A research team from the Chinese Academy of Sciences (CAS) has built an all-polymer organic solar cell based on high–quality blend films with enhanced crystallinity and inter–penetrating nanofibers network morphology.

“The device could be used in indoor photovoltaics, smart power generation windows, and mobile wearable devices in the future,” researcher Jingxia Wang told pv magazine.

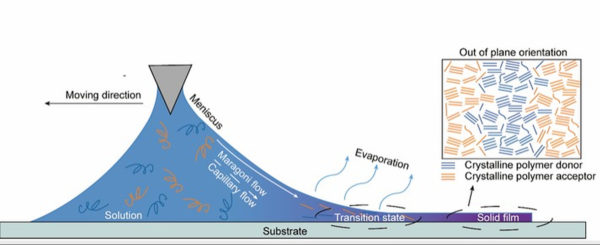

The scientists used a special meniscus–assisted coating (MAC) technique. The method is commonly used in the deposition of semiconducting polymers of different kinds and relies on the use of a dynamic meniscus during the blade-coating process.

“By directionally moving the meniscus, it transforms from a symmetrical shape into an asymmetric geometry under the dual action of the shear force and the adhesion force of the substrate,” the researchers explained. “Finally, a high–quality blend film is deposited on the substrate accompanied by the uniform evaporation of the solute.”

They said it's important to control the liquid advancing speed and maintain the dynamic balance of the transition state between the solution and solid film. They claim this allows the formation of a binary nanofiber network morphology with crystallization enhancement.

Image: Chinese Academy of Sciences

This printing strategy, they went on to say, is used to achieve the highly aligned conjugated polymer thin-films for high-mobility organic field-effect transistor and, ultimately, to optimize the morphology of the cell's active layer to achieve higher efficiencies.

They fabricated the device on a substrate made of PEDOT:PSS, coated on indium tin oxide (ITO) glasses, with a polymer donor known as PM6 and a polymer acceptor called PY–IT. They chose these on the basis of their well-matched energy levels and absorption spectra.

Through the meniscus-assisted process, the Chinese group was able to produce a champion solar cell with a power conversion efficiency of 15.53%, an open circuit voltage of 0.945V, a short-circuit current of 23.27mA/cm2, and a fill factor of 70.77%. For comparison, a reference solar cell fabricated via common spin coating reached a lower efficiency of 14.58%, an open-circuit voltage of 0.936V, a short-circuit current of 22.54 mA/cm2, and a fill factor of 69.10%.

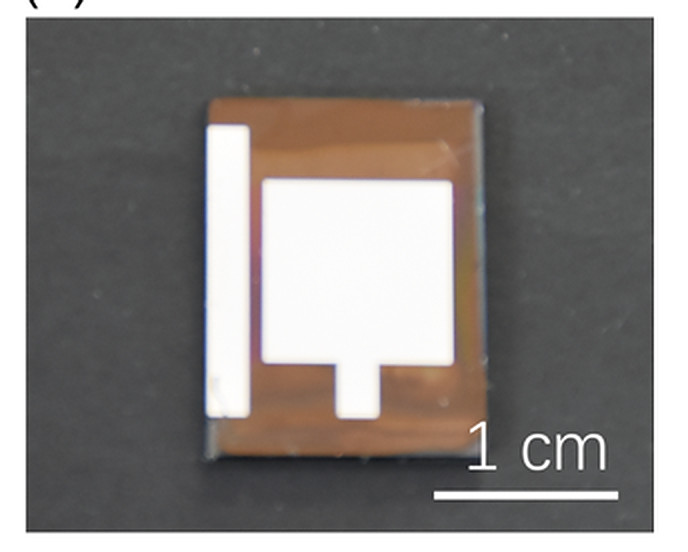

“To the best of our knowledge, the power conversion efficiency of 15.53% from MAC is the highest among the solution-printing-based all-polymer solar cells,” the scientists stated, noting that they were also able to build a larger device with an active area of 1cm2, with an efficiency of 12.55%.

They described the solar cell in “The Meniscus-assisted-coating with Optimized Active Layer Morphology towards Highly Efficient All-polymer Solar Cells,” which was recently published in Advanced Materials.

“This work not only provides a simple and efficient solution printing method for the preparation of all-polymer solar cells, but also gives constructive theoretical guidance at different shear rates,” Wang concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.