Scientists at Sungkyunkwan University (SKKU) in South Korea have developed a busbar-free solar cell design for shingled solar modules to reduce silver (Ag) paste consumption. They designed the cell with a busbar-free electrode pattern, with the electrodes consisting of Ag fingers and busbars on the front side and aluminum (Al) electrodes and Ag busbars on the rear side.

“The new electrode pattern is expected to significantly reduce the manufacturing cost of high-density shingled photovoltaic modules,” researcher Jaehyeong Lee told pv magazine.

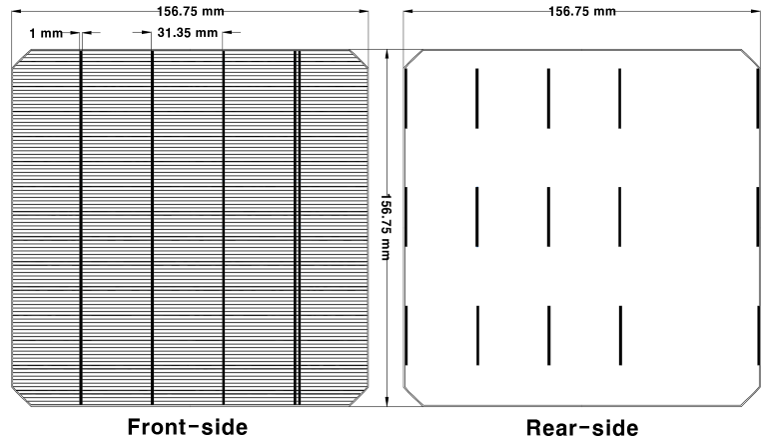

The fingers collect the current from the front side of the solar cell and the current flows to the busbar, where it can flow to the outside circuitry. On the cell's rear side, the Al electrode moves the current to the silver pad, and the current can then flow through the soldered metal ribbon. The cell measures 156.75 mm × 156.75 mm and relies on 100 fingers, each with a width of 50 μm.

“The conventional electrode pattern has five front and rear busbars, each with a 1 mm width, while the cost-efficient design has no busbar,” the researchers said.

They used laser scribing and mechanical breaking to assemble the cells in cell strips and an electrically conductive adhesive from German manufacturer Henkel to bond the cells in strings, with each string containing 15 cell strips.

“The cell strips at both edges of the string have a pattern with busbars since the shingled string should be interconnected to manufacture a PV module,” they said, noting that the shingled strings were connected to each other via a tabbing and busing process. “The manufacturing method is the same as that of the conventional module, except for the laser scribing and ECA bonding processes to produce a shingled string.”

The research team assembled the strings in an experimental laminated and framed shingled PV module. After a series of measurements, they found that its performance was almost the same as that of a reference shingled panel built with a conventional cell design.

“The difference in the output power between the two types of modules is only 0.5 W, which could be negligible given the measurement error range,” they said, adding that the main advantage of the busbar-free cell is a 61.33% reduction in silver consumption.

The South Korean group described the cell design in “Busbar-free electrode patterns of crystalline silicon solar cells for high density shingled photovoltaic module,” which was recently published in Solar Energy Materials and Solar Cells. “The most important advantage of the busbar-free electrode pattern presented in this work is the cost reduction,” they said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.