From pv magazine Germany

Germany's Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and Augsburg-based TubeSolar AG have achieved a power conversion efficiency of 14% for a perovskite-based photovoltaic film that TubeSolar developed.

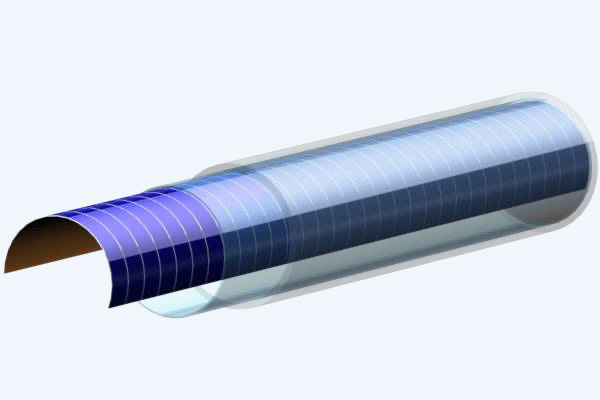

TubeSolar uses the flexible photovoltaic film for its lightweight thin-film solar modules encapsulated in a glass tube. It said the film was fabricated with a roll-to-roll technology and slot-die coating, which is a coating process used for depositing thin and uniform films with limited material waste and low operational cost.

“The speed of the coating process was over one meter per minute,” the manufacturer said. “The partners' objective is to transfer the high efficiencies currently achieved in research on small areas to larger solar films and thus to commercialize slot die deposition as an industrially suitable coating method for flexible perovskite solar cells. By further optimising the solar cell layer stack and the absorber as well as the conductivity of the electrodes, the technology can be significantly improved even further.”

It said its products can be permeated by light and water for optimal plant growth and require simple, inexpensive mounting and assembly. The tubes offer partial shading to crops, as well as protection from heavy rain, hail and bird droppings. Tube Solar says their rounded surface also offers a self-cleaning aspect.

Tube Solar aims to expand its annual production capacity at Augsburg to 250 MW. The factory belonged to German multinational lighting company Osram, which previously owned some shares of the patent for TubeSolar's panels.

TubeSolar increased its share capital from €12 million ($12.2 million) to €13.2 million by issuing more shares in June.

“The expected proceeds from the capital increase are to be used to finance the further growth of TubeSolar AG and in particular for investments in the development of the highly automated production of TubeSolar photovoltaic modules,” it said at the time.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.