From pv magazine USA

The Durable Module Materials consortium (DuraMAT), established by the Department of Energy (DOE) Solar Energy Technology Office (SETO), has been working since its inception in 2016 to improve the use of PV materials.

DuraMAT has awarded $30 million to high-impact projects, and in 2021 was given an additional $36 million by SETO for six more years of funding. The funds will help the consortium continue to develop solar module materials science in pursuit of a 50-year life for PV.

“We are trying to shift into a reliability research mode where we’re directly targeting modules that last 50 years,” said Teresa Barnes, DuraMAT director. “We’re very focused on high-energy-yield modules and making those in a sustainable way. We know there are going to be big material and energy impacts from ramping up deployment as fast as we need for the energy transition. But our question is, ‘How can we do that in a way that’s environmentally sustainable and in a way that our supply chain can keep up?’”

The consortium has five core objectives. First, it seeks to act as a central data resource, collecting and disseminating solar module reliability data, and applying the data to create insights. The DuraMAT database is a centralized source with the ability to ingest, curate, combine, analyze, and manage diverse datasets.

Second, DuraMAT provides fielded module forensics, quantifying and characterizing module failures in outdoor exposures and recording environmental effects. It said one of the biggest hurdles to studying degradation or failure in fielded modules is that frequent absence of a “reference” or control module. This core objective is designed to provide better understanding of PV material durability, and to generate practical, multi-modal data that guides next steps in materials and module design.

As a third objective, the team develops a multi-scale, multi-physics model to accelerate testing and quantitatively assess material degradation.

“We are now shifting our emphasis towards predictive testing and modeling methods that will enable us to assess reliability more quickly and more accurately in new technologies,” said Barnes.

Fourth, it provides module materials solutions, in which the consortium designs, develops, de-risks innovative materials and module architectures to address PV reliability issues. The group has worked to characterize failure modes, develop crack tolerant metallization, and design recyclable backsheets. It has also developed technical requirements and materials guidelines that have enabled thin-film module development.

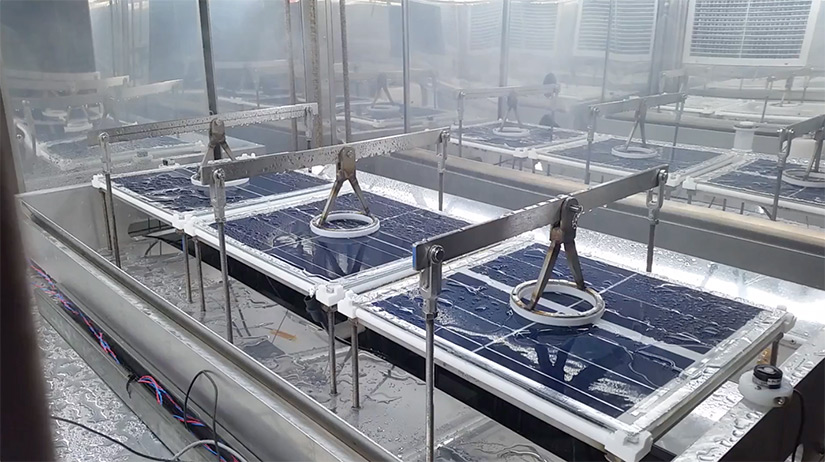

And as a final core objective, the consortium uses disruptive acceleration science to test materials. Using aggressive conditions like pressing modules with rings to simulate bending, or with sound waves to mimic the warping effect of wind, the consortium stress-tests PV modules to see how they would perform in the toughest conditions and over long stretches of time.

“If solar is going to expand and become this ubiquitous technology that we have across our power system, on our houses – and be responsible for 40% of our electricity generation – old technologies are not enough,” said Barnes. “PV modules need to be made more efficient, less expensive, and more sustainably at much larger scale. But we also need to know that these new modules – whether they’re new module designs or new cell technologies like bifacial or tandem cells – will perform predictably in the field.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.