Researchers at the Australian National University (ANU) and the University of Melbourne have compared the firing stability of p-type and n-type passivating contacts based on polysilicon and silicon monoxide (SiOx), which are used in screen-printed solar cells to reduce carrier recombination at the metal/silicon interface.

The scientists explained that the high-temperature firing treatment currently in use as a post-deposition annealing step in the commercial production of screen-printed solar cells must be perfectly gauged to achieve high quality of the poly-Si structures in passivated and contacted regions. “The firing stability of n-type poly-Si passivating contacts has been studied by a number of research groups,” they emphasized. “Few studies have been performed on the firing influence of p-type poly-Si contacts. This paper evaluates the firing stability of p-type poly-Si passivating contacts, and then compares the response of p- and n-type poly-Si to rapid firing and subsequent thermal treatments.”

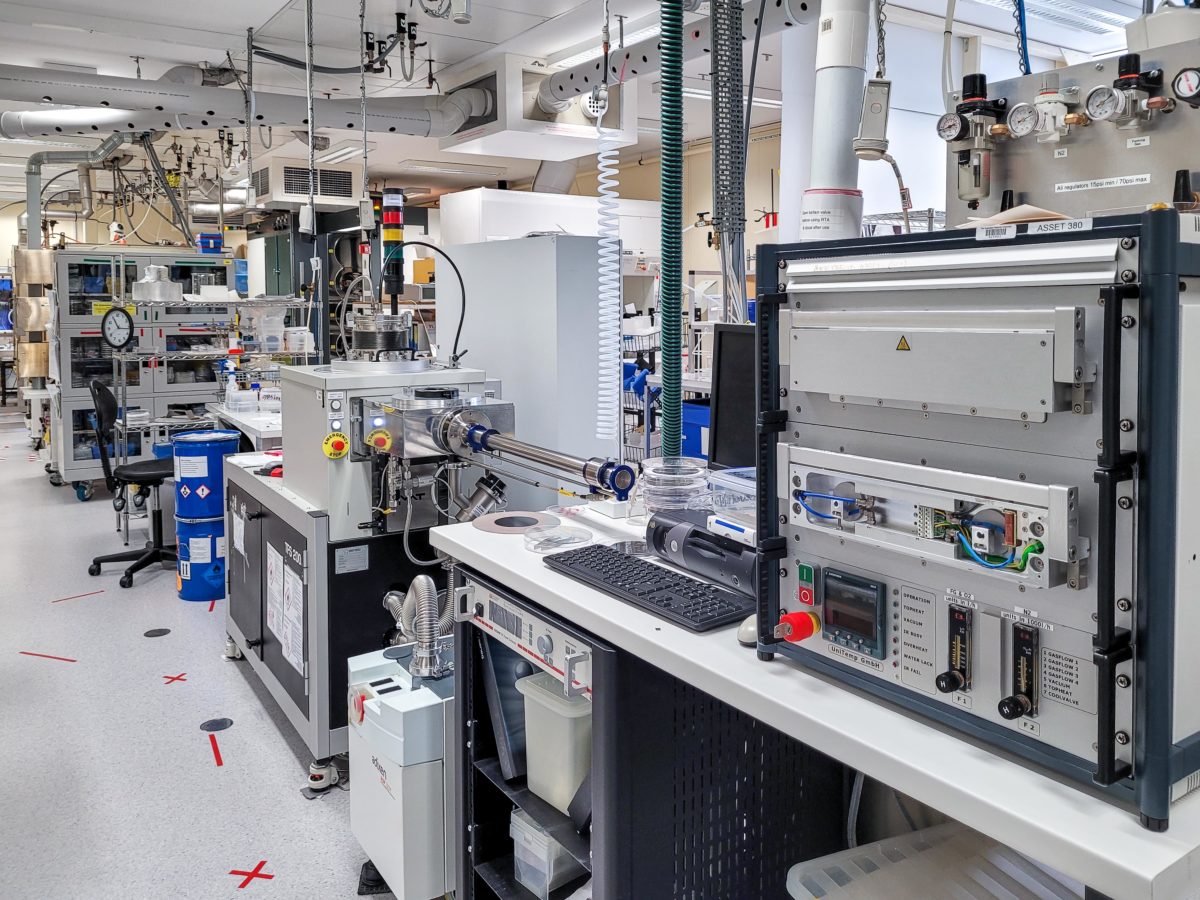

The research group used secondary ion mass spectrometry (SIMS) and Fourier-transform infrared spectroscopy (FTIR) to investigate the root causes for the different firing behavior in samples passivated by p- and n-type poly-Si with similar passivation quality and crystal properties. The firing treatment was performed through rapid thermal annealing (RTA) furnace and the samples were sandwiched between two 180-μm thick dummy wafers.

The temperature for boron diffusion was maintained between 900 and 980 degrees Celsius and the firing operations were performed at 800 degrees Celsius. “The samples subjected to a boron diffusion at 980°C had the best performance before firing, followed by the samples diffused at 950°C and 900°C,” it explained, noting that increasing the diffusion temperature improves the firing stability of the p-type poly-Si/SiOx contacts. “Adjusting the diffusion temperature appears to show a lesser impact on p-type poly-Si than on n-type poly-Si. In contrast to the severe firing impact on lightly doped n-type poly-Si, only small surface degradation was detected on lowly doped p-type poly-Si after 800°C firing.”

The academics believe that the passivation quality of the contacts after the firing operations may depend on the amount of hydrogen released during the process from the dielectric films to the SiOx interlayer, as well as excess hydrogen around the SiOx. “This speculation was also supported by the increased degradation extent after injecting more hydrogen, as well as the recovered current density after reducing the hydrogen content around the SiOx thin layer via a 300°C N2 anneal after the removal of fired silicon nitride (SiNx),” they stated. “In contrast to n-type poly-Si, the current density of p-type poly-Si was recovered after injecting more hydrogen to the poly-Si/SiOx stack by the re-hydrogenation treatment, which could possibly indicate that there was no excess hydrogen in p-type poly-Si/SiOx, possibly attributed to the lower effective diffusivity of atomic hydrogen in p-type materials.”

The scientists concluded that the diffusivity of hydrogen in p-type poly-Si is lower than in n-type, which prevents the accumulation of excess hydrogen around the oxide which deteriorates the passivation quality. “The results extend our understanding of the firing effect on poly-Si/SiOx structures, which may help to further improve the performance of doped poly-Si contacts,” they added.

Their findings are available in the paper Comparison of firing stability between p- and n-type polysilicon passivating contacts, published in Progress in Photovoltaics.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.