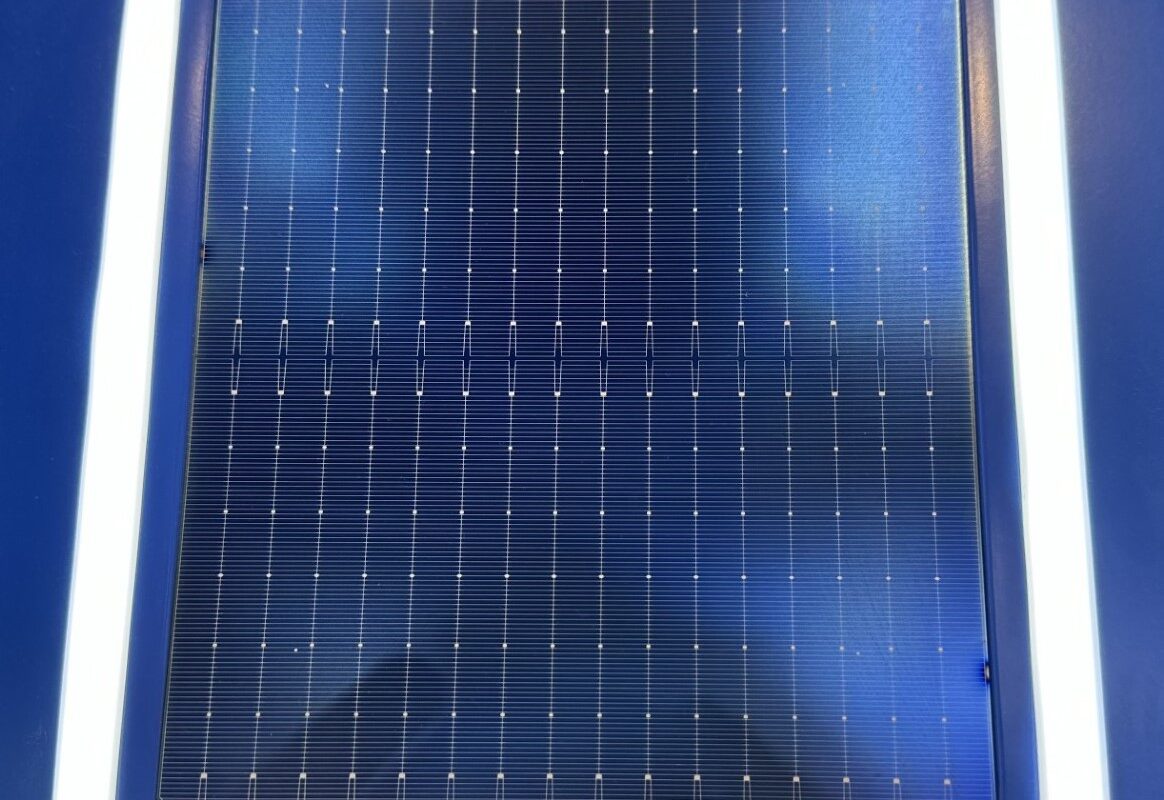

An international research team has developed a low-temperature planar perovskite module with an n–i–p architecture, an aperture area of 11 cm2, and a geometrical fill factor of 91%.

“With this work, we show that the scaling-up of high efficient perovskite solar cells to modules is possible without penalizing the efficiency and keeping the hysteresis index low,” researcher Aldo di Carlo told pv magazine.

The manufacturing temperature never exceeds 150 C. This represents an additional step to the industrial exploitation of perovskite photovoltaic technology.

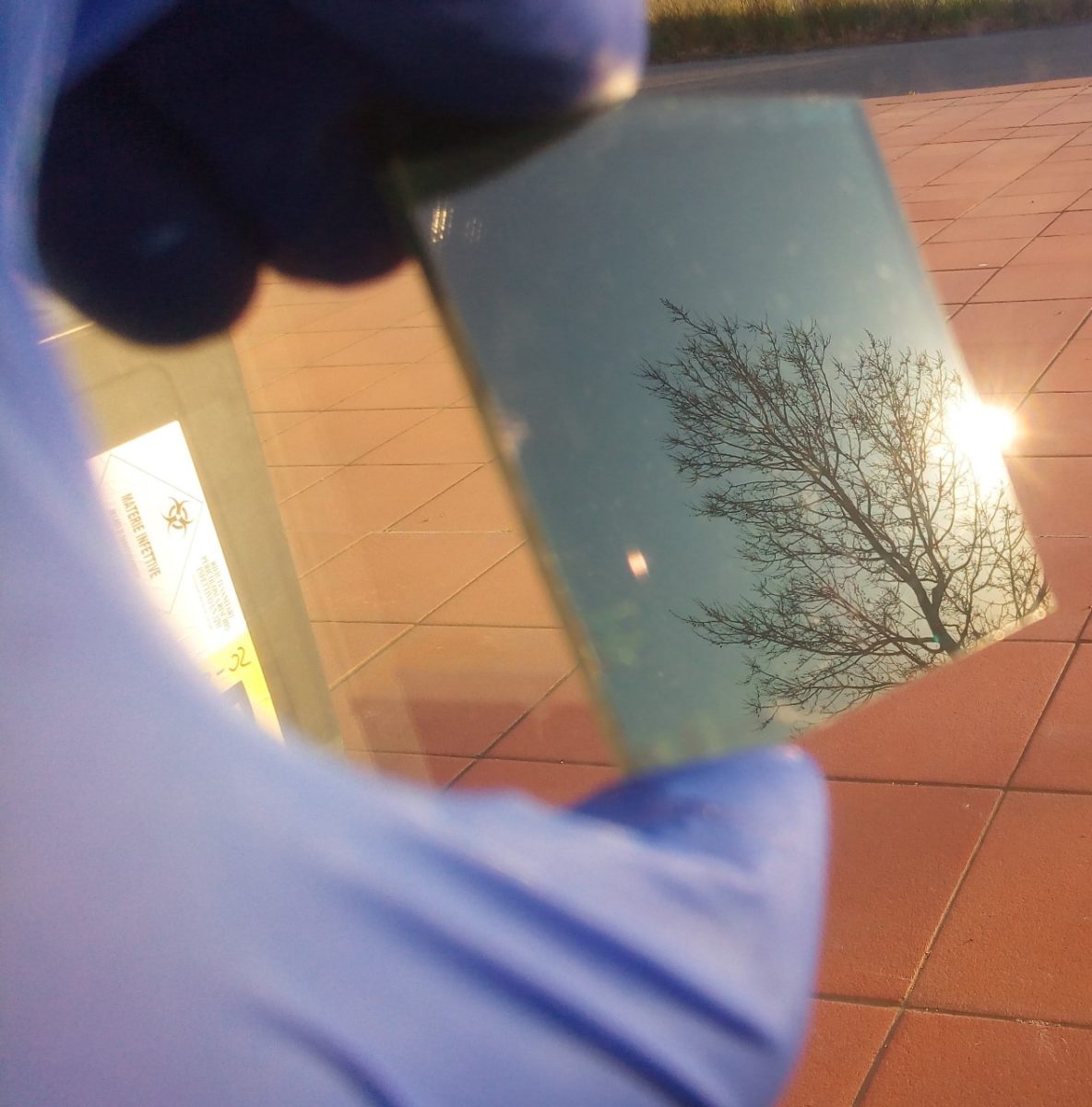

The module was built with 0.09 square-centimeter solar cells. The perovskite solution was deposited at 2,000 rpm with 10 seconds ramp-up to fully cover the substrate without persisting at this speed to prevent the dimethyl sulfoxide (DMSO) solvent from sticking onto the substrate.

“This is avery crucial point, because DMSO was trapped during film formation and formed voids at perovskite-substrate interface, as it has been recently demonstrated for a different p–i–n architecture,” the scientists said. “Moreover, to avoid cracks on the perovskite film, it is very crucial that the velocity of the antisolvent dripping and the distance between substrate and pipet tip.”

The solar module achieved a maximum power conversion efficiency of 19.11% and a stabilized efficiency of 18.7%.

“The reported simple and reproducible method represents an outstanding baseline to be transferred to large-area modules (size ≥100 cm 2 ) by scalable full fabrication procedure out of glove box,” the researchers concluded.

They described their design in “Hysteresis-free Planar Perovskite Solar Module with 19.1% Efficiency by Interfacial Defects Passivation,” which was recently published in RRL Solar. The research group includes scientists from the University of Tor Vergata in Rome, Belgian research institute Imec, and the Swiss Federal Institute of Technology Lausanne (EPFL).

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.