Scientists led by the Karlsruhe Institute of Technology (KIT), in Germany, have used a colorization method based on inkjet-printed reflective pigments to fabricate small-area perovskite solar modules for application in building-integrated photovoltaics (BIPV).

The researchers said they adapted the conventional colorization approach used for crystalline silicon photovoltaics to solar cells based on perovskite. It consists of inkjet-printing pigment-based colored layers on the plain glass side of pre-patterned indium tin oxide (ITO) glass substrates and then depositing the PSC layer stack on the ITO side of the substrate. “This approach of colorization is, with regards to fabrication, mostly independent on the solar cell architecture,” they explained.

The academics used pigment-based inks of white, cyan, magenta, and yellow color. A reflective white interlayer was embedded between the perovskite solar cell and the printed pigment film, to obtain a color impression as close as possible to the targeted color while also increasing lightness. “The projections of the 3D representation show that the color impression of the PSCs with white interlayer is very close to the targeted color on a white background and significantly more brilliant and colorful than without the white interlayer,” they emphasized.

The performance of the solar cells was analyzed under standard illumination conditions and that of the cells colored with layers of magenta and yellow suffered the lowest yield losses – between 10 and 30% – compared to the efficiency of reference uncolored solar cells. Cyan-colored devices registered the largest losses, in the range of 50 to 70%. “These differences originate from the significantly differing parts of the solar spectrum that are reflected and therefore lost for photo-absorption in the perovskite,” the research group stated.

“Until now, when manufacturing colored perovskite solar cells, the color impression of the devices for the viewer was heavily dependent on the angle of the incident light,” explained the research project coordinator, Helge Eggers. “With our method, on the other hand, the color used is almost entirely independent of the angle of incidence of the sunlight but always looks the same.”

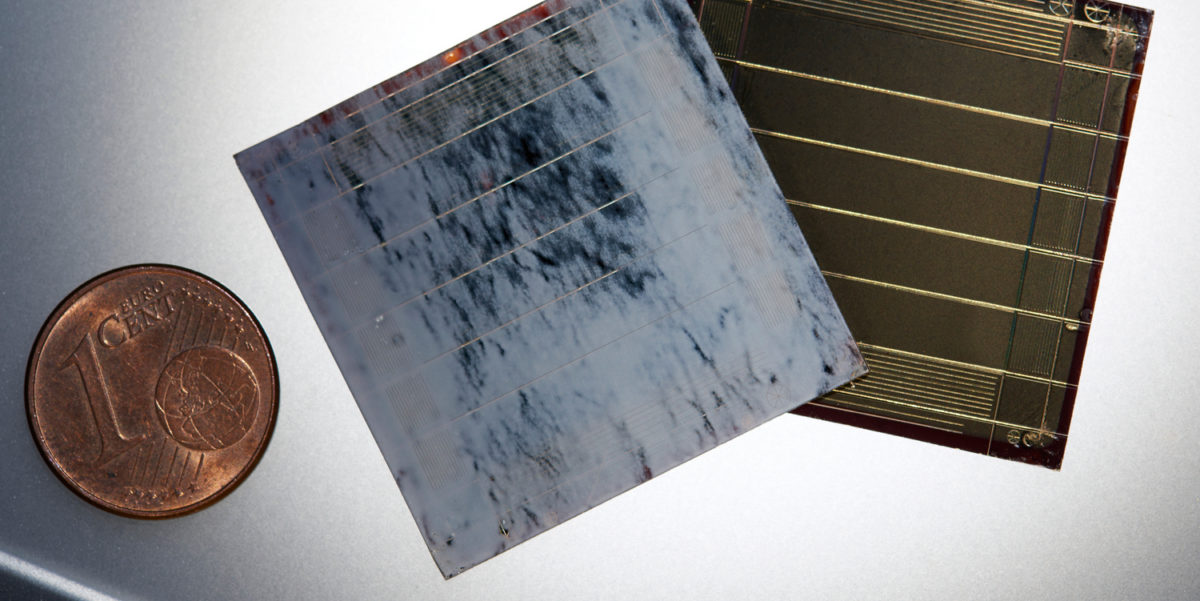

Five interconnected solar cells were used to fabricate a colorized small perovskite solar module in white marble optic displays. The module has a total area of 9cm2 and an active area of 4cm2. Its power conversion efficiency was found to be 13.9%, which is 88.5% of the average of uncolored reference devices, with an efficiency of 15.7%. “Our prototype highlights that a high aesthetic value does not necessarily go hand in hand with an immense loss in performance,” the scientists said. The modules colored with bright mono-colored cyan, magenta, yellow, blue, red, and green all achieved efficiencies close to 12%.

All the details on the coloring technique can be found in the paper “Perovskite Solar Cells with Vivid, Angle-Invariant, and Customizable Inkjet-Printed Colorization for Building-Integrated Photovoltaics,” published in RRL Solar.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.