Researchers from the Uppsala University in Sweden have fabricated a silver-alloyed copper, indium, gallium and selenium (ACIGS) thin-film solar cell relying either on indium tin oxide (ITO) transparent back contacts or hydrogen-doped indium oxide (IOH). “The cell can be used as top cells in four-terminal tandem devices,” the research's corresponding author, Jan Keller, told pv magazine. “For a two-terminal configuration, the bandgaps are too low. For this, a bandgap of at least 1.55 eV is needed.”

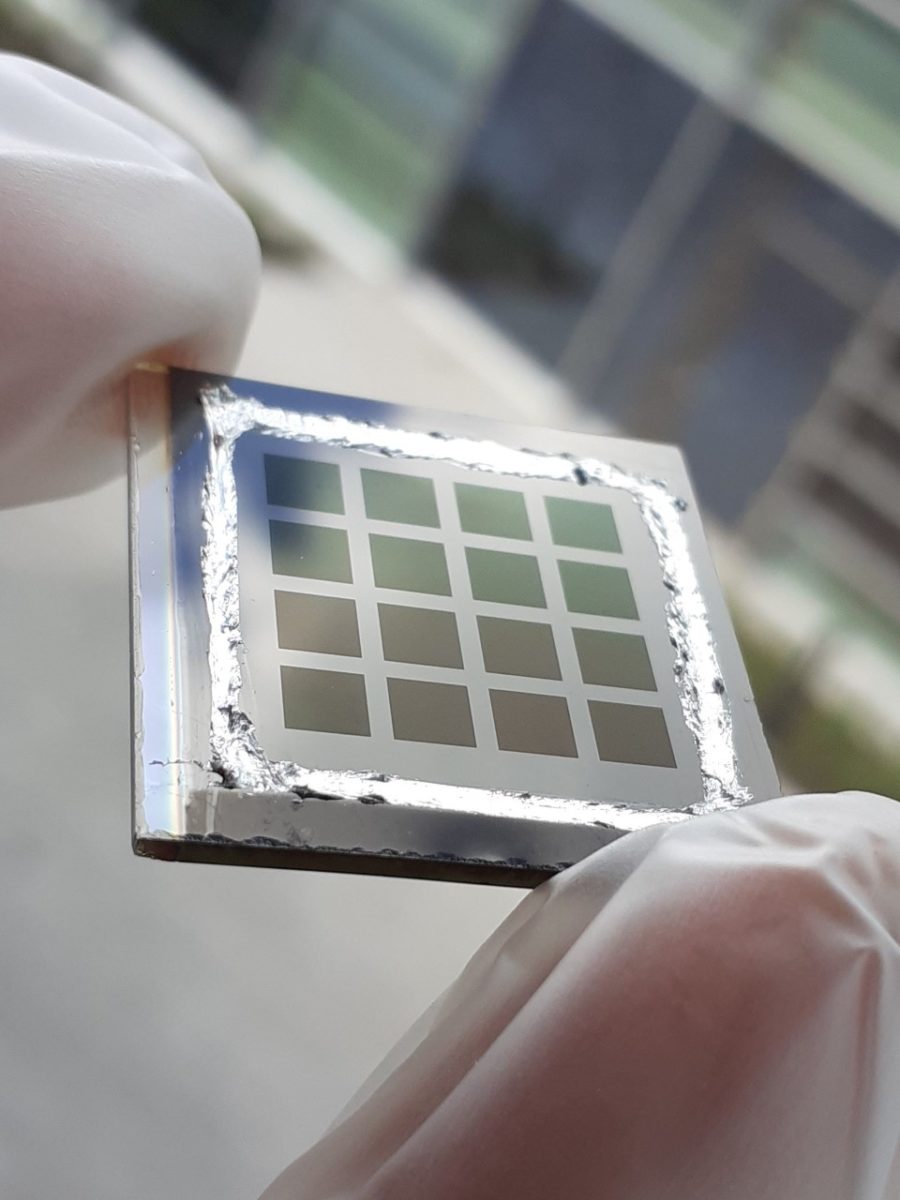

The scientists built the cell using a three-stage co-evaporation technique and a high-temperature absorber deposition process. They also utilized cadmium sulfide (CdS) for the buffer layer, ITO and IOH contacts with a thickness of 180/310 nm, and silver alloying to increase the absorber bandgap energy.

As conventional transparent back contacts (TBCs), ITO contacts may cause the formation of gallium oxigen (GaOx) at the TBC/absorber interface, which is detrimental to the cell's fill factor. “ITO forms a similar amount of GaOx as IOH,” Keller emphasized. “What we found is that a fine-tuning of the sodium fluoride (NaF) supply, as well as using stoichiometric absorber composition, enables high fill factor values and most likely mitigates GaOx formation.”

“The ITO films used in this study effectively block sodium (Na) diffusion from the substrate, according to glow-discharge optical emission spectroscopy (GDOES) measurements,” the researchers highlighted, noting that the origin for the increased sodium sensitivity for the ACIGS solar cell remained unclear.

The ACIGS cell with a band gap of 1.44 eV and with the ITO contacts achieved a power conversion efficiency of 10.4%, an open-circuit voltage of 817 mV, a short-circuit current of 19.3 mA cm2, and a fill factor of 63.4%. The same device with the IOH contacts reached an efficiency of 12.0%, an open-circuit voltage of 835 mV, a short-circuit current of 22.1 mA cm2, and a fill factor of 65.2%.

For comparison, a reference CIGS cell without silver with ITO contacts achieved a power conversion efficiency of 11.2%, an open-circuit voltage of 828 mV, a short-circuit current of 19.8 mA cm2, and a fill factor of 68.0%. The same device with the IOH contacts reached an efficiency of 10.5%, an open-circuit voltage of 828 mV, a short-circuit current of 18.6 mA cm2, and a fill factor of 67.9%.

“An efficiency of 12% is reached for the best cell with an IOH back contact,” the academics stated. “This is the highest reported value for a wide-gap chalcopyrite solar cell on a TBC. In addition, a very high infrared transparency is possible, due to the negligible free charge-carrier absorption (FCA) of the IOH (compare Figure 6) and the absence of an interlayer to improve the electronical properties of the contact.”

“We plan to try fabricating these devices in superstrate configuration in the future, which requires the usage of thermally stable buffer layers. In this way, only one glass sheet is needed, which would reduce the costs in a final module,” Keller further explained, adding that efficiency of up to 18% would be required to help the device reach commercial maturity.

The researchers presented the cell in the paper “Wide-Gap Chalcopyrite Solar Cells with Indium Oxide–Based Transparent Back Contacts,” published in RRL Solar.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.