A series of PV market, technological, macroeconomic, and even geopolitical developments have coalesced to make the automation of solar O&M provision a compelling proposition in 2022. In a recent pv magazine webinar, Wood Mackenzie Principle Analyst Daniel Liu described O&M automation as, “one of the last few places to unlock additional cost efficiencies on a project.”

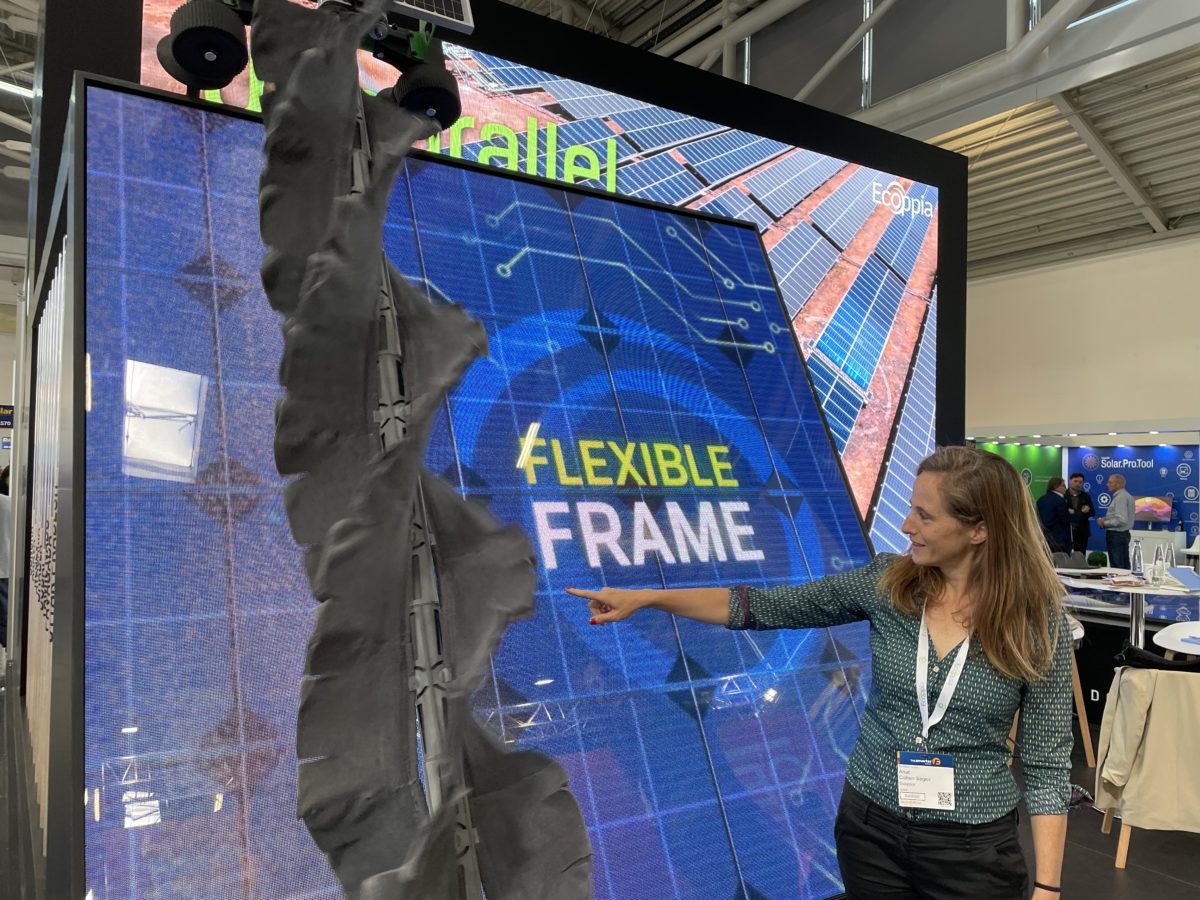

The webinar was delivered in partnership with robotic cleaning provider Ecoppia, and the company’s CTO Ziv Ramati Miller noted that with two years of Covid-19 lockdowns making site visits at times impossible, automated O&M became the only way production, and profitability, could be maintained.

“It was only on sites that were fully automated that production was allowed to continue almost the same,” said Ramati Miller. “You needed to implement automation just to stay where you are.”

Given the imperative to adopt automation in O&M, pv magazine has partnered with Ecoppia to conduct a first-of-its kind survey into the subject. The short survey has been designed to take less than five minutes to complete, and constructed to reveal insights into the opportunities for automation in O&M and potential impediments to its more widespread adoption.

Complete the survey to influence how automation will be employed in O&M provision today and into the future.

While O&M may not be the first item on a project developer’s agenda, the webinar presenters agreed that how plants are to be maintained should be considered in the early development stages.

“It is true that solar is a very simple and robust technology, but we must keep in mind that your project starts with the early development phase and sometimes we tend to overlook some key considerations,” said Nicolas Chouluer, a partner at Europe-based independent engineers Everoze. “Good maintenance will help keep your asset viable.”

Inside automation

In terms of good maintenance, Ecoppia CTO Ramati Miller argued that technological development has delivered a host of opportunities for O&M automation. And in the current solar market, it is “not only a possibility but a necessity.”

“You really have to combine the data from all sources, and it is not just about solar panel cleaning, but infrastructure, and corrective maintenance. If you can tell in advance which panels need to be switched, then you don’t need to have people on site constantly monitoring the situation. But you need to combine all of these [data] sources.”

Ramati Miller outlined how it is possible today to equip robotic cleaners with a host of sensors that can collect detailed information on module health – and importantly how things develop over time. With robots passing over modules on a regular basis, their ability to collect data in an ongoing fashion is unparalleled, he said.

“There are a lot of options for what can be fitted to a robot,” said Ramati Miller. As an example, he explained how simple sensors can monitor a tracking system’s health.

“One of the most basic situations we offer is just [to monitor] the angle of the panels. When we measure that we can see if angle keeps changing on trackers. Usually, you have a sensor in the middle of a row, at the motor, which might cover two tables. But the angle at the corners might change, and just by monitoring the angles in the corners it lets you know about material fatigue.”

In terms of the size of the opportunity, Wood Mackenzie’s Daniel Liu explains that given the current size of the installed PV fleet, “as a rule the industry needs to be much more proactive about all O&M and in this module washing.” He said that WoodMac anticipates annual non-residential solar O&M spend to reach $15 billion by 2030.

“Automation should ultimately help asset owners identify the true site conditions and give people a better handle on what is needed,” said Liu. “Predominately we have seen that degradation is much higher and one of the main reasons why due to soiling losses being higher than expected – even in places where you would expect rain to be quite frequent.”

The survey results will be presented and analyzed in the pv magazine Global magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.