From pv magazine Germany

German chemicals producer Evonik Industries has launched a new processing additive portfolio for solar wafer cutting.

The new Tego Surten E product is designed to improve the performance of solar wafer cutting. Evonik wanted to publicly present its new product at the SNEC in Shanghai, which has now been postponed to the end of the year due to the pandemic in China.

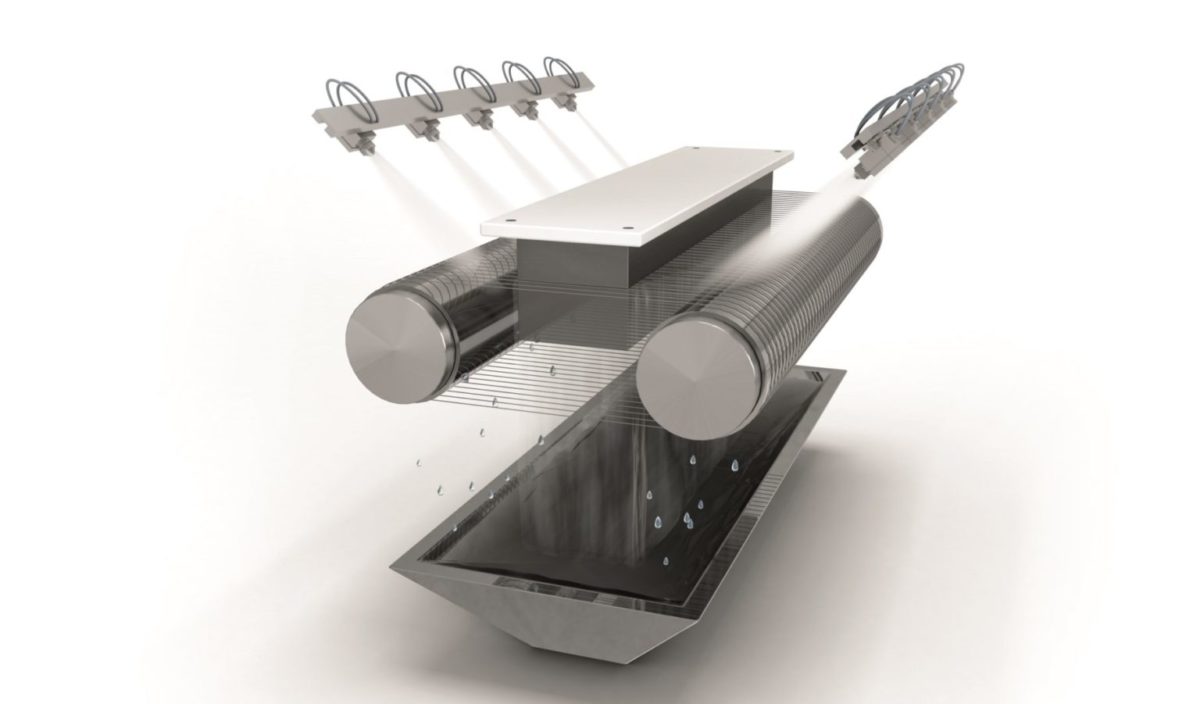

According to the manufacturer, the new additive series can achieve a significantly better cut quality ratio at higher cutting speeds and smaller wire diameters on large wafers (M12), resulting in cheaper post-processing work for sliced wafers. Increasing the power when cutting the wafers leads to better overall performance and production efficiency of the solar modules, said the company.

Conventional cutting fluids with standard surfactants do not meet the requirements of the latest high-performance cutting process. Products developed with these fluids show deep cut lines and divots, which are caused by ineffective swarf transport and degradation of the wire's diamond coating. This lowers wafer quality and can also lead to the formation of large crystals during the subsequent diffusion step, which ultimately reduces cell efficiency.

The wetting agents and defoamers in Tego Surten E contain the right balance of extremely low dynamic surface tension and adhesion tendency to effectively remove cutting chips.

“These low-dose additives can significantly improve the quality and speed of cutting photovoltaic wafers and thus contribute to another step on the way to a climate-neutral future,” said Benjamin Brehmer, global segment manager energy and storage for Evonik’s interface and performance business line.

Module manufacturers could also use the additive portfolio in many emerging PV applications. For example, it could be used to support more uniform and improved anti-reflective and reflective coatings, as well as other engineered surface modifications that improve the overall energy output of solar applications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.