Lithium-oxygen, or lithium-air batteries (LABs), are one of many pathways to improving today’s energy storage technologies. Lithium and other metal-air batteries are favored in research for their potential for high energy densities, but low efficiency and poor cycle lifetimes have proven to be tough obstacles to overcome in developing such technologies.

With this in mind, scientists from Japan’s National Institute for Materials Science and Softbank have developed a rechargeable lithium-air battery. They claim it has an energy density that greatly exceeds that of conventional lithium-ion batteries.

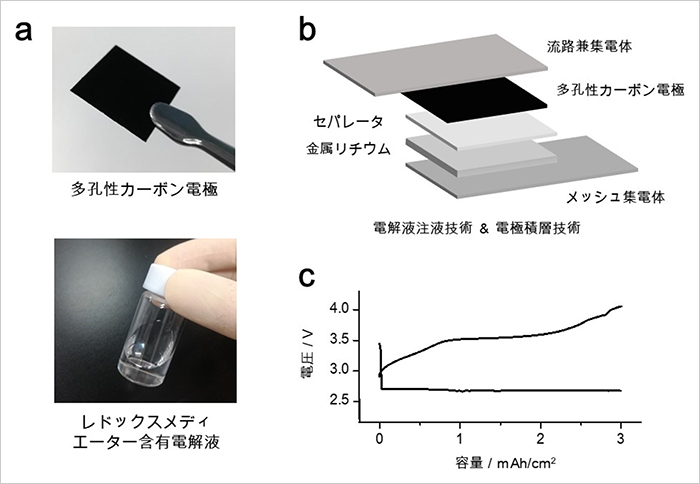

Like other LABs built at the research level, the Japanese consortium's battery relies on lithium for the negative electrode and oxygen for the positive porous carbon electrode. The 10-cell stacked device has a size of 4 cm x 5 cm and single-layered cells with a 2 cm x 2 cm electrode.

“In the stacked cell configuration, oxygen needs to be transported in the horizontal direction in the gas diffusion layer,” the scientists explained. “Then, oxygen needs to be further transported to the vertical direction to go through the whole part of the positive electrode.”

When operated at room temperature, the champion battery exhibited a weight energy density of 500 Wh/kg, which is about twice that of current lithium-ion batteries. The performance has been described as the highest in the world in terms of energy density and number of cycles.

“Although there are many reports that demonstrate the successful operation of a LAB with prolonged discharge/charge processes for more than 100 cycles, their energy density at the practical cell level was lower than 50 W h kg−1. In contrast, for the LABs with an energy density over 300 W h kg−1, the cycle number was less than 20 cycles,” the researchers said.

They claim that the storage device has potential applications in residential power storage systems, electric vehicles, drones, and Internet-of-Things (IoT) devices. They described it in “Criteria for evaluating lithium-air batteries in academia to correctly predict their practical performance in industry,” which was recently published in Materials Horizons.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

A commercial battery needsa t least say 1000 cycles. Judging by the authors’ figure 2, nobody is anywhere near his today for lithium-air chemistry.. Workable superbatteries for aircraft are still many years away.

So, they have achieved an energy density 66 times lower than hydrogen?

So, how many cycles does theirs have? Or do we need to read the whole whitepaper?