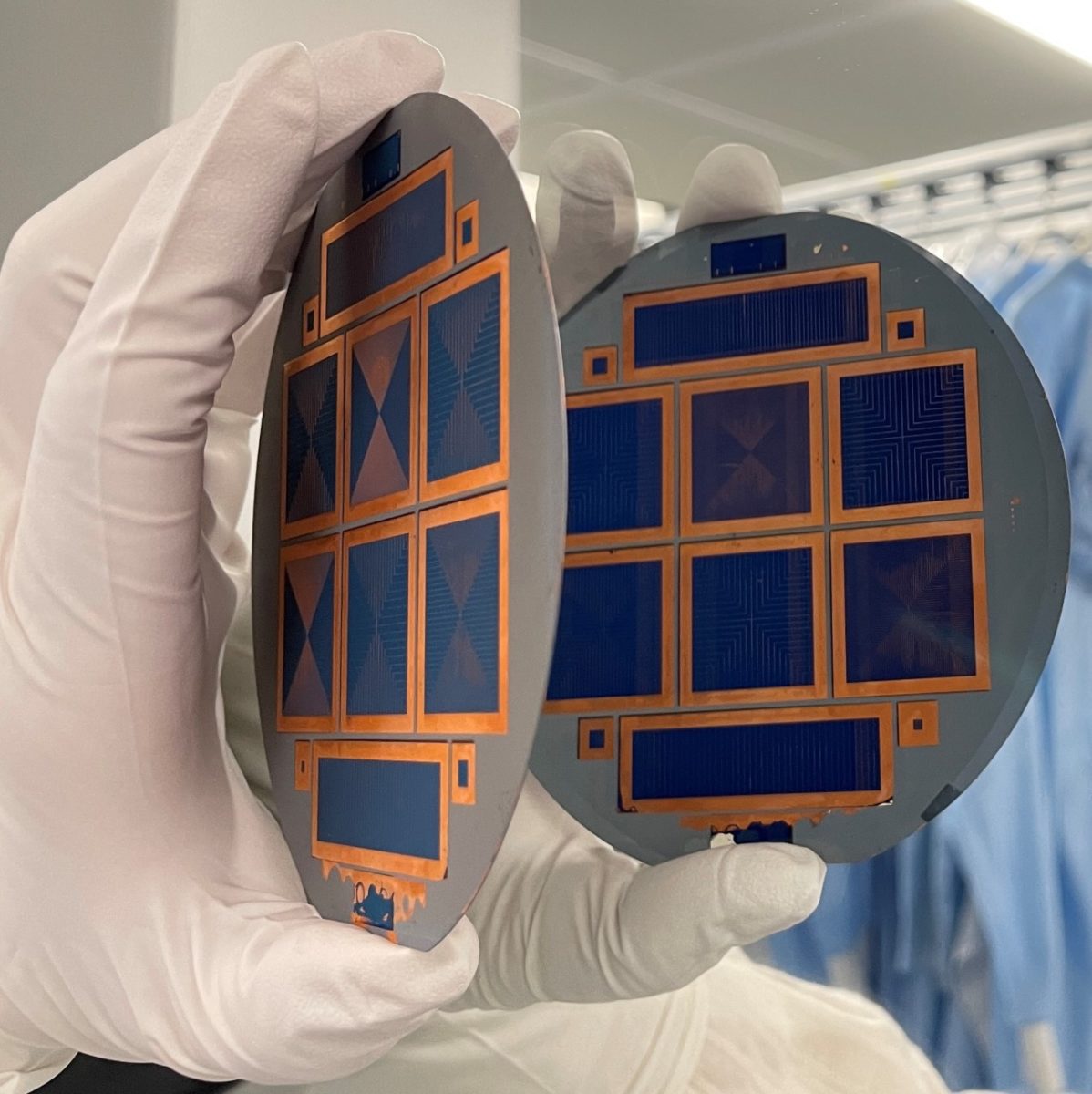

An international research group has achieved a 22.1% power conversion efficiency in a bifacial heterojunction crystalline solar cell fabricated through copper (Cu) plating metallization. “We developed the cell by using controllable simultaneous bifacial copper plating on the two sides of a wafer,” the research's corresponding author, Can Han, told pv magazine. “A new type of hybrid-shaped copper finger was plated, and the best Cu-plated bifacial silicon heterojunction solar cell showed a front side efficiency of 22.1% and a bifaciality factor of 0.99.”

The scientists used two sub-three-electrode electrochemical cells in a simultaneous bifacial Cu-plating process and cyclic voltammetry (CV), which is an electrochemical technique commonly utilized to analyze the reduction and oxidation processes of molecular species, was applied to control that the process was well controlled. “The applied potential on one sub-cell on one side of the wafer would unavoidably influence the other conductive side of the wafer, thus somehow interacting with the electrochemical process in the other sub-cell on the other side of the wafer,” they explained. “In other words, the bifacial Cu deposition rates on both sides of the wafer can be controlled at the same level, but they are not the same as that of monofacial deposition.”

They also fabricated a new type of hybrid-shaped Cu finger consisting of a rectangular bottom part and a round top part and integrated it into the cell through a 2-step electrochemical deposition process. “With this approach, we improved finger adhesion and achieved relatively uniformly distributed Cu fingers,” they also stated.

The performance of the Cu-plated solar cell was compared to that of a reference device built by screen printing (SP) and relying on silver (Ag) contacts. The analysis showed that the copper-based device was able to outperform the reference cell both optically and electrically. “Specifically, the cell with SP-Ag showed lower open-circuit voltage, with respect to the Cu-plated cell,” the research team specified. “This could be partially caused by the Ag penetration into wafer bulk, which induces more recombination centers at the metal and silicon interfaces.”

The Cu-plated cell achieved an efficiency of 22.02%, an open-circuit voltage of 716mV, a short-circuit current of 38.07mA cm2, and a fill factor of 80.76%. The SC cell achieved a slightly higher efficiency of 22.12% and a lower open-circuit voltage of 710mV, with the short-circuit current and fill factor being 37.24 mA cm2 and 76.11%, respectively.

A full description of the solar cell is provided in the paper Controllable Simultaneous Bifacial Cu-Plating for High-Efficiency Crystalline Silicon Solar Cells, published in RRL Solar. The research group is formed by scientists from the Delft University of Technology (TU Delft) in the Netherlands and Nankai University in China.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.