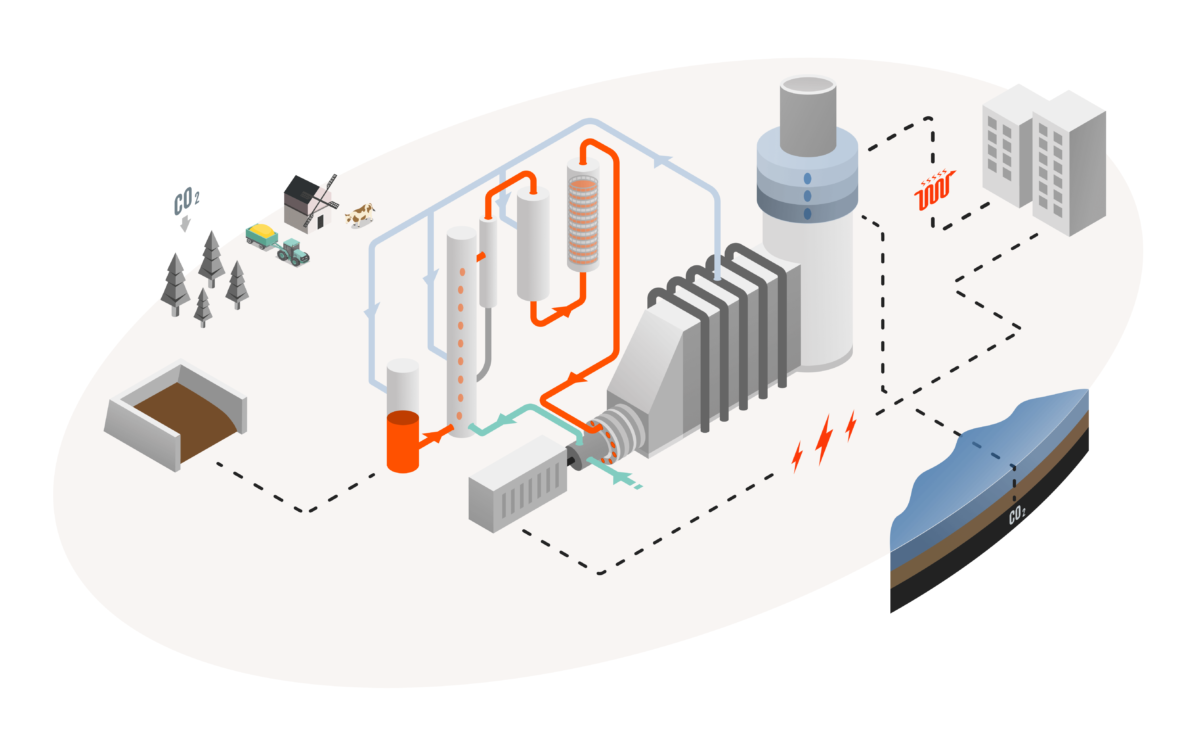

Bio-FlexGen is testing a four-mode plant that produces heat, electricity, hydrogen and biogenic CO2. The team of 14 partners and five EU countries is working to integrate a new heat and power plant (CHP) primary fueled by forestry residues, with the addition of a hydrogen production-storage-consumption system.

The European consortium aims to launch the first plant’s commercial operation in 2030. It is exploring two sizes. The small one would have 50 MW of fuel input, 25 MWh of electricity, and a hydrogen capacity of 34 MW, or 960 kg/hour. The biggest facility could reach 300 MW of fuel input, 150 MWh of electricity, and a hydrogen capacity of 192 MW, or 5,760 kg/hour.

The plant could use forestry, agricultural and demolition waste streams to produce power, heat, and hydrogen. The latter could then be stored for days or weeks, whereas the carbon dioxide could be permanently removed. Energy prices, hydrogen prices, and demand for heat will be the three main factors defining a plant’s operating mode.

“Bio-FlexGen plants don’t necessarily have to be close to wind and solar installations. But they should be in the region. It should be suitable to have these plants in the same electricity grid area,” Henrik Båge, the CEO of Stockholm-based Phoenix BioPower, told pv magazine.

Båge said the plants will be distributed. They will be close to large renewable facilities, as well as large consumers of syngas and hydrogen, like steel producers and refineries. Low-carbon steel initiatives in Sweden are expected to require large quantities of electricity, amounting to around 50% of the country’s current electricity consumption.

“Bio-FlexGen can supply electricity, but also hydrogen from forest waste streams. We can decouple the price of hydrogen from the price of electricity to a very large extent, by using biomass that comes at a very stable cost and flow, as it is a waste from the Swedish and Finnish forestry industry,” said Båge.

The project provides hourly, daily and seasonal flexibility. Stored hydrogen from the plant’s storage or hydrogen brought through an external pipeline can be used to start the gas turbine-based power generation within an hour when the power is needed quickly.

The plant can adapt the biomass feedstock to power consumption needs within two hours to provide daily flexibility. Seasonal flexibility relies on the fact that the plant can produce power and heat when the heat demand and electricity prices are high, while producing hydrogen and syngas in summer.

The plants could also participate in the ancillary services market, said Båge, adding that this technology became even more relevant after the Russian invasion of Ukraine, given the industry’s need to replace Russian gas while refraining from coal consumption increases.

“In the EU and the UK, there is enough biomass to produce more than double the electricity that produced from Russian gas in the EU,” said Båge.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.