Researchers at the Pabna University of Science and Technology in Bangladesh have simulated a heterojunction thin-film solar cell based on a tin sulfide (SnS) absorber at low production costs.

“Our cell could be used in thin-film modules with potential applications in either ground-mounted and rooftop PV projects,” the research's corresponding author, Aadnan Hossain, told pv magazine. “SnS is earth-abundant, toxic-free, thermally stable, and cost-effective, and it has a suitable bandgap of around 1.3 eV and a high absorption coefficient of over 104 cm-1.”

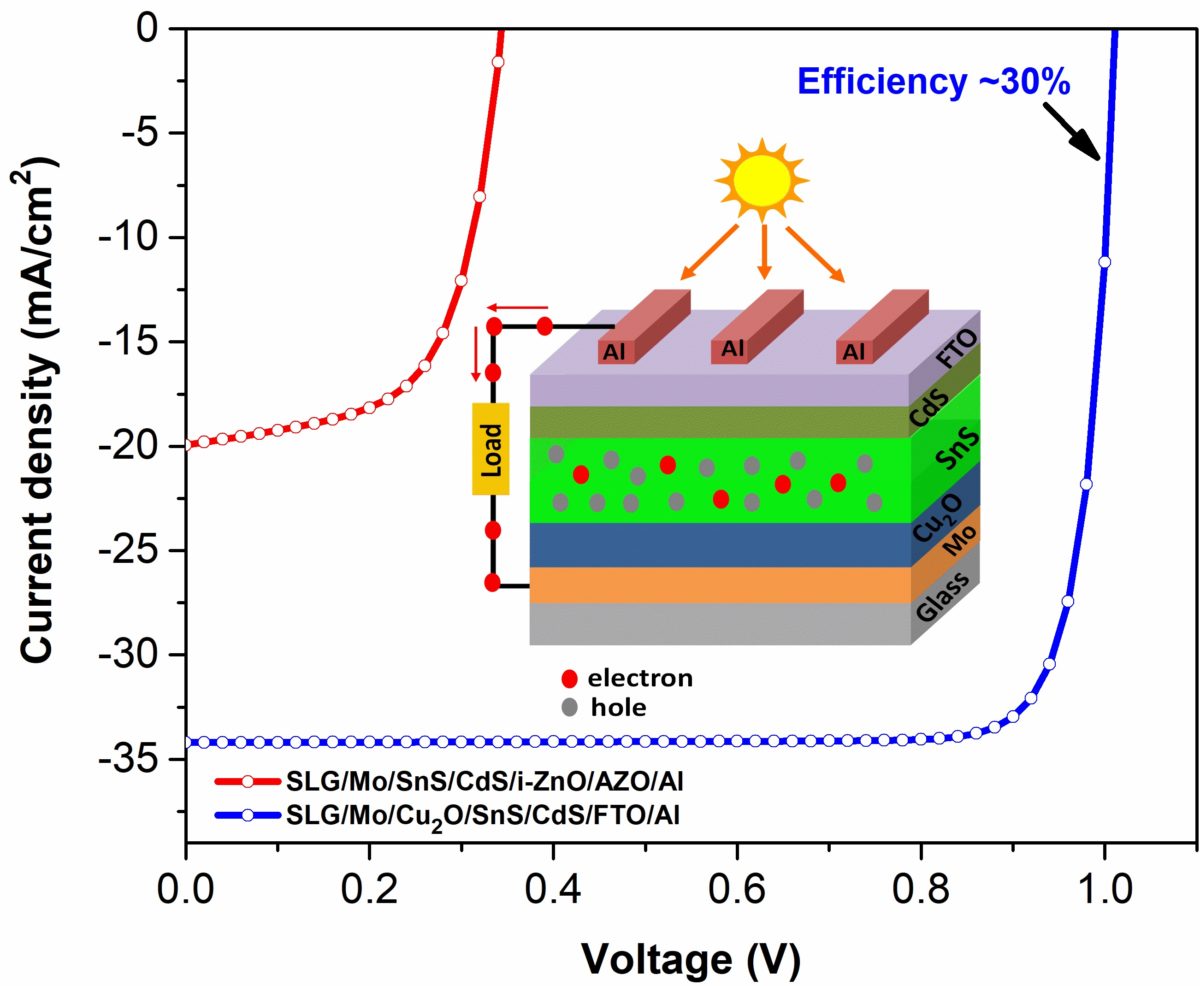

The solar cell was designed with a molybdenum (Mo) layer, a hole transport layer (HTL) based on copper(I) oxide (Cu2O), a tin sulfide absorber, a buffer made of cadmium sulfide (CdS), a transparent conducting window layer made of fluorine-doped tin oxide (FTO), and an aluminum (Al) back contact. In this cell configuration, the HTL is attached at the back of the SnS layer.

The proposed SnS-based PV device structure was analyzed via SCAPS-1D, which is a simulation tool for thin-film solar cells developed by the University of Ghent in Belgium.

“All the values were calculated and verified for different layers to make the cell stable and realistic commercially,” Hossain explained. “Moreover, thickness and doping density were kept low at the SnS absorber layer which reduces the fabrication and production cost.”

The scientists found that thicknesses of 0.1 μm, 1 μm, 0.05 μm, and 0.05 μm should be achieved for the Cu2O HTL, the SnS absorber, the CdS buffer, and FTO TCO, respectively. With these parameters, the cell should be able to reach a power conversion efficiency of 29.68%, an open-circuit voltage of 1.01 V, a short-circuit current of 34.19 mA/cm2, and a fill factor of 85.74%.

“These results suggest that the p-type Cu2O material can be employed as a potential HTL in the SnS-based heterojunction solar cell,” the scientists said.

They presented their findings in “Performance analysis of SnS solar cell with a hole transport layer based on experimentally extracted device parameters,” which was recently published in the Journal of Alloys and Compounds.

“The cell we designed and proposed does not require highly sophisticated equipment but a simple solution process which makes the reliable commercial production at a higher rate,” Hossain concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.