Organic PV covers a range of different materials that have maintained plenty of interest from researchers, but not yet achieved the levels of performance that would be needed to attract commercial interest, save for a few niche applications.

While organic PV presents opportunities for low cost and low carbon footprint manufacturing, balancing efficiency with long term stability is still a challenge, and the best performing cells in terms of efficiency most often rely on solvents that are highly toxic and difficult to work with in manufacturing.

A collaboration between scientists at Linköping University in Sweden and China’s Soochow University looked to address these issues, working on an organic solar cell made from a material known as Y6. For solution processing of this cell material, they chose paraxylene, which they say has no toxic ingredients and a higher boiling point making it easier to use in manufacturing.

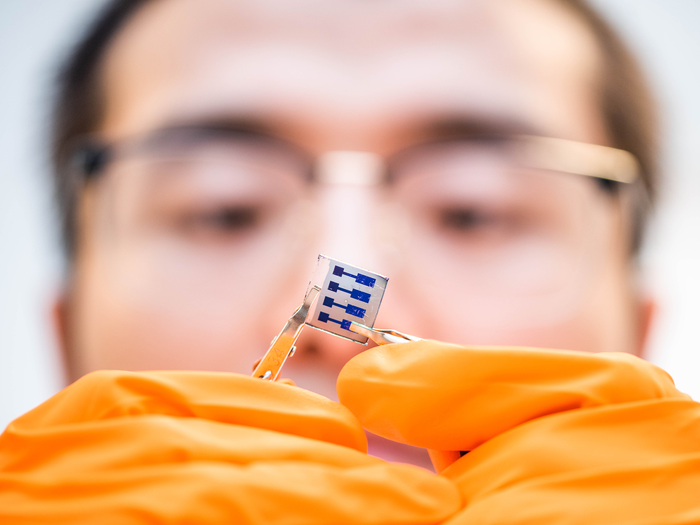

With this solvent, the group was able to manufacture laboratory-sized solar cells with an efficiency better than 17%, as well as a 36cm² device that reached 14% efficiency. The cells are described in the paper A guest-assisted molecular-organization approach for >17% efficiency organic solar cells using environmentally friendly solvents, published in Nature Energy.

“This is a major step towards large-scale industrial manufacture of efficient and stable organic solar cells, say Linköping University researchers Feng Gao and Rui Zhang. “Our results now open for the manufacture of organic solar cells at larger scales for outdoor use.”

Guest molecule

Key to these achievements, the researchers say, was the addition of a guest molecule ‘BTO’, which served to keep the Y6 molecules closely packed and ordered within the solvents. Keeping the structure uniform in this way benefits the cell efficiency, improves long-term stability and allows for the fabrication of larger area devices.

As well as paving the way for industrial development of organic solar cells, the group says its approach could be applied to other materials. “Our strategy leads to clear design rules for optimising the interaction between organic donors and acceptors in multicomponent blends, meeting the critical requirements for future development of organic photovoltaic technology,” said Professor Yaowen Li, Soochow University.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.