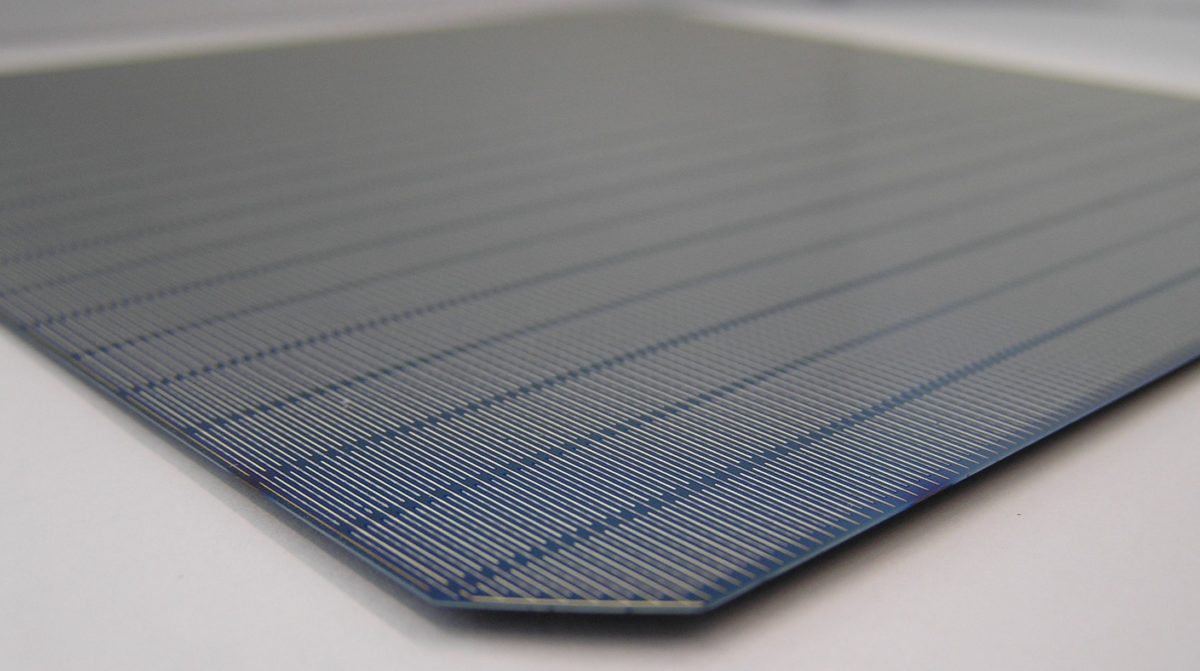

A group of scientists from the Leibniz Universität Hannover and the Institute for Solar Energy Research Hamelin (ISFH) in Germany has developed two different kinds of solar cells based on n-type doped electron-collecting poly-Si on oxide (POLO) junctions with an aluminum-alloyed p+ junction for hole collection — a back-contacted back junction cells (POLO-BJ) and an interdigitated back-contacted cells (POLO-IBC).

“We developed both technologies in parallel, as their process flow is very similar and the development showed many synergies,” Robby Peibst, the research project's corresponding author, told pv magazine. “One of the main motivations for the parallel development was certainly risk minimization, as initially, it was not certain that we would be able to solve the respective challenges. For the POLO-BJ device, for example, the question was whether it was really possible to print an aluminum finger grid so thin that it would be suitable as the front-side metallization of a high-efficiency solar cell, which now seems to be the case.”

The scientists explained that the aluminum-alloyed p+ junction for hole collection is the standard in the manufacturing of PERC solar cells and can be inexpensively formed during the metallization process without the necessity for boron diffusion or silver metallization. Through simulation-based sensitivity analysis on the quality of these hole-collecting junctions, the German group was able to ascertain that the reduction of Al-p+ recombination and resistance is of high importance for both cell structures. “A reduction of pre-factor of the recombination current density from current values of 600 (830) fA/cm2 down to 400 fA/cm2 is compatible with a high-efficiency potential of 25.4% for POLO-IBC and 24.6% for POLO-BJ,” it further explained. “We conclude that the optimization of the quality of the Al-p+ region is a solvable challenge and not a road blocker. An even better quality of the Al-p+ region would facilitate even higher efficiencies.”

The champion POLO-IBC device developed by the academics achieved a power conversion efficiency of 23.71%, an open-circuit voltage of 711.5mV, a short-circuit current of 41.3mA/cm2, and a fill factor of 80.9%. The best-performing POLO-BJ cell reached an efficiency of 22.9%, an open-circuit voltage of 714mV, a short-circuit current of 39.6mA/cm2, and a fill factor of 80.9%.

“The IBC cells required an additional patterning step and the development of a ‘non-standard' module interconnect technology,” Peibst emphasized. “Therefore, POLO-BJ initially seemed to us to be a more obvious upgrade to PERC.” According to him, however, there is currently a significant momentum in the industry towards IBC cells. “Nevertheless, double-side contacted cells will certainly continue to dominate at least in the mid-term. Perhaps POLO-BJ could be the first upgrade of a PERC line, and POLO-IBC a subsequent version,” he affirmed.

The solar cell was described in the paper On the chances and challenges of combining electron-collecting nPOLO and hole-collecting Al-p+ contacts in highly efficient p-type c-Si solar cells, published in Progress in Photovoltaics. “I personally see it as an attractive option that parts of our development can flow into mass production,” Peibst went on to say. “If, for example, we can successfully demonstrate with POLO-BJ that front-side metallization with Al fingers is possible and allows stable module interconnection, this would also be an option for saving silver in n-type TOPCon cells. Our work on Al metallization of poly-Si is also relevant for this purpose.”

The same research group recently conducted a series of numerical simulations to assess how photonic crystals may increase the efficiency of IBC solar cells based on POLO junction at the minus contact of the cell and a hole-selective p+-type POLO junction at the plus contact. The simulated cell was assumed to rely on a standard wafer thickness of 150 μm and the scientists found it may achieve an efficiency of over 28% under normal incident light.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.