Researchers at the Solar Energy Research Institute of Singapore (SERIS) have proposed a new design for shingled solar modules that they claim could make these products less susceptible to shading and hotspots, which remain the main hurdles to overcome for wider commercial adoption of this PV technology.

“Rather than proposing a particular interconnection or module architecture as a one-size-fits-all solution, our work offers a design framework based on minimizing potentially dangerous hotspot temperatures while granting manufacturers the flexibility to play around with different design parameters,” the research's corresponding author, Carlos Clement, told pv magazine. “Ideally, the way this would work is a manufacturer chooses a cell technology, may it be p-type PERC or whichever they choose, and through our model, one would generate a matrix of module parameters such as string length, cell fraction and number of strings, where the hotspot risk for each specific combination is quantified. The analysis can also be performed in the opposite direction, with specific module characteristics constrained first and then suitable cell technologies and characteristics determined afterwards.“

In the paper “Design of shading- and hotspot-resistant shingled modules”, which was recently published in Progress in Photovoltaics, the SERIS team developed an electrothermal model intended at creating a framework for the design of shingled panels that are resistant to shading and hotspots. “For the purposes of this study, we chose to model and test shingled modules manufactured from pPERC cells that were cut into one-fifth pieces via thermal laser separation for improved mechanical properties,” the scientists specified. “From our previous study, we learned that p-type cells exhibit an illumination-dependent effect on their leakage current as the cell approaches breakdown.”

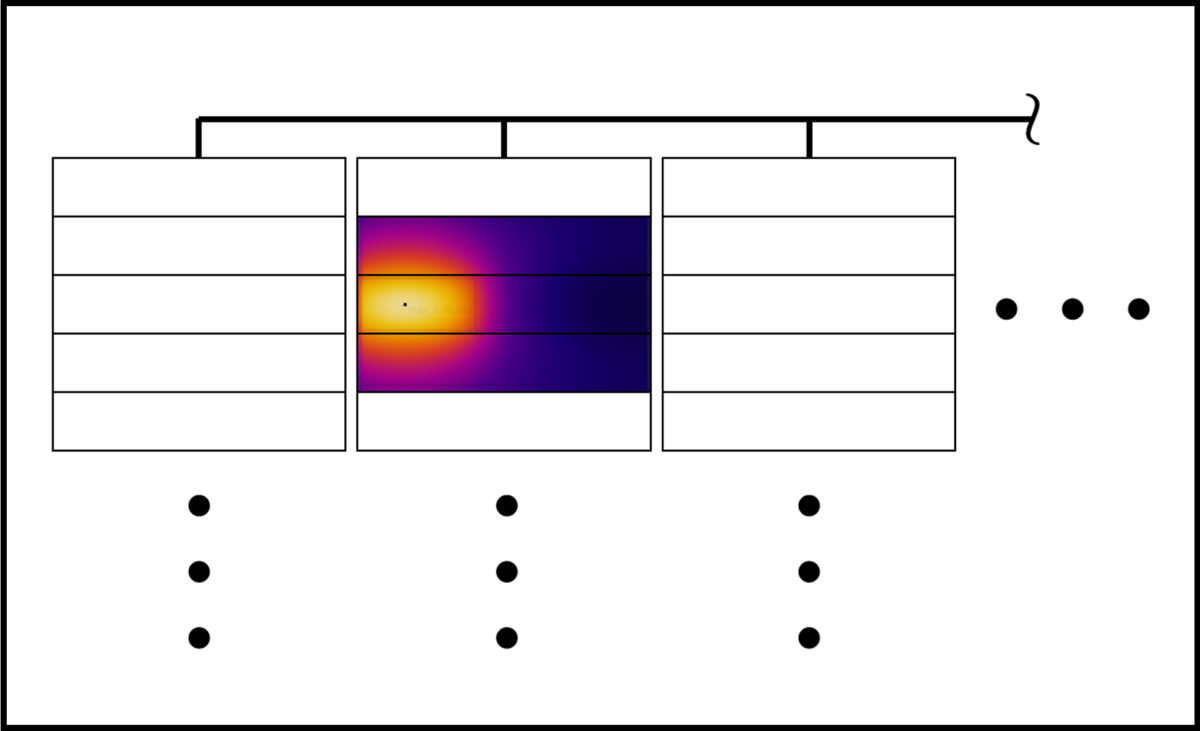

Through the modeling approach, the researchers initially simulated a shingled module's power and hotspot response to shading. They built mini-modules from 12 shingles that were laminated on 20x20cm glass with the same encapsulant and backsheet used in full-sized modules. These panels were tested under negative voltages and standard irradiation conditions and their cell parameters were extracted.

The model was then validated through experimental data. “The accuracy of this model depends largely on how well our split-cell subcircuit can capture cell behavior at negative voltages approaching breakdown,” they further explained, noting that a simulation was performed on module power responses for different configurations of shingled modules. The electrothermal model developed was found to adequately capture the hotspot and shading response of the panels.

These insights were then used to set up the above-mentioned framework for designing hotspot-resistant shingled modules. This requires, first, understanding, via Monte Carlo simulations (MCS), which input cell characteristics are more suitable in a multivariate system where parameters are varying together. “From the perspective of minimizing power loss, it is advantageous to have cells which have more leakage current,” the academics emphasized. “This can be explained by how larger leakage currents allow the shaded cell to match the current of the other series-connected cells without being pushed further into reverse bias.”

According to the research group, raising the number of strings determines, for the shaded cells, a delay in bypass diode activation and larger reverse voltages, which in turn result in higher maximum temperature measured in the cell itself. This, in their view, makes string length one of the most influential design levers in determining hotspot temperature. With an increasing number of parallel strings per block, the shaded string becomes able to operate at lower currents, and lower hotspot temperature.

“The work outlined here is perfectly compatible with existing manufacturing techniques for shingled modules,” Clement told pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Amazing new tech coming out each week! Just imagine what will be available in a couple years!