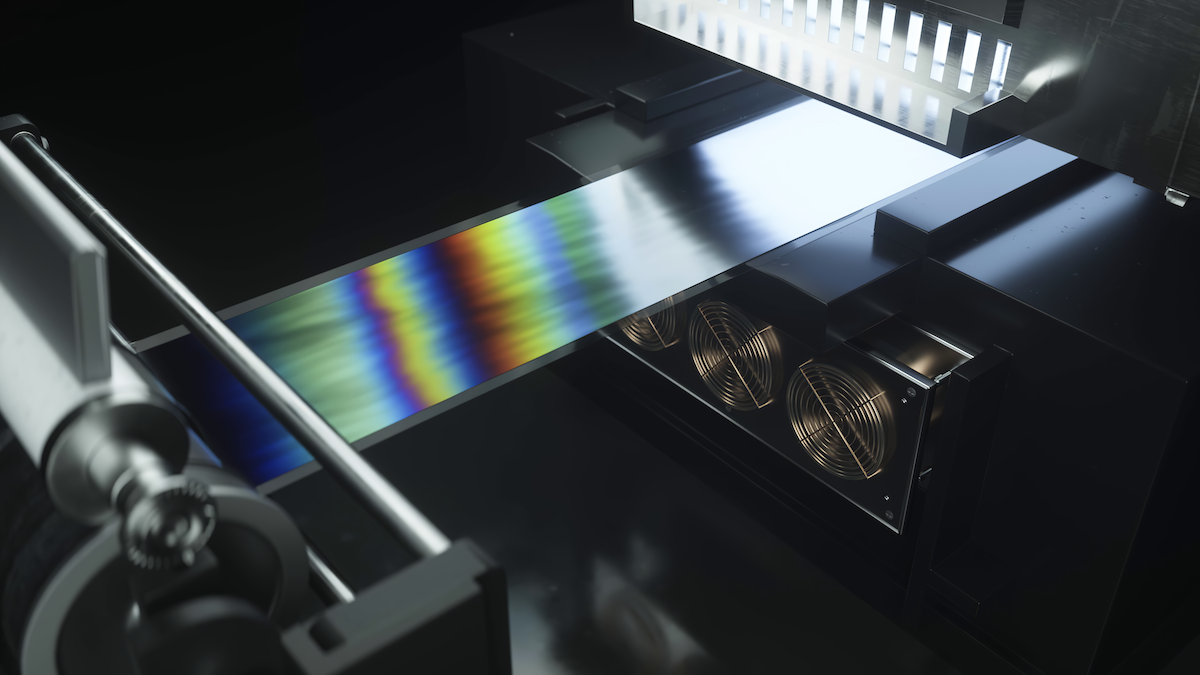

UK-based flexible PV module manufacturer Power Roll yesterday inaugurated its pilot solar film manufacturing facility in County Durham, in North East England.

“The factory is planned to reach a capacity of 30 MW by the end of the year,” a spokesperson from the company told pv magazine. “The main purpose of the plant is to demonstrate the manufacturing process to Power Roll’s licensing partners as well as producing pilot output for testing and demonstration.”

Power Roll said it uses low-cost roll-to-roll manufacturing processes on top of its patented microgroove patterns to produce what it calls an ultra-low-cost solar PV solution. “This simplicity of production is core to Power Roll’s plans to license high-scale manufacturing to local companies. This will enable manufacturing of solar film to scale up globally. We will fully demonstrate our technology at our Durham facility but partnerships with large companies in the UK and overseas will see capacity expand in the next few years,” the spokesperson went on to say.

Power Roll added that it was in advanced negotiations with manufacturing partners to scale-up, in parallel with its own factory development.

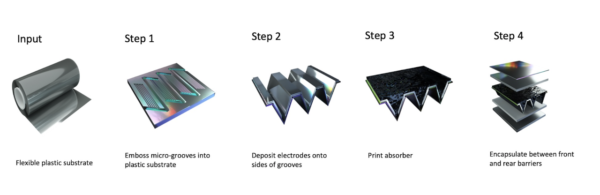

The manufacturing process consists of four different steps. The company first embosses ultra-thin micro-grooves into a flexible film and then embossed pattern on the solar film is then imprinted in polyethylene (PET) film. This process is described as similar to the creation of holograms, such as those on credit cards, and uses the same machinery. In a second step, the microgroove walls are coated with conductive metals, with each groove wall being coated with a conductive metal to channel the sun’s energy across the film for extraction.

Image: Power Roll

The 1-micron wide micro-groves are the core element of the film technology, as they are claimed to eliminate the need for several expensive process steps needed by other solar designs. “The micro-groves are specifically designed to be manufactured using high-speed roll-to-roll processes and because each solar cell and module are microscopic, the impact of any damage is limited to the specific area impacted and does not impact a larger area as in current PV solutions,” the spokesperson emphasized.

“Emerging solutions such as Power Roll’s flexible film will enable solar to be deployed more easily in the built environment, off-grid, on vehicles and other applications where traditional silicon solar panels are too heavy or too expensive to be used,” the company said in a statement. “When the film is produced at scale, manufacturing costs are forecast to be as low as a tenth of the cost of other flexible PV. Solar film can be deployed on warehouses and agricultural sheds where the roofs are not strong enough to bear the weight of traditional solar panels.”

Power Roll was able to raise around £20 million in investment rounds since it was founded. Through the latest round held this month, is raised £5.8 million.

*The article was updated on February 28 to specify that the manufacturing facility is a pilot factory.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

This is a very great achievement. A very remarkable advancement on the PV industry…

Hope the increase their production capacity base next year.

These factories need to be invested in throughout the uk and possibly with a law change get solar on every suitable roof in the uk.