A team of researchers from The University of Queensland (UQ) has designed an atomic-thin cathode material that reduces corrosion in lithium-ion batteries and has demonstrated improved high-voltage cycling stability with capacity retention of almost 80% after 1,000 cycles.

Prof. Lianzhou Wang said he and his team from the School of Chemical Engineering and Australian Institute for Bioengineering and Nanotechnology (AIBN) have demonstrated a rechargeable lithium-ion battery which remains stable for more than 1,000 cycles.

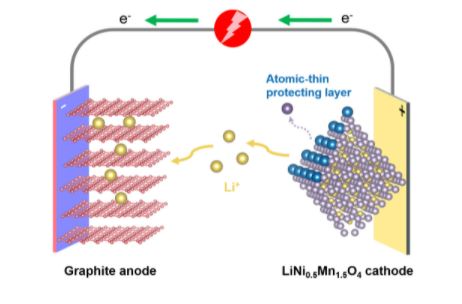

“We’ve designed a uniquely-grown atomic-thin functional layer on the surface of a high-voltage cathode, which is the source of lithium ions and a critical aspect that limits the cycle life in a battery,” he said. “This new approach features a minimal protective coating at a scalable process, paving the way for the deployment of these abundant high-voltage materials for next generation high energy batteries.”

Wang said corrosion in one form or another is the primary reason that batteries degrade but the new process would increase the life-span of batteries in everything from smart phones to electric vehicles (EVs).

The new technology involves the application of an epitaxially-engineered wetting layer on a lithium nickel manganese oxide (LNMO) cathode material. The research team said the atomic-thin wetting layer offers long-term suppression of the transition metal dissolution from the cathode without impacting its dynamics.

Wang said when tested in full lithium-ion coin cell configuration the coated LNMO, in combination with a graphite anode and a non-aqueous electrolyte solution, enables a capacity retention of about 77% after 1,000 cycles at 290mAg−1 and a final discharge capacity of about 80mAhg−1 with an average coulombic efficiency (CE) >99%.

Wang said with industry under increasing pressure to decarbonise, the development of lithium-ion batteries of lower cost, higher energy density and longer cycle life is vitally important.

“We’re confident the nanotechnology will have widespread applications across industry, including in consumer electronics, electric vehicles and the energy storage sector,” he said.

Dr Rosalind Gummow, technical specialist with Brisbane-based company VSPC, which is focused on developing and commercialising advanced cathode materials for lithium-ion batteries, welcomed the development.

“New methods like the use of epitaxial surface layers to improve the cycling efficiency and cycle life of high-voltage cathodes are vital in the quest to improve the energy density of Li-ion batteries,” she said. “The methods developed here also have potential to stabilise other cathode materials that degrade rapidly with cycling.”

The scientists explained their findings in “Epitaxial growth of an atom-thin layer on a LiNi0.5Mn1.5O4 cathode for stable Li-ion battery cycling,” which was recently published in Nature Communications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Lithium-ion batteries are the most common type of rechargeable battery in use. They have a high energy density, no memory effect and a long lifespan. They have a low self discharge rate and can be stored for long periods without losing their charge. Thank you for sharing this blog with us. It was very detailed and informative. I am looking forward to read more such articles in the future.