 cm and separated by 200µm-wide interconnections, to create a single 13 cm squared module. The achieved module achieved an efficiency of 7.3%, about 10% less than the individual cells. This material is 50% transparent, making it a good fit for commercial windows. Higher transparency is likely needed for the residential market, though the researchers said that is easy to achieve with organic solar cell material.

The team said its goal is to develop a 50% transparent cell with 10% to 15% efficiency, which Michigan professor Stephen Forrest said will likely be achieved within a few years. “The research we are doing is derisking the technology so that manufacturers can make the investments needed to enter large scale production,” he said. “In principle, we can now scale semitransparent organic solar cells to two meters by two meters, which brings our windows much closer to reality.”

Buildings account for about 40% of global carbon emissions. Buildings-integrated photovoltaics (BIPV) like this technology under development are an effective way to bring energy production closer to the point of demand, mitigating the amount of grid infrastructure that needs to be built to support the building’s needs.

The University of Michigan has applied for patent protection and is seeking partners to bring the technology to market. The research was supported primarily by the US Department of Energy, as well as by Universal Display Corporation.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.