Scientists in Germany have conducted a life-cycle analysis of perovskite-silicon tandems to determine how this new technology could affect the sustainability of the energy supply and solar manufacturing itself.

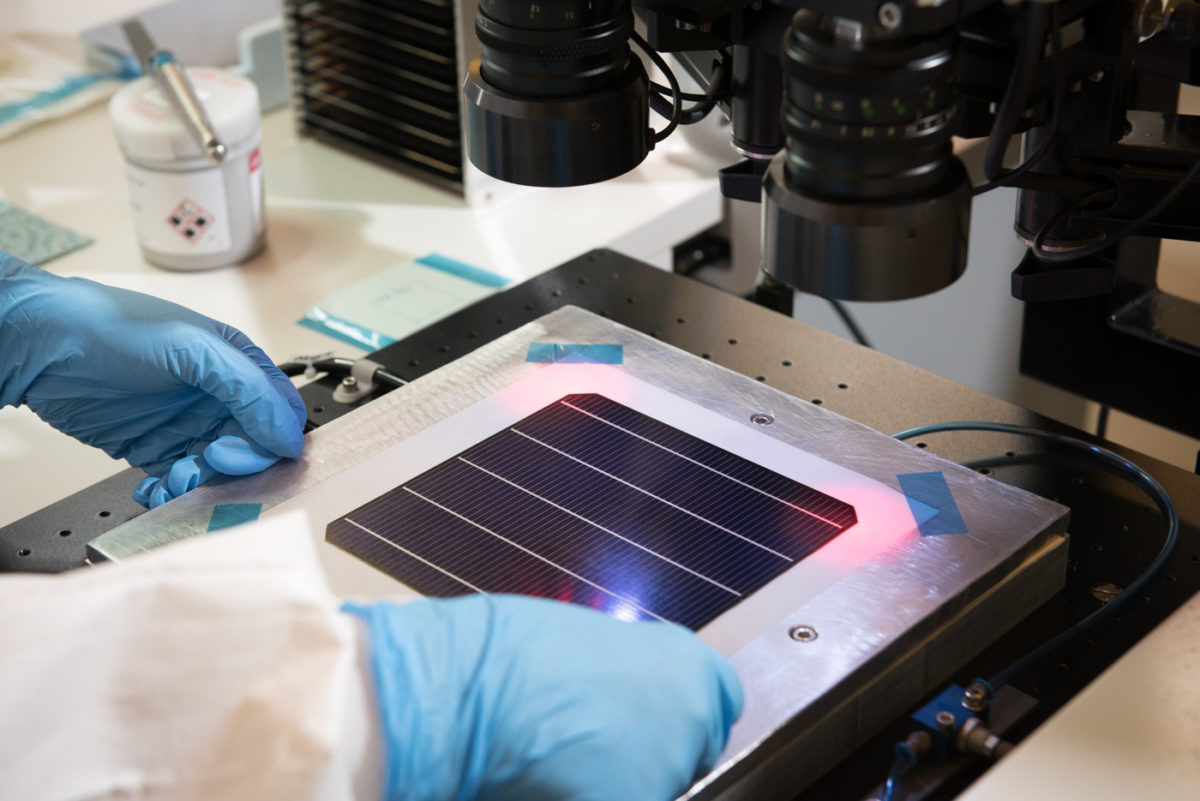

The study focuses on materials and manufacturing processes provided by Oxford PV, which is currently ramping up commercial production of perovskite-silicon modules in Germany. It is the first to analyze the environmental impacts of perovskite technology based on actual industrial production data.

Tandem cell manufacturing starts with the processing of silicon solar cells, and then adds a second active cell layer on top. So naturally, with more manufacturing involved, the impact increases. However, the scientists found that the additional energy required to manufacture a tandem module could be more than offset by the extra energy it will produce over its lifetime.

“We found that the perovskite-on-silicon module has 6% to 18% less environmental impact than a silicon module, when we consider the additional energy generated over the tandem module’s 25-year lifetime,” said Martin Roffeis, co-author from Technische Universität Berlin.

The gap will presumably get larger as the technology improves, as another group of researchers recently passed the 30% efficiency mark with a tandem cell. The full analysis can be found in “New insights into the environmental performance of perovskite-on-silicon tandem solar cells – a life cycle assessment of industrially manufactured modules,” which was recently published in Sustainable Energy & Fuels.

The group found that the impacts of the tandem modules were up to 7% higher in the categories of global warming potential, terrestrial ecotoxicity, freshwater consumption, fossil fuel depletion, and metal depletion. The tandem module in the study was shown to generate the same amount of electricity in 22 years as reference silicon heterojunction module over 25 years, which was enough to offset these extra impacts. While the addition of perovskite to the module was shown to increase its environmental impacts, the study also showed that the largest part of these impacts came from the manufacture of the silicon wafer – this stage showed the largest impact in global warming potential, freshwater consumption, and fossil fuel depletion.

In the remaining categories of ecotoxicity and metal depletion, the production of copper cabling, aluminum module frames, and float glass were shown to be the largest contributors. The researchers said that the use of lead in the perovskite layer, which is controversial to some due its toxicity, actually had very little impact on the ecotoxicity score.

“The sustainability of solar materials and supply chains is growing in importance as the world deploys solar at the multi-terawatt level,” says Laura Miranda Pérez, head of materials research at Oxford PV.

“We hope our contribution will help industry and the wider scientific community to improve the design, production, and end-of-life management of tandem technologies, supporting their rollout,” she added.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.